Ho Fuputsa Litsela tsa Mofuta oa Switzerland: Mechini, Ts'ebetso, le Likopo

2023-10-23

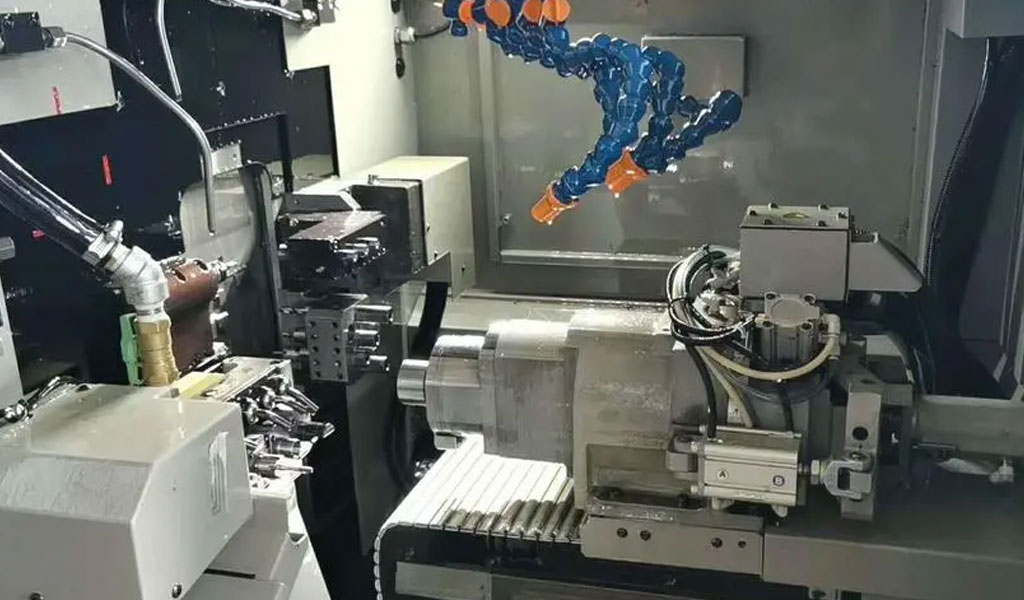

Li-Lathes tsa mofuta oa Switzerland, tse tsejoang hape e le li-lathes tsa mofuta oa Switzerland kapa mochini oa screw oa Switzerland, ke lisebelisoa tse ikhethang tse entsoeng ka boenjiniere tse nang le karolo ea bohlokoa liindastering tse fapaneng, ho kenyeletsoa sefofane, bongaka le likoloi. Sengoliloeng sena se felletseng, re tla kenella ka botebo lefats'eng la Li-Lathes tsa Mofuta oa Switzerland, re manolle mekhoa ea bona e rarahaneng le ho fana ka leseli mabapi le hore na li sebetsa joang. Hape re tla hlahloba lisebelisoa tsa bona, melemo, le theknoloji e ntseng e tsoela pele.

Karolo ea 1: Genese ea Li-Lathes tsa Mofuta oa Switzerland

1.1. Metso ea Histori

Nalane ea Switzerland Type Lathes e ka saloa morao ho tloha qalong ea lekholo la bo19 la lilemo ha sebetsa ka ho nepahetseng machining e ile ea qala ho phetha karolo ea bohlokoa indastering ea ho etsa lioache ea Switzerland. Switzerland, e neng e tumme ka boqapi ba eona ba lintho tse tšosang, e ne e hloka mokhoa oa ho hlahisa likarolo tse rarahaneng tsa oache ka mokhoa o nepahetseng ka ho fetisisa. Tlhokahalo ena ea sebetsa ka ho nepahetseng machining lisebelisoa li ile tsa rala motheo oa seo qetellong se neng se tla fetoha Li-Lathes tsa Mofuta oa Switzerland. Mathoasong a lekholo la bo19 la lilemo, indasteri ea ho etsa lioache ea Switzerland e ne e sebelisa lilathe tse tloaelehileng. Leha ho le joalo, lilathe tsena li ne li sa tšoanelehe hantle bakeng sa litlhoko tse boima tsa ho etsoa ha lioache, e leng ho neng ho hloka hore ho etsoe likaroloana tse nyenyane, tse rarahaneng le tse nepahetseng haholo. Baetsi ba litebele ba ne ba tobane le phephetso: ba ne ba hloka mokhoa oa ho fetola le ho sila likaroloana tse nyane ka nepo e ikhethang. Nako ea katleho e ile ea tla ha moetsi oa lioache oa Switzerland ea bitsoang Breguet a qapa mokhoa oa ho phonyoha lehare ka 1795. Boqapi bona bo ne bo hloka likarolo tse nepahetseng haholo, e leng se ileng sa etsa hore ho hlokahale mekhoa e tsoetseng pele ea ho etsa mechine. E le karabelo, baetsi ba lioache ba Switzerland ba ile ba qala ho etsa liteko ka meralo le liphetoho tse fapaneng tsa lathe ho fihlela se nepahetseng se hlokahalang. Khopolo ea hlooho ea hlooho e thellang, e ileng ea lumella ho laola le ho nepahala ho hoholo ha ho sebetsa li-workpieces tse nyenyane, e ile ea qala ho hlaha. Baetsi ba lioache ba Switzerland, ba kang Patek Philippe le Longines, ba phethile karolo ea bohlokoa ho ntlafatseng meralo ena ea pele. Bohareng ba lekholo la bo19 la lilemo, mosebetsi oa ho etsa lioache oa Switzerland o ne o se o tsebahala lefatšeng ka bophara bakeng sa ho nepahala ha oona, ’me liphetoho tsena tsa pele tsa lilathe e ne e le tsa bohlokoa katlehong eo.1.2. Evolution ea Swiss Lathe Technology

Phetoho ea theknoloji ea Swiss Lathe e tšoailoe ke letoto la tsoelopele ea bohlokoa ea theknoloji e ntseng e tsoela pele ho sutumelletsa meeli ea ho sebetsa ka nepo. Lintlafatso tsena ha lia ka tsa theha feela nts'etsopele ea Li-Lathes tsa Mofuta oa Switzerland empa li bile le tšusumetso lefapheng le pharaletseng la boenjiniere bo nepahetseng. Mona ke tse ling tsa liketsahalo tsa bohlokoa kholong ea theknoloji ea Swiss Lathe: 1.2.1. Tsoalo ea Mochini oa Screw oa Tornos (1880s):- Lilemong tsa bo-1880 ho bile le nts'etsopele ea Mochini oa Tornos Screw, e leng mohato oa bohlokoa ho nts'etsopele ea theknoloji ea Swiss Lathe.

- Mochine ona o ne o e-na le khoele ea othomathike 'me o khona ho hlahisa likarolo tse rarahaneng tse kholehileng ka mokhoa o nepahetseng ka tsela e hlollang.

- Mathoasong a lekholo la bo20 la lilemo, kenyelletso ea tataiso Bushing e ne e le phetoho-papali theknoloji ea Swiss Lathe.

- The guide bushing, e behiloe haufi le lisebelisoa tsa ho itšeha, e fane ka tšehetso e ke keng ea lekanngoa le botsitso ho li-workpieces tse telele, tse tšesaane, tse nolofalletsang ho sebetsa ka mokhoa o nepahetseng.

- Lilemo tsa bo-1970 li ile tsa tlisa kopanyo ea theknoloji ea Computer Numerical Control (CNC) ho Swiss Type Lathes.

- Litaolo tsa CNC li lumelletse ts'ebetso ea machining e nepahetseng le e hlophisehileng, e eketsang ho feto-fetoha ha lisebelisoa tsena.

- Tsoelo-pele ea theknoloji ea lisebelisoa le lisebelisoa li bile le karolo ea bohlokoa ho ntlafatseng ts'ebetso ea Li-Lathes tsa Mofuta oa Switzerland.

- Lisebelisoa tsa carbide, lisebelisoa tse fetohang kapele, le lijeometri tse ncha li kentse letsoho ntlafatsong. Mochini oa swiss cnc Bokhoni.

- Lilemong tse mashome tsa morao tjena, li-guide bushingless Swiss Type Lathes li se li tumme.

- Mechini ena, e nang le litšila tse fokotsehileng tsa thepa le ho eketseha ha maemo a fapaneng, e emela ho tlola ho hoholo hoa theknoloji ea Swiss Lathe.

- Bokhoni ba ho fihlella lebelo le phahameng haholo la li-spindle e fetohile lets'oao la mefuta ea sejoale-joale ea mofuta oa Switzerland.

- Ho sebetsa ka lebelo le phahameng ho lumella tlhahiso e potlakileng le ho qeta holimo holimo.

Karolo ea 2: Mechanics ea Li-Lathe tsa Mofuta oa Switzerland

2.1. Likaroloana tsa Sebopeho

Li-Lathe tsa Mofuta oa Switzerland li tsebahala ka meaho ea tsona e rarahaneng empa e sebetsa hantle haholo. Ha re hlahlobeng ka botebo likarolo tse kholo tsa meralo le mesebetsi ea tsona ho ts'ebetso ea machining: 2.1.1. Headstock:- The headstock ke karolo ea bohlokoa e ka pele ho Swiss Type Lathe.

- Morero: E boloka mokokotlo o moholo, o potolohang mosebetsi. The spindle e tsamaisoa ke motlakase oa lathe 'me e fana ka motsamao oa ho potoloha o hlokahalang bakeng sa ho sebetsa.

- Mosebetsi: Hlooho ea hlooho e netefatsa ho nepahala ha spindle, ho tsepamisa maikutlo le ho tiea, tse bohlokoa bakeng sa machining a nepahetseng.

- The guide bushing ke karolo e kang ea tube e pota-potileng mosebetsi o potolohang.

- Morero: E fana ka ts'ehetso le botsitso ho sesebelisoa sa mosebetsi, ho fokotsa ho thothomela le ho nolofalletsa machining a nepahetseng.

- Mosebetsi: The guide bushing e tšoara workpiece ka tieo sebakeng sa eona ha e ntse e lumella feela bolelele bo hlokahalang hore bo fetele ka nģ'ane ho eona, ho fokotsa ho fetoha le ho etsa bonnete ba ho sebetsa ka mokhoa o nepahetseng.

- Sesebelisoa se seholo sa lisebelisoa se behiloe haufi le bushing ea tataiso.

- Morero: E na le sesebelisoa sa mantlha sa ho itšeha se sebelisetsoang ho etsa mochini oa mosebetsi.

- Mosebetsi: Sesebelisoa se seholo sa lisebelisoa se fana ka sethala se tsitsitseng bakeng sa sesebelisoa sa ho itšeha, ho netefatsa ho nepahala ha ho itšeha.

- Li-Lathes tsa Mofuta oa Switzerland li na le sub-spindle e ka morao ho mochini.

- Morero: Sub-spindle e sebetsa e le spindle ea bobeli e ka tšoarang le ho kenya mochini oa mosebetsi ho tloha pheletsong e fapaneng.

- Mosebetsi: E nolofalletsa ho phethoa ha likarolo tse rarahaneng ka ho lumella machining lintlheng tse peli tsa workpiece ka seta e le 'ngoe.

- Li-Lathes tsa Mofuta oa Switzerland li ka kenyelletsa batho ba ts'oereng lithulusi tse phelang, tseo hangata li fumanehang holim'a mochini oa li-gang slide kapa turret.

- Morero: Basebelisi ba lisebelisoa tse phelang ba lumella hore ho be le ts'ebetso ea bobeli ea machining, joalo ka ho phunya le ho sila, ho etsoa holim'a sesebelisoa ntle le ho e tlosa mochining.

- Mosebetsi: Lits'oants'o tsena tsa lisebelisoa li ntlafatsa bokhoni ba lathe le ho fokotsa tlhoko ea lisebelisoa tse eketsehileng tsa mochini.

- Sehloho se thellang ke kopano e suthang e ka thellang haufi le bethe ea lathe.

- Morero: Mosebetsi oa eona o ka sehloohong ke ho etsa hore machining a nepahale le a hokahaneng a li-workpieces tse telele, tse tšesaane.

- Sehlooho se thellang se tiisa ho nepahala ho ikhethang ka ho lumella workpiece ho tšehetsoa haufi le sesebelisoa sa ho itšeha.

- Karolo: Bohaufi bona bo fokotsa ho kheloha, ho thothomela le liphoso, ho fella ka ho nepahala le ho fella ka bokaholimo.

- Lisebelisoa tse telele le tse tšesaane, tse atisang ho phephetsa mochine ka li-lathes tse tloaelehileng, li sebetsoa ka katleho ho sebelisa lihlooho tse thellang.

- Mosebetsi: Sehlooho se thellang se thusa ho sebetsa ka mokhoa o tsoelang pele ntle le tlhokahalo ea ho behoa khafetsa, ho fokotsa linako tsa potoloho le ho netefatsa hore karolo e lumellana.

- Li-Lathes tsa Mofuta oa Switzerland li sebelisa mefuta e fapaneng ea lithulusi, ho kenyeletsoa ba nang le lisebelisoa tse tsitsitseng le tse phelang.

- Bohlokoa: Ba nang le lisebelisoa ba boloka lisebelisoa tsa ho seha li le teng 'me ba etsa bonnete ba hore ba lumellana hantle le mosebetsi.

- Ho nepahala: Ho tiea le botsitso ba lisebelisuoa ke tsa bohlokoa bakeng sa ho fumana mekhoa e nepahetseng le ho boloka mamello e itseng.

- Geometry ea lisebelisoa, joalo ka li-angles tsa rake le li-angles tsa clearance, li tlameha ho khethoa ka hloko ho latela litlhoko tse khethehileng tsa mochini.

- Bohlokoa: Geometry ea sesebelisoa e nepahetseng e fokotsa matla a ho itšeha, e fokotsa ho roala ha lisebelisoa, 'me e ntlafatsa boleng ba bokaholimo.

- Khetho ea Boitsebiso: Lisebelisoa tsa lisebelisoa, tse kang carbide kapa tšepe e phahameng ka potlako, li ama bophelo ba lisebelisoa le ts'ebetso ea ho itšeha, e leng se etsang hore e be taba ea bohlokoa.

Karolo ea 3: Kamoo Li-Lathe tsa Mofuta oa Switzerland li Sebetsang Kateng

3.1. Mokhoa oa ho Fepa Lintho Tse Bonahalang

Mochini oa phepelo ea lintho tse bonahalang ho Swiss Type Lathes ke karolo ea bohlokoa e lumellang lisebelisoa tse telele, tse tšesaane hore li jarolloe le ho etsoa ka mochini. E sebetsa tjena: Material Loading:- Litšepe tse telele, tse otlolohileng tsa thepa e tala, tseo hangata li entsoeng ka litšepe tse kang tšepe e sa hloekang kapa aluminiamo, li kenngoa ka har'a mochini o fepelang oa lathe.

- Sesebelisoa sa bar se tšoara le ho ntšetsa pele lisebelisoa ka har'a mochini.

- Ha thepa e kena mochine, e feta ka har'a bushing ea tataiso, e behiloeng haufi haholo le lisebelisoa tsa ho itšeha.

- The guide bushing e fana ka ts'ehetso le tataiso ea bohlokoa ho thepa, ho netefatsa hore e lula e tsitsitse ebile e tsepamisitsoe nakong ea machining.

- Thepa e tsoetse pele ka bushing ea tataiso ha ts'ebetso ea machining e ntse e tsoela pele, e lumellang ho sebetsa ka mokhoa o nepahetseng le o tsoelang pele.

- Bukana ea tataiso e fokotsa ho thothomela le ho kheloha ha thepa, e leng ntho ea bohlokoa haholo ha ho etsoa lisebelisoa tse telele le tse tšesaane.

- E kenya letsoho ho nepahala ho ikhethang hoo Li-Lathe tsa Mofuta oa Switzerland li tsejoang ka tsona.

3.2. Precision Machining

Ho sebetsa ka mokhoa o nepahetseng ho mofuta oa Switzerland oa Lathe ho kenyelletsa letoto la mehato e hokahaneng hantle e reretsoeng ho fihlela ho nepahala ho ikhethang le pheletso ea bokaholimo: Mohato oa 1: Tokisetso ea Lintho.- Thepa e tala e kenngoa ka har'a bar feeder, 'me bolelele ba eona boa fetoloa ho netefatsa hore e fetela ka nģ'ane ho sehlahla sa tataiso.

- Sebaka sa ho sebetsa se pota-potiloe ke mokokotlo o moholo ha lisebelisoa tsa ho seha, tse behiloeng holim'a lisebelisoa, li sebelisana le thepa.

- Mesebetsi ea ho seha e ka kenyelletsa ho reteleha, ho thaepa, ho grooving, ho cheka le ho sila, ho itšetlehile ka sebopeho sa karolo le litlhaloso.

- Lebelo le phahameng la spindle ke lets'oao la Li-Swiss Type Lathes. Li lumella hore ho be le litekanyetso tse potlakileng tsa ho tlosoa ha thepa le ho qeta holimo holimo.

- Ho kopanngoa ha lebelo le phahameng la spindle le tšehetso ea bushing ea tataiso ho fokotsa matla le ho thothomela, ho ntlafatsa ho nepahala.

- Li-Lathes tsa Mofuta oa Switzerland hangata li na le litsamaiso tsa phetoho tse potlakileng tsa lisebelisoa, tse lumellang ho fetoha ha lisebelisoa ka potlako nakong ea mochini.

- Liphetoho tse potlakileng tsa lisebelisoa li fokotsa nako ea ho theoha le ho eketsa tlhahiso, e leng ho nolofalletsang hore ho etsoe mesebetsi e fapaneng ka mokhoa o le mong.

- Li-Lathes tsa Mofuta oa Switzerland li ipabola ho etseng mesebetsi e mengata ea machining ka nako e le 'ngoe.

- Le hoja spindle e ka sehloohong e sebetsa karolong e 'ngoe ea mosebetsi, ba nang le lisebelisoa ba phela ba ka etsa mesebetsi ea bobeli, e kang ho cheka kapa ho sila, ka lehlakoreng le leng.

- Li-Lathes tsa Mofuta oa Switzerland li na le "sub-spindle" tse lumellang machining lintlheng tse peli tsa sesebelisoa ka seta se le seng.

- Bokhoni bona bo bohlokoa haholo bakeng sa likarolo tse rarahaneng tse hlokang machining mahlakoreng ka bobeli.

3.3. Lenaneo la Swiss Lathe

Lenaneo la Swiss Lathe le kenyelletsa tšebeliso ea litsamaiso tsa Computer Numerical Control (CNC) ho laola metsamao le ts'ebetso ea lathe. Mona ke lintlha tsa bohlokoa tsa lenaneo la Swiss Lathe: Litaolo tsa CNC:- Li-Lathes tsa Mofuta oa Switzerland li na le li-control tse tsoetseng pele tsa CNC tse lumellang basebelisi ho hlophisa le ho laola ts'ebetso ea mochini.

- Litaolo tsa CNC li fana ka sebopeho se bonolo sa mosebelisi bakeng sa ho kenya lintlha tsa likarolo le litselana tsa lisebelisoa.

- Ts'ebetso ea ho hlophisa hangata e kenyelletsa ho hlahisa likhoutu tsa G, e leng litaelo tsa alphanumeric tse laolang motsamao oa sesebelisoa le ts'ebetso ea cnc machining.

- Likhoutu tsa G li hlahisoa ho ipapisitsoe le moralo oa karolo le ts'ebetso e lakatsehang ea machining.

- Ho reteleha: G00 (maemo a potlakileng), G01 (phetolelo ea mola), G02/G03 (ho kenyeletsoa ka selikalikoe).

- Khoele: G76 (threading cycle).

- Ho cheka: G81 (potoloho ea ho phunya).

- Ho sila: G12/G13 (ho sila pokotho e chitja).

- Boemo ba C-axis: G01 e nang le motsamao oa C-axis.

- Pele mosebetsi oa 'nete o qala, basebelisi ba atisa ho etsa lipapiso ho netefatsa ho nepahala ha lenaneo le ho netefatsa hore litsela tsa lisebelisoa ha li na ho thulana.

3.4. Pholiso le Tsamaiso ea Chip

Tsamaiso ea ho pholisa le ea chip ke lintlha tsa bohlokoa ts'ebetsong ea mofuta oa Swiss Type Lathe: Coolant Systems:- Li-Lathes tsa Mofuta oa Switzerland li na le lisebelisoa tse pholileng tse tsamaisang metsi a sehang sebakeng sa ho itšeha.

- Bohlokoa: Sepholi se sebetsa merero e mengata, ho kenyelletsa ho ntša mocheso, ho tlotsa sesebelisoa, le ho ntša lichipisi.

- Pholiso e nepahetseng e thusa ho boloka mocheso oa lisebelisoa le lisebelisoa tsa mosebetsi, ho thibela mocheso o feteletseng le ho roala ha lisebelisoa.

- Ha lisebelisoa tsa ho itšeha li tlosa thepa, li-chips lia hlahisoa 'me li hloka ho laoloa hantle.

- Li-conveyors kapa li-chip augers li bokella le ho tlosa li-chips sebakeng sa mochini.

- Taolo e sebetsang ea chip e bohlokoa bakeng sa mochini o sa sitisoeng le ho boloka tikoloho e hloekileng ea mosebetsi.

Karolo ea 4: Likopo le Liindasteri

Li-Swiss Type Lathes li fumane lits'ebetso tse atileng liindastering tse fapaneng ka lebaka la ts'ebetso le ts'ebetso ea tsona e ke keng ea lekanngoa. Ha re hlahlobeng karolo ea bona ea bohlokoa tlhahisong ea sepakapaka, tlhahiso ea lisebelisoa tsa bongaka, lefapha la likoloi, le lisebelisoa tsa elektroniki le microtechnology.4.1. Tlhahiso ea Sepakapaka

Indasteri ea sepakapaka e hloka likarolo tse nepahetseng haholo le tse tšepahalang. Li-Lathe tsa Mofuta oa Switzerland li bohlokoa haholo bakeng sa ho hlahisa likarolo tsa bohlokoa tsa sepakapaka joalo ka mahare a turbine, fasteners, le tse ling. Lisebelisoa tsa turbine:- Li-Lathes tsa Mofuta oa Switzerland li sebelisoa ho etsa li-blade tsa turbine tsa mochini tse nang le lintlha tse rarahaneng tsa foil ea moea.

- Li-blade tsena li bohlokoa bakeng sa lifofane le li-turbine tse fehlang motlakase, moo ho nepahala ho leng bohlokoa haholo bakeng sa ts'ebetso le ts'ebetso e nepahetseng.

- Li-lathe tsa Switzerland li netefatsa mamello e tiileng le ho qeta holimo holimo, ho ntlafatsa ts'ebetso ea turbine.

- Li-fasteners tsa sefofane, ho kenyeletsoa liboutu le likurufu, li hloka machining a nepahetseng ho netefatsa likhokahano tse sireletsehileng le tse tšepahalang.

- Li-Lathes tsa Mofuta oa Switzerland li ipabola ho hlahiseng likarolo tsena ka botsitso le ka nepo.

- Lebelo le ho nepahala ha li-lathe tsena li kenya letsoho tlhahisong e ntle ea tlhahiso ea li-fasteners tsa aerospace.

4.2. Tlhahiso ea Sesebelisoa sa Bongaka

Swiss Type Lathes e bapala karolo ea bohlokoa indastering ea bongaka ka ho etsa li-implants, lisebelisoa tsa ho buoa, likarolo tsa meno le tse ling. Li-implants:- Li-implants tsa masapo le tsa meno, tse kang li-prostheses tsa noka le li-screw tsa meno, li hloka ho nepahala le ho lumellana le bophelo.

- Li-Lathes tsa Mofuta oa Switzerland li sebelisoa ho kenya likarolo tsena ho tloha ho thepa e kang titanium le tšepe e sa hloekang ho ea ka litlhaloso tse hlakileng.

- Ho nepahala ha li-lathes tsena ho tiisa hore ho sebetsa ka mokhoa o phethahetseng le ho tšoarella nako e telele ho li-implants tsa bongaka.

- Lisebelisoa tsa ho buoa, ho kenyeletsoa scalpels le forceps, li tlameha ho etsoa ka bokhabane bakeng sa ho nepahala le ho sebelisoa habonolo.

- Li-Lathes tsa Mofuta oa Switzerland li sebelisoa ho hlahisa lisebelisoa tsena ka mokhoa o nepahetseng le o tsitsitseng.

- Boleng le ho tšepahala ha lisebelisoa tsa ho buoa tse entsoeng ka li-lathe tsa Switzerland li bohlokoa lefapheng la bongaka.

4.3. Lefapha la Likoloi

Indasteri ea likoloi e itšetlehile ka Li-Lathe tsa Mofuta oa Switzerland bakeng sa tlhahiso ea likarolo tsa bohlokoa, ho kenyelletsa le liente tsa mafura, thekos, le li-connectors. Liente tsa Mafura:- Liente tsa mafura ke likarolo tsa bohlokoa tsa koloi tse hlokang ho nepahala ho phahameng bakeng sa phano e nepahetseng ea mafura.

- Li-Lathes tsa Mofuta oa Switzerland li sebelisoa ho etsa likarolo tsa mochini oa ente, ho netefatsa mamello e tiileng bakeng sa ts'ebetso e nepahetseng ea enjene le taolo ea mesi.

- Li-shafts tse nepahetseng li sebelisoa lits'ebetsong tse fapaneng tsa likoloi, ho kenyelletsa le li-transmission le li-drivetrains.

- Li-Lathes tsa Mofuta oa Switzerland li sebelisoa ho hlahisa li-shafts tsena ka ho nepahala le ho qeta holimo ho hlokahalang bakeng sa ts'ebetso e bonolo.

- Lihokelo tsa likoloi, joalo ka tse sebelisoang litsing tsa motlakase, li hloka mochini o nepahetseng bakeng sa khokahanyo e tšepahalang.

- Li-Lathes tsa Mofuta oa Switzerland li sebelisoa ho etsa likhokahano tse nang le meralo e rarahaneng le mamello e thata.

- Indasteri ea likoloi e na le liphetoho tse kholo, ho kenyelletsa le ho fetohela ho likoloi tsa motlakase le tse ikemetseng.

- Li-Lathes tsa Mofuta oa Switzerland li ikamahanya le maemo ho fihlela litlhoko tse ntseng li tsoela pele, tse kang ho lokisa likarolo tsa motlakase oa motlakase le lisebelisoa tse tsoetseng pele tsa kutlo.

4.4. Electronics le Microtechnology

Makala a lisebelisoa tsa elektroniki le theknoloji e nyenyane e rua molemo ho Li-Swiss Type Lathes, haholo-holo tlhahisong ea lihokelo tsa elektroniki tse rarahaneng le likaroloana tse nyane. Lihokelo tsa Elektronike:- Li-Lathes tsa Mofuta oa Switzerland li ipabola ho machining lihokelo tse nyane tse sebelisoang ho elektroniki le likhokahanong tsa mehala.

- Lihokelo tsena li hloka phini e nepahetseng le likaroloana tsa sokete, tse hlahisoang ka nepo ho sebelisoa li-lathe tsa Switzerland.

- Li-Lathes tsa Mofuta oa Switzerland li bohlokoa haholo bakeng sa ho qapa li-microcomponents joalo ka Lisebelisoas, li-nozzles, le likurufu tse nyane tse sebelisoang lits'ebetsong tse fapaneng tsa microtechnology.

- Ha mokhoa o lebisang ho miniaturization o ntse o tsoela pele, li-lathe tsa Switzerland li bapala karolo ea bohlokoa ho fihlela litlhoko tsa likaroloana tse nyane, tse nepahetseng haholoanyane.

- Tlhokahalo ea lisebelisoa tsa elektroniki tse nyane le tse sebetsang haholoanyane e ntse e hola.

- Li-Lathes tsa Mofuta oa Switzerland li loketse hantle ho hlahisa likaroloana tse nyane, tse nepahetseng haholo tse hlokehang bakeng sa li-smartphone, tse aparoang, le mahlale a mang a manyane.

Karolo ea 5: Melemo le Mefokolo

Li-Lathe tsa Mofuta oa Switzerland li fana ka mefuta e mengata ea melemo e etsang hore e be ea bohlokoa haholo indastering e mengata. Leha ho le joalo, li boetse li tla le mefokolo le mathata a itseng a lokelang ho nahanoa. Ha re hlahlobeng likarolo tseo ka bobeli ka botlalo:5.1. Melemo ea Li-Lathe tsa Mofuta oa Switzerland

5.1.1. Ho nepahala ho Phahameng:

Li-Lathe tsa Mofuta oa Switzerland li tumme ka ho nepahala le ho nepahala ho ikhethang. Melemo: Ho mamellana ho tiileng ho ka finyelloa ka linako tsohle, ho etsa hore e be tse loketseng liindasteri tse kang ho etsa lifofane le lisebelisoa tsa bongaka. Likarolo tse hlahisoang ka li-lathe tsa Switzerland li hloka ts'ebetso e fokolang ea morao-rao kapa ts'ebetso e eketsehileng ea ho qetela.5.1.2. Nako e Fokotseng ea Potoloho:

Li-lathe tsena li etselitsoe ho sebetsa ka lebelo le phahameng, e leng se bakang linako tse khuts'oane tsa potoloho. Melemo: Keketseho ea tlhahiso le linako tsa phetoho e potlakileng liindastering moo ho sebetsa hantle ho leng bohlokoa, joalo ka likoloi le lisebelisoa tsa elektroniki.5.1.3. Sephetho se Ikhethileng sa Bokaholimo:

Li-Swiss Type Lathes li hlahisa likarolo tse nang le lisebelisoa tse holimo ka lebaka la lebelo la tsona le holimo le ho nepahala. Melemo: Likarolo tse nang le liphetho tse ntle tsa bokaholimo li bohlokoa lits'ebetsong tse kang lisebelisoa tsa bongaka le lisebelisoa tsa elektroniki, moo botle le ts'ebetso li leng bohlokoa.5.1.4. Ts'ebetso e Tšoanang:

Li-lathe tsa Switzerland li ka etsa mesebetsi e mengata ea mochini ka nako e le 'ngoe, tsa fokotsa linako tsa ho seta. Melemo: Bokhoni bo ntlafetseng le ho baballa litšenyehelo, haholo-holo indastering e kang ea sefofane le likoloi, moo likarolo tse rarahaneng li hlokang ts'ebetso e fapaneng.5.1.5. Lisebelisoa tse telele le tse tšesaane:

Li-lathe tsena li loketse ka mokhoa o ikhethileng bakeng sa ho etsa lisebelisoa tse telele le tse tšesaane. Melemo: E loketse liindasteri tse kang sefofane, moo likaroloana tse kang mahare a turbine li hlokang ho nepahala le botsitso nakong ea ho sebetsa ka mechine.5.1.6. Ho feto-fetoha ha maemo:

Li-Lathes tsa Mofuta oa Switzerland li khona ho sebetsana le mefuta e mengata ea thepa, ho tloha ka tšepe ho ea ho li-plastiki. Melemo: Ho feto-fetoha ha maemo tabeng ea ho khetha thepa ho bohlokoa indastering e kang ea ho etsa lisebelisoa tsa bongaka le tsa elektroniki, tseo hangata li hlokang thepa e khethehileng.5.1.7. Tsamaiso e Sebetsang ea Chip:

Li-lathe tsa Switzerland li na le litsamaiso tse sebetsang tsa taolo ea li-chip. Melemo: Mechine e sa sitisoeng le nako e fokotsehileng ka lebaka la ho tlosoa ha chip ka tsela e sebetsang hantle. Kameho ho Liindasteri tse fapaneng:- Aerospace: Li-lathe tsa Switzerland li netefatsa ts'ebetso e nepahetseng ea likarolo tsa bohlokoa, ho ntlafatsa polokeho le ts'ebetso.

- Lisebelisoa tsa Bongaka: Lisebelisoa tse nepahetseng haholo le tse lumellanang le bioloji li etsa hore likhoele tsa Switzerland e be tsa bohlokoa bakeng sa ho etsa li-implants le lisebelisoa tsa bongaka.

- Likoloi: Linako tse khuts'oane tsa libaesekele le mochini o nepahetseng li kenya letsoho ho ntlafatseng ts'ebetso ea koloi le ho fokotsa litšenyehelo.

- Electronics le Microtechnology: Li-lathe tsa Switzerland li thusa ho hlahisa likarolo tse rarahaneng tsa lisebelisoa tsa elektronike tse nyenyane, tse finyellang litlhoko tsa theknoloji ea morao-rao.

5.2. Meeli le Mathata

5.2.1. Ho rarahana: Li-Lathe tsa Mofuta oa Switzerland ke mechini e rarahaneng e hlokang basebetsi ba nang le boiphihlelo le baetsi ba mananeo. Meeli: Ho qala le ho hlophisa mananeo ho ka nka nako mme ho hloka tsebo le koetliso e khethehileng. 5.2.2. Litšenyehelo: Li-lathe tsa Switzerland ke letsete le leholo, 'me litšenyehelo tsa bona tsa ho reka qalong li ka ba holimo. Meeli: Likhoebo tse nyane li ka fumana litšenyehelo tsa pele li le tlase, le hoja phaello ea katleho e atisa ho lokafatsa matsete. 5.2.3. Boholo bo fokolang ba Mosebetsi: Li-lathe tsa Switzerland li ntlafalitsoe bakeng sa ho etsa lisebelisoa tse telele le tse tšesaane. Meeli: Li kanna tsa se tšoanelehe bakeng sa likarolo tse kholoanyane kapa tse ngata, li fokotsa ts'ebeliso ea tsona liindastering tse ling. 5.2.4. Khetho ea Lintho: Le ha li-lathe tsa Switzerland li khona ho sebetsana le lisebelisoa tse fapaneng, e kanna ea se be khetho e ntle ka ho fetisisa bakeng sa thepa e thata haholo kapa e sa tloaelehang. Meeli: Liindasteri tse ling tse hlokang thepa e khethehileng li ka 'na tsa hloka ho hlahloba mekhoa e meng ea mochini. 5.2.5. Nako ea ho Seta bakeng sa Litsamaiso tse Nyenyane: Li-lathe tsa Switzerland li ipabola tlhahisong ea boleng bo holimo empa li ka ba le nako e telele ea ho seta bakeng sa tlhahiso e nyane ea tlhahiso. Meeli: Bakeng sa tlhahiso ea li-batch tse nyane, nako ea ho seta e ka fokotsa melemo ea machining a lebelo le phahameng. 5.2.6. Tool Wear: Li-lathe tsa Switzerland li sebelisa lebelo le phahameng la spindle, e leng se ka lebisang ho roaeng ha lisebelisoa. Meeli: Liphetoho tsa lisebelisoa khafetsa le tlhokomelo li ka hlokahala, tse amang ts'ebetso e akaretsang. Qetellong, Swiss Type Lathes e fana ka melemo e makatsang, ho kenyelletsa ho nepahala, lebelo le ho feto-fetoha ha maemo, e leng se etsang hore e be tsa bohlokoa liindastering tse fapaneng. Leha ho le joalo, ha li na mefokolo le liphephetso tsa tsona, tse kang ho rarahana le litšenyehelo. Ho bohlokoa ho shebisisa lintlha tsena ka hloko ha ho khethoa hore na li-lathe tsa Switzerland li nepahetse bakeng sa litlhoko tse ikhethang tsa tlhahiso.Karolo ea 6: Emerging Technologies

Li-Lathes tsa Mofuta oa Switzerland ha li sireletsehe ho tsoelopele ea theknoloji ea Indasteri ea 4.0 le lisebelisoa / lisebelisoa tsa lisebelisoa. Ha re hlahlobeng hore na li-lathe tsena li ikamahanya le maemo a ntseng a fetoha joang:6.1. Indasteri 4.0 Kopanyo

Li-Lathes tsa Mofuta oa Switzerland li ntse li kenyelletsa melao-motheo ea Industry 4.0, leveraging automation, analytics data, le khokahanyo ho ntlafatsa bokhoni ba bona: 6.1.1. Motlakase:- Ho kopanngoa le mekhoa ea liroboto ho lumella mochine oa ho tima mabone, moo li-lathe tsa Switzerland li ka sebetsang ka boithaopo 24/7.

- Melemo: Keketseho ea katleho ea tlhahiso, ho fokotsa litšenyehelo tsa basebetsi, le tšebeliso e ntlafalitsoeng ea mochini.

- Li-Lathes tsa Mofuta oa Switzerland li na le li-sensor le mekhoa ea ho bokella lintlha.

- Melemo: Ho lekola ts'ebetso ea mochini le data ea tlhahiso ka nako ea 'nete, ho lumella ho etsa liqeto ho tsamaellanang le data le ho ntlafatsa ts'ebetso.

- Tlhokomelo e Lebeletsoeng: Litlhahlobo tsa data li thusa ho bolela esale pele litlhoko tsa tlhokomelo ho latela boemo ba mochini, ho fokotsa nako e sa reroang.

- Li-lathe tsa Switzerland li ka kopanngoa le Manufacturing Execution Systems (MES) kapa Industrial Internet of Things (IIoT).

- Melemo: Puisano e se nang moeli pakeng tsa mechini le litsamaiso tsa moralo oa tlhahiso, taolo ea thepa le taolo ea boleng.

- Tlhokomelo ea Remote: Basebelisi ba ka lekola ts'ebetso ea mochini mme ba amohela litemoso ba le hole, ba ntlafatsa karabelo.

- Theknoloji ea mafahla ea dijithale e theha likopi tsa mofuta oa Swiss Type Lathes.

- Melemo: Mafahla a dijithale a lumella lipapiso tse tsoetseng pele le ho ntlafatsa, ho fokotsa linako tsa ho seta le ho fokotsa liphoso.

- Li-lathe tsa sejoale-joale tsa Switzerland li na le li-interfaces tse bonolo tsa basebelisi le li-touchscreens bakeng sa mananeo a hlakileng le ho beha leihlo.

- Melemo: boiketlo bo ntlafetseng ba ts'ebeliso le ho fokotsa linako tsa koetliso bakeng sa basebetsi.

6.2. Lisebelisoa le Lisebelisoa tsa Lisebelisoa

Tsoelo-pele ea lisebelisoa le lisebelisoa li atolosa bokhoni ba Li-Lathes tsa Mofuta oa Switzerland, ho li nolofalletsa ho sebetsa ka mefuta e mengata ea lisebelisoa le ho finyella ho nepahala ho phahameng: 6.2.1. Lisebelisoa tse tsoetseng pele:- Li-Lathes tsa Mofuta oa Switzerland joale li khona ho etsa lisebelisoa tse tsoetseng pele joalo ka li-composite, li-superalloy le lirafshoa.

- Melemo: Libaka tse atolositsoeng tsa ts'ebeliso, haholo indastering ea sefofane le theknoloji e phahameng moo lisebelisoa tsena li atileng teng.

- Mathata: Ho etsa lisebelisoa tse tsoetseng pele ho ka hloka lisebelisoa le mekhoa e khethehileng ka lebaka la thepa ea bona e ikhethang.

- Liaparo tsa lisebelisoa tse kang carbon-like carbon (DLC) le titanium nitride (TiN) li ntlafatsa bophelo ba lisebelisoa le ts'ebetso ea ho itšeha.

- Melemo: Ho sebelisoa ha lisebelisoa ho fokotsehile, bokaholimo bo ntlafalitsoeng, le nako e telele lipakeng tsa liphetoho tsa lisebelisoa.

- Li-lathe tsa Switzerland li na le lisebelisoa tse nyane tsa ho etsa lisebelisoa tse nyane, tse rarahaneng.

- Melemo: Ho nepahala ho ntlafalitsoeng bakeng sa microtechnology le lisebelisoa tsa elektroniki.

- Software e tsoetseng pele ea CAM e thusa ho hlahisa lisebelisoa tse nepahetseng bakeng sa likarolo tse rarahaneng.

- Melemo: Nako e fokotsehileng ea nako ea potoloho, sebaka se ntlafalitsoeng sa bokaholimo, le moaparo o fokolang oa lisebelisoa.

- Machining a Adaptive a sebelisa data ea nako ea nnete ho fetola maemo a ho itšeha, ho ntlafatsa ts'ebetso ea machining.

- Melemo: Ho ntlafala ho sebetsa hantle, ho fokotsa tšebeliso ea matla, le bophelo bo bolelele ba lisebelisoa.

Karolo ea 7: Qeto

7.1. Kakaretso ea Lintlha tsa Bohlokoa

Patlisisong ena e batsi ea Li-Swiss Type Lathes, re kentse lihlooho tse ngata tse fapaneng, ho kenyeletsoa tšimoloho ea tsona ea nalane, boqapi, ts'ebetso, ts'ebeliso, melemo, mefokolo, le ho hokahana ha tsona le mahlale a ntseng a hlaha. Mona ke lintlha tsa bohlokoa tseo u ka li nkang:- Metso ea Histori: Li-Lathe tsa Mofuta oa Switzerland li simolohile litlhokong tse nepahetseng tsa indasteri ea ho etsa lioache ea Switzerland ea lekholong la bo19 la lilemo, e ntse e tsoela pele ho fihlela litlhoko tsa makala a fapaneng a boleng bo holimo.

- Mechanics: Li-lathes tsena li khetholloa ka likarolo tsa moralo tse kang hlooho, li-guide bushing, le lisebelisoa tsa lisebelisoa, tse nang le mochine o thellang bakeng sa mochine o nepahetseng le o sebetsang hantle.

- ts'ebetso ea: Li-Lathes tsa Mofuta oa Switzerland li ipabola tabeng ea ho fepa thepa, ho sebetsa ka mokhoa o nepahetseng, ho etsa mananeo, ho pholisa, le tsamaiso ea chip, e leng se etsang hore e be tse loketseng liindasteri tse hlokang ho nepahala le ho sebetsa hantle haholo.

- dikopo: Li-Lathe tsa Mofuta oa Switzerland li bapala karolo ea bohlokoa sebakeng sa sefofane, tlhahisong ea lisebelisoa tsa bongaka, lekaleng la likoloi, le lisebelisoa tsa elektroniki le theknoloji e nyane, ho hlahisa likarolo tsa bohlokoa bakeng sa liindasteri tsena.

- le menyetla: Li fana ka ts'ebetso e nepahetseng e phahameng, linako tse fokotsehileng tsa potoloho, liphetho tse ikhethang tsa bokaholimo, ts'ebetso ea nako e le 'ngoe, le taolo e ntle ea chip, e amang liindasteri tse fapaneng hantle.

- Meeli le Mathata: Li-Lathes tsa Mofuta oa Switzerland li tla le mathata a kang ho rarahana, litšenyehelo, boholo bo fokolang ba mosebetsi, le ho roala lisebelisoa. Hoa hlokahala ho ela hloko ka hloko ha u li khetha bakeng sa lisebelisoa tse khethehileng.

- Theknoloji e Tsoelang Pele: Li-Lathes tsa Mofuta oa Switzerland li kenyelletsa ho kopanngoa ha Indasteri ea 4.0, ho kenyelletsa li-automation, analytics data, le khokahanyo. Lisebelisoa le lisebelisoa tsa lisebelisoa li eketsa bokhoni ba tsona, li nolofalletsa ho sebetsa ha thepa e tsoetseng pele le ho finyella ho nepahala ho phahameng.

7.2. Maikutlo a Bokamoso

Bokamoso ba Li-Lathes tsa Mofuta oa Switzerland bo shebahala bo ts'episa, bo susumetsoa ke tsoelopele e tsoelang pele ea theknoloji le litlhoko tse tsoelang pele tsa indasteri:- Industry 4.0: Ho kopanngoa ha mahlale a Indasteri 4.0 ho tla tsoela pele ho ntlafatsa katleho, tlhahiso, le karabelo ea mofuta oa Swiss Type Lathes, e leng ho etsang hore e be tsa bohlokoa le ho feta tlhahisong ea sejoale-joale.

- Tsoelo-pele ea Lintho: Ha liindasteri li batla lisebelisoa tse ncha tse nang le thepa e ikhethang, li-lathe tsa Switzerland li tla ikamahanya le mochine oa lisebelisoa tsena ka katleho, li atolose libaka tsa tsona tsa kopo.

- Tooling Innovations: Lisebelisoa li tla tsoela pele ho fetoha ka liphaephe, miniaturization, machining a ikamahanyang le maemo, le ts'ebetso e ntlafalitsoeng ea lithulusi, e ntlafatsa ho nepahala le ho sebetsa hantle.

- Mokhoa oa Miniaturization: Ha liindasteri li ntse li hatela pele molemong oa ntlafatso e nyane, Swiss Type Lathes e tla bapala karolo ea bohlokoa ho rapeng likarolo tse rarahaneng tsa lisebelisoa tsa elektroniki, lisebelisoa tsa bongaka le theknoloji e nyane.

- itsetsepetse: Khatello ea ts'ebetso ea ts'ebetso ea tlhahiso e tla khanna lisebelisoa tsa Switzerland ho sebelisa mekhoa e metle ea tikoloho le ho fokotsa tšebeliso ea matla.

Services Our

- 5 selekane Machining

- Cnc siloa

- Cnc fetola

- Mechini ea Machining

- Ts'ebetso ea Machining

- Phekolo ea bokaholimo

- Metal Machining

- Machining ea polasetiki

- Phofo Metallurgy hlobo

- Ho Casting

- Likarolo tsa Gallery

Case Studies

- Likarolo tsa Auto Metal

- Likarolo tsa mechine

- Sesebelisoa sa mocheso oa LED

- Likarolo tsa Kaho

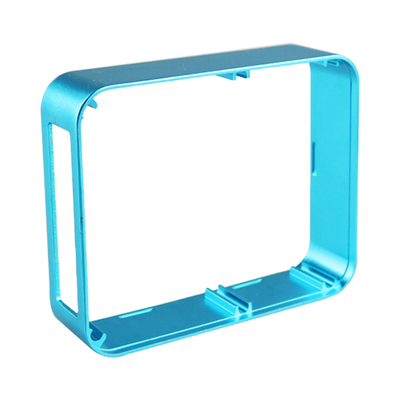

- Likarolo tsa mobile

- Likarolo tsa Bongaka

- Likarolo tsa Elektroniki

- Machining e etselitsoeng

- Likarolo Tsa Baesekele

Lethathamo la lintho tse bonahalang

- Aluminium Machining

- Thaethaniamo Machining

- Lisebelisoa tsa Stainless Steel

- Koporo Machining

- Koporo Machining

- Super motsoako Machining

- Peek Machining

- Machining a UHMW

- Tlanya Machining

- Machining a PA6

- PPS Machining

- Mochini oa Teflon

- Inconel Machining

- Sesebelisoa sa Sesebelisoa sa Steel

- Boitsebiso bo Eketsehileng

Likarolo tsa Gallery