Mokhoa oa ho Fokotsa Litšenyehelo tsa ho Etsa Lintho Nakong ea CNC Lathing

2023-09-26

Le lefatseng la tsa sebetsa ka ho nepahetseng machining, CNC (Computer Numerical Control) lathing ke ts'ebetso ea mantlha e phethang karolo ea bohlokoa tlhahisong ea likarolo tse fapaneng. Leha ho le joalo, litšenyehelo tsa ho etsa thepa ho sebelisa CNC lathing e ka ba taba e kholo ho likhoebo tse ngata. Tataisong ena e felletseng, re tla hlahloba maano le mekhoa e fapaneng ea ho fokotsa litšenyehelo tsa tlhahiso nakong ea CNC lathing.

kutlwisiso Lathing ea CNC

Pele re hlahloba maano a ho fokotsa litšenyehelo, ha re qaleng ka ho utloisisa metheo ea CNC lathing. CNC lathing ke mokhoa oa tlhahiso ea subtractive o kenyelletsang ho tlosoa ha thepa ho tloha mosebetsing ho etsa sebopeho kapa karolo e lakatsehang. E sebelisoa haholo liindastering tse kang sefofane, likoloi, le lisebelisoa tsa bongaka, har'a tse ling, ka lebaka la ho nepahala le ho feto-fetoha ha maemo. Likarolo tsa mantlha tsa lathe ea CNC li kenyelletsa sesebelisoa sa mosebetsi, sesebelisoa sa ho itšeha, le molaoli oa CNC. Molaoli oa CNC o toloka faele e entsoeng ka k'homphieutha (hangata ho software ea CAD / CAM) mme o tataisa sesebelisoa sa ho itšeha ho tlosa thepa ho tloha mosebetsing ka ho nepahala le ho nepahala.Mathata ho Phokotso ea Litšenyehelo tsa CNC Lathing

Ho fokotsa litšenyehelo tsa tlhahiso ho CNC lathing e ka ba mosebetsi o rarahaneng, kaha o kenyelletsa ho ntlafatsa likarolo tse fapaneng tsa ts'ebetso. A mang a mathata a bohlokoa a kenyelletsa:- Litšenyehelo tsa Lintho: Khetho ea thepa bakeng sa workpiece e ka ama haholo litšenyehelo tsa tlhahiso. Lisebelisoa tsa boleng bo holimo le tse sa tloaelehang li ka bitsa chelete e ngata, kahoo ho bohlokoa ho khetha thepa e nepahetseng.

- Litšenyehelo tsa Lisebelisoa: CNC lathing e hloka lisebelisoa tse khethehileng tsa ho itšeha, 'me ho roala lisebelisoa le ho nkela sebaka ho ka eketsa litšenyehelo tsa tlhahiso.

- Litšenyehelo tsa Basebetsi: Basebetsi ba nang le litsebo ba hlokoa hore ba hlophise le ho sebelisa lisebelisoa tsa CNC, 'me meputso ea bona e kenya letsoho litšenyehelong tsa tlhahiso.

- Tšebeliso ea Matla: Litšepe tsa CNC li sebelisa matla bakeng sa lisebelisoa tsa mochini le tse futhumatsang, e ka bang litšenyehelo tse ngata.

- Taolo ea Litšila: Ho senyeha ha thepa ka lebaka la ho seha ho sa sebetseng hantle kapa ho hlophisa mananeo ho ka eketsa litšenyehelo le ho lematsa boiteko ba ts'ebetso.

- Nako ea ho phomola: Nako e sa reroang, tlhokomelo, le liphetoho tsa lisebelisoa li ka senya linako tsa tlhahiso le ho eketsa litšenyehelo ka kakaretso.

- Taolo ea Boleng: Ho netefatsa boleng ba likarolo tse entsoeng ka mochini ho bohlokoa, kaha likarolo tse nang le sekoli li ka lebisa ho rekoang kapa ho lahloa ho theko e boima.

Khetho ea Lintho le ho Ntlafatsa

Khetho ea thepa e ama haholo litšenyehelo tsa tlhahiso. Nahana ka maqheka a latelang:- a. Khetho ea Lintho: Lekola ts'ebeliso le litlhoko tsa karolo ho khetha thepa e baballang haholo e fihlelang litekanyetso tsa ts'ebetso.

- b. Ntlafatso ea Boitsebiso: Fokotsa litšila ka ho sebelisa boholo bo nepahetseng ba stock le libopeho ho fokotsa litšenyehelo tsa thepa le nako ea ho sebetsa.

Tooling Strategies

Ho ntlafatsa lisebelisoa ho bohlokoa bakeng sa ho fokotsa litšenyehelo. Mokhoa ona ke ona:- a. Khetho ea Lisebelisoa: Khetha e nepahetseng cnc itšeha lisebelisoa tse ipapisitseng le litlhoko tsa thepa le mochini ho ntlafatsa bophelo ba lisebelisoa le ho fokotsa litšenyehelo tsa ho nchafatsa.

- b. Tool Life Management: Kenya ts'ebetsong lits'ebetso tsa ho lekola bophelo ba lisebelisoa ho khutlisa lisebelisoa feela ha ho hlokahala, ho fokotsa litšenyehelo tsa nako le lisebelisoa.

- c. Lebelo la ho Seha le Litheko tsa Lijo: Eketsa lebelo la ho itšeha le litefiso tsa phepo bakeng sa ts'ebetso ntle le ho senya boleng ho fokotsa ho roala ha lisebelisoa.

Katleho ea Mosebetsi

Ntlafatsa katleho ea basebetsi ba hau:- a. Koetliso: Tsetela ho mananeo a koetliso ea basebetsi ho ntlafatsa litsebo, ho fokotsa liphoso le ho ntlafatsa tlhahiso.

- b. Katleho ea Lenaneo: Ntlafatsa mananeo a CNC ho fokotsa linako tsa potoloho le ho fokotsa ho kenella ha opareitara.

Tsamaiso ea Matla

Fokotsa tšebeliso ea matla ho CNC lathing:- a. Mechini e Sebetsang: Tsetela ho li-lathe tsa CNC tse bolokang matla le lits'ebetso tse pholisang ho theola litšenyehelo tsa motlakase.

- b. Production Off-Peak Production: Rulahanya machining a boima nakong ea lihora tse sehlohlolong ha litefiso tsa matla li le tlase.

Phokotso ea litšila

Fokotsa litšila le ho ntlafatsa ts'ebetso:- a. CAD/CAM Software: Sebelisa software e tsoetseng pele ho ntlafatsa litsela tsa lithulusi, ho fokotsa tšenyo ea thepa.

- b. Recycling: Kenya ts'ebetsong mananeo a ho recycle a thepa le maro a sehang ho fokotsa litšenyehelo tsa ho lahla litšila.

Tsamaiso ea nako ea ho phomola

Fokotsa nako e sa reroang:- a. Tlhokomelo e Thibelang: Kenya ts'ebetsong kemiso ea kamehla ea tlhokomelo ho thibela ho senyeha le ho boloka mochini o sebetsang hantle.

- b. Spare Parts Inventory: Boloka lethathamo le nang le thepa e ngata ea lisebelisoa tsa bohlokoa ho fokotsa nako ea ho leta bakeng sa tse ling.

Control Quality

Netefatsa likarolo tsa boleng bo holimo ho tloha qalong:- a. Tlhahlobo ea Ts'ebetso: Kenya ts'ebetsong tlhahlobo ea boleng ba nako ea 'nete ho tseba mathata esale pele le ho qoba ho sebetsa hape ho bitsang chelete e ngata.

- b. Statistical Process Control (SPC): Sebelisa mekhoa ea SPC ho beha leihlo le ho laola ts'ebetso ea machining bakeng sa boleng bo tsitsitseng.

Boiketsetso le liroboto

Kopanya othomathike ho CNC lathing process:- a. Robotic Loading: Sebelisa liroboto bakeng sa ho sebetsana le thepa le liphetoho tsa lisebelisoa ho fokotsa litšenyehelo tsa basebetsi le ho ntlafatsa ts'ebetso.

- b. Lights-Out Machining: Lekola likhetho tsa mochini oa mabone ho eketsa lihora tsa tlhahiso ntle le ho eketsa litšenyehelo tsa basebetsi.

Phepelo ea Phatlalatso

Nolofatsa mokhoa oa hau oa phepelo bakeng sa ho boloka litšenyehelo:- a. Likamano tsa barekisi: Theha likamano tse matla le barekisi ba thepa le lisebelisoa ho buisana ka lipehelo tse ntle le litheko.

- b. Feela-in-Time (JIT): Kenya ts'ebetsong tsamaiso ea thepa ea JIT ho fokotsa litšenyehelo tsa ho jara le ho fokotsa litšila.

Ntlafatso e tsitsitseng

Kholisa moetlo oa ntlafatso e tsoelang pele:- a. Lean Manufacturing: Kenya ts'ebetsong melaoana ea ho felisa litšila, ho ntlafatsa lits'ebetso, le ho fokotsa litšenyehelo ka mokhoa o hlophisitsoeng.

- b. Liketsahalo tsa Kaizen: Etsa liketsahalo tsa Kaizen ho kenyelletsa basebetsi ho tseba le ho kenya ts'ebetsong ntlafatso ea ho boloka litšenyehelo.

fihlela qeto e

Ho fokotsa litšenyehelo tsa tlhahiso nakong ea CNC lathing ke boiteko bo bongata bo hlokang mokhoa o akaretsang. Ka ho hlahloba ka hloko khetho ea thepa, maano a lisebelisoa, katleho ea basebetsi, taolo ea matla, phokotso ea litšila, taolo ea nako ea ho theoha, taolo ea boleng, boiketsetso, ntlafatso ea phepelo ea thepa, le ntlafatso e tsoelang pele, likhoebo li ka fokotsa litšenyehelo tsa tlhahiso haholo ha li ntse li boloka kapa li ntse li ntlafatsa boleng ba sehlahisoa. Ho kenya ts'ebetsong maano ana ho hloka boitlamo ba tlhahlobo e tsoelang pele le ho ikamahanya le maemo, empa melemo ea nako e telele mabapi le ho boloka litšenyehelo le tlhōlisano ke ea bohlokoa haholo.

Services Our

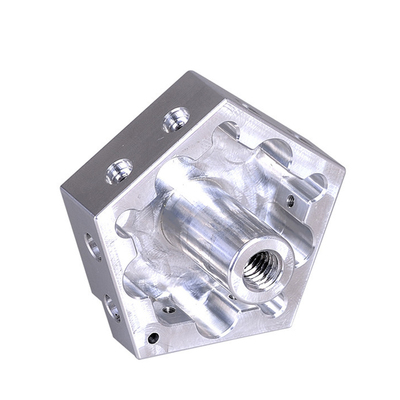

- 5 selekane Machining

- Cnc siloa

- Cnc fetola

- Mechini ea Machining

- Ts'ebetso ea Machining

- Phekolo ea bokaholimo

- Metal Machining

- Machining ea polasetiki

- Phofo Metallurgy hlobo

- Ho Casting

- Likarolo tsa Gallery

Case Studies

- Likarolo tsa Auto Metal

- Likarolo tsa mechine

- Sesebelisoa sa mocheso oa LED

- Likarolo tsa Kaho

- Likarolo tsa mobile

- Likarolo tsa Bongaka

- Likarolo tsa Elektroniki

- Machining e etselitsoeng

- Likarolo Tsa Baesekele

Lethathamo la lintho tse bonahalang

- Aluminium Machining

- Thaethaniamo Machining

- Lisebelisoa tsa Stainless Steel

- Koporo Machining

- Koporo Machining

- Super motsoako Machining

- Peek Machining

- Machining a UHMW

- Tlanya Machining

- Machining a PA6

- PPS Machining

- Mochini oa Teflon

- Inconel Machining

- Sesebelisoa sa Sesebelisoa sa Steel

- Boitsebiso bo Eketsehileng

Likarolo tsa Gallery