Mokhoa oa ho Bopa oa Indasteri Ceramic Machining

Lisebelisoa tsa mechine tse entsoeng ka lirafshoa tsa morao-rao tsa indasteri li sebelisoa haholo ka lirafshoa tsa sesole, lirafshoa tsa masela, lirafshoa tsa elektronike le tsa motlakase, joalo-joalo, na ua tseba hore na lik'hemik'hale tsa indasteri li thehoa joang? Mekhoa eo ke efe? Pintejin Ceramics e tla u bolella.

Ho na le mefuta e mengata ea li-ceramics tsa indasteri, tse arotsoeng ho latela lisebelisoa tse tala, li arotsoe ka letoto le latelang:

- --- Ceramics ea oksijene: haholo-holo lirafshoa tsa alumina, zirconia ceramics, mullite ceramics, joalo-joalo;

- --- Carbide ceramics: haholo-holo silicon carbide ceramics, titanium carbide ceramics, boron carbide ceramics, joalo-joalo;

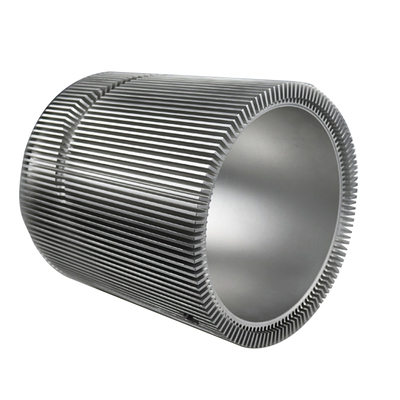

Mechini e sebetsang ea ceramic ea indasteri, ntle le metjhini e meng ea ho sila, lisila le metjhini e betliloeng e nepahetseng ea CNC, metjhini ea ho sila le eona ke mechini ea bohlokoa ea ho lokisa ceramic, e ka fihlelang ts'ebetso e nepahetseng ea ceramic e phahameng haholo.

Ho sila: Hajoale, boholo ba lirafshoa tsa liindasteri li sebelisa haholo ho sila. Ka lebaka la boima bo phahameng ba lisebelisoa tsa 99 tsa alumina ceramic, thepa ea daemane (ea tlhaho le ea maiketsetso) hangata e sebelisoa bakeng sa mabili a sila, ha thepa ea B4C e sebelisoa haholo-holo bakeng sa ho sila.

Patlisiso e bonts'a hore ts'ebetsong ea ho sila lirafshoa tsa liindasteri tse 99, lisebelisoa tsa ceramic tsa indasteri li kenyelletsa haholo mekhoa ea ho tlosa lijo-thollo, ho robeha ha brittle, exfoliation ea lintho tse bonahalang, le microfracture ea moeli oa lijo-thollo.

Mekhoa ea mantlha ea ho etsa li-ceramics tsa indasteri:

- --- Dry pressing molding: Ho na le mefuta e 'meli ea mechine ea khatiso bakeng sa theknoloji ea ho bopa e omileng, hydraulic le mechanical, e ka bang semi-automatic kapa ka ho feletseng. Ha khatello e phahame haholo, ke 200Mpa. Sephetho se ka fihla likotoana tse 15 ho isa ho tse 50 ka motsotso. Ka lebaka la khatello e tšoanang ea stroke ea mochine oa khatiso oa hydraulic, bophahamo ba likarolo tse hatelitsoeng bo fapane ha ho tlatsa phofo ho fapane. Leha ho le joalo, khatello e sebelisoang ke mochine oa khatiso oa mechine e fapana le palo ea ho tlatsa phofo, e ka lebisang habonolo ho se tšoane ha shrinkage ea dimensional ka mor'a ho sintering, e amang boleng ba sehlahisoa. Ka hona, kabo e tšoanang ea likaroloana tsa phofo nakong ea ho hatella ka ho omella e bohlokoa haholo bakeng sa ho tlatsa hlobo.

- --- Mokhoa oa ho bopa: ho bopa ha grouting ho nka hlobo ea plaster, e theko e tlase ebile e bonolo ho etsa likarolo tse nang le boholo bo boholo le sebopeho se rarahaneng. Senotlolo sa grouting ke ho lokisetsa boitsebiso. Hangata metsi a sebelisoa e le sesebelisoa sa solvent, ebe joale ho kenngoa sekontiri le sekontiri. Ka mor'a nako e telele ea ho sila, moea o felile, ebe o tšeloa ka har'a hlobo ea samente. Ka lebaka la ho kenngoa ha metsi ke capillary ea hlobo ea plaster, slurry e tiisa hlobo. Ha li-grouting tse sekoti, ha lebota la hlobo le monya slurry ho isa botenya bo hlokahalang, slurry e feteletseng e hloka ho tšolloa. E le ho fokotsa ho fokotseha ha 'mele o motala, slurry e phahameng ea concentration e lokela ho sebelisoa ka hohle kamoo ho ka khonehang.

- --- Mokhoa oa sintering le oa ho bopa: Mokhoa oa tekheniki oa ho tiisa 'mele oa ceramic oa liindasteri tsa granular le ho etsa lisebelisoa tse tiileng o bitsoa sintering. Sintering ke mokhoa oa ho tlosa likheo pakeng tsa likaroloana tsa 'mele, ho tlosa khase e nyenyane le litšila, le ho etsa hore likaroloana li hōle le ho kopana ho theha ntho e ncha.

Khampani ea Pintejin ceramic e fana ka mechine ea ceramic litšebeletso ho lienjineri, baetsi ba lihlahisoa, baqapi, le tse ling ka bokhoni ba rona ba ka tlung. Mabenkele a rona a boleng bo holimo a ISO9001: 2015 le ITAF 16949 a ka etsa moralo ofe kapa ofe oa tloaelo, o bonolo kapa o rarahaneng. Re fana ka li-prototypes tse potlakileng tsa ceramic, machining a li-batch tse nyane, le tlhahiso e phahameng haholo, ka litaelo tsohle tse fanoang ke Pintejin ho tloha qetellong ho isa qetellong. Re amohela litšoantšo tsa tekheniki 'me re na le lihlopha tsa ts'ehetso ho netefatsa hore u fumana likarolo tsa hau tse entsoeng ka mochini kapa hlobo ka boleng le ka nako.

webosaete ea rona ea mochini oa ceramic:https://machiningceramic.com/

3, 4 le 5-axis e nepahetseng CNC lisebelisoa ditshebeletso tsa aluminium machiningberyllium, tšepe ea carbon, magnesium, mochini oa thaethaniamo, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite le lehong. E khona ho etsa likarolo tsa machining ho fihlela ho 98 in. turning dia. le +/-0.001 in. mamello e otlolohileng. Mehato e kenyelletsa ho sila, ho cheka, ho bora, ho ts'oara, ho tlanya, ho theha, ho loha, ho loants'a, ho qhekella, ho reaming le ho khaola laser. Litšebeletso tsa bobeli tse kang ho kopanya, ho sila ho se na setsi, ho phekola mocheso, ho pata le ho cheselletsa. Prototype le tlhahiso e tlase ho isa ho e phahameng e fanoang ka boholo ba li-unit tse 50,000. E loketse matla a mokelikeli, pneumatics, hydraulics le phunyang ditshebediso. E sebeletsa sebaka sa lifofane, lifofane, sesole, bongaka le ts'ireletso. sales@pintejin.com ) ka kotloloho bakeng sa projeke ea hau e ncha.

3, 4 le 5-axis e nepahetseng CNC lisebelisoa ditshebeletso tsa aluminium machiningberyllium, tšepe ea carbon, magnesium, mochini oa thaethaniamo, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite le lehong. E khona ho etsa likarolo tsa machining ho fihlela ho 98 in. turning dia. le +/-0.001 in. mamello e otlolohileng. Mehato e kenyelletsa ho sila, ho cheka, ho bora, ho ts'oara, ho tlanya, ho theha, ho loha, ho loants'a, ho qhekella, ho reaming le ho khaola laser. Litšebeletso tsa bobeli tse kang ho kopanya, ho sila ho se na setsi, ho phekola mocheso, ho pata le ho cheselletsa. Prototype le tlhahiso e tlase ho isa ho e phahameng e fanoang ka boholo ba li-unit tse 50,000. E loketse matla a mokelikeli, pneumatics, hydraulics le phunyang ditshebediso. E sebeletsa sebaka sa lifofane, lifofane, sesole, bongaka le ts'ireletso. sales@pintejin.com ) ka kotloloho bakeng sa projeke ea hau e ncha.

- 5 selekane Machining

- Cnc siloa

- Cnc fetola

- Mechini ea Machining

- Ts'ebetso ea Machining

- Phekolo ea bokaholimo

- Metal Machining

- Machining ea polasetiki

- Phofo Metallurgy hlobo

- Ho Casting

- Likarolo tsa Gallery

- Likarolo tsa Auto Metal

- Likarolo tsa mechine

- Sesebelisoa sa mocheso oa LED

- Likarolo tsa Kaho

- Likarolo tsa mobile

- Likarolo tsa Bongaka

- Likarolo tsa Elektroniki

- Machining e etselitsoeng

- Likarolo Tsa Baesekele

- Aluminium Machining

- Thaethaniamo Machining

- Lisebelisoa tsa Stainless Steel

- Koporo Machining

- Koporo Machining

- Super motsoako Machining

- Peek Machining

- Machining a UHMW

- Tlanya Machining

- Machining a PA6

- PPS Machining

- Mochini oa Teflon

- Inconel Machining

- Sesebelisoa sa Sesebelisoa sa Steel

- Boitsebiso bo Eketsehileng