Mokhoa oa ho bokana le ho kenya lisebelisoa tsa mochini oa CNC Mokhoa o nepahetseng le malebela a matle

2023-10-30

Khaolo ea 1: Ho utloisisa Mechini ea CNC

Khaolong ena, re tla rala motheo ka ho hlahloba hore na mechine ea CNC ke efe, mefuta e sa tšoaneng e fumanehang, le likarolo tsa bohlokoa tse etsang mochine oa CNC.a. Mochini oa CNC ke eng?

Mochini oa CNC, o khuts'oane bakeng sa mochini oa Computer Numerical Control, ke sesebelisoa se tsoetseng pele se sebelisoang ho etsa le ts'ebetso ea machininges. Ho fapana le mechini e tloaelehileng e sebelisoang ka letsoho ke basebelisi ba batho, mechini ea CNC e itirile ebile e laoloa ke likhomphutha, e lumellang ts'ebetso e nepahetseng le e pheta-phetoang haholo. Mechini ena e khona ho etsa mesebetsi e rarahaneng e kang ho seha, ho cheka, ho sila le ho etsa lintho tse kang tšepe, polasetiki, lehong le tse ling. Bohareng ba mochini oa CNC ke bokhoni ba ona ba ho toloka le ho phethahatsa litaelo tse tsoang ho moralo o thusoang ke khomphutha (CAD) kapa software ea komporo e thusang (CAM). Software ena e hlahisa letoto la li-code tsa linomoro, tseo hangata li bitsoang G-codes le M-codes, tse laelang mochine oa CNC mokhoa oa ho tsamaisa lisebelisoa tsa oona tsa ho itšeha le workpiece ho finyella sephetho se lakatsehang. Mechini ea CNC e fetotse liindasteri tsa tlhahiso ka ho eketsa ts'ebetso, ho fokotsa liphoso tsa batho, le ho nolofalletsa tlhahiso ea likarolo tse rarahaneng le tse hlophisitsoeng.b. Mefuta ea Mechini ea CNC

Mechini ea CNC e tla ka mefuta e fapaneng, e 'ngoe le e' ngoe e etselitsoe lits'ebetso le liindasteri tse itseng. Mona ke mefuta e meng e tloaelehileng ea mechini ea CNC:- CNC siloa Mechini: Mechini ena e sebelisetsoa ho seha le ho bopa lisebelisoa ka ho potoloha lisebelisoa tsa ho seha. Ba sebelisoa haholo liindastering tse kang sefofane, likoloi, le ho sebetsa ka tšepe bakeng sa mesebetsi e kang ho cheka, ho sila le ho ngola.

- Lisebelisoa tsa CNC: Li-lathe tsa CNC li etselitsoe ho potoloha sesebediswa sa mosebetsi ha sesebelisoa sa ho itšeha se sebelisoa ho tlosa thepa ho sona. Li bohlokoa bakeng sa ho etsa likarolo tsa cylindrical, joalo ka thekos le Bushings.

- Li-routers tsa CNC: Mechini ena e sebelisoa haholo bakeng sa ho seha le ho etsa lintho tse kang lehong, polasetiki le likhomphutha. Li-routers tsa CNC li tloaelehile indastering ea mapolanka le ea ho etsa lipontšo.

- CNC Plasma Cutters: E loketse ho seha lipampiri tsa tšepe, li-cutters tsa plasma tsa CNC li sebelisa jete ea lebelo le phahameng la khase ea ionized ho qhibiliha le ho tlosa thepa. Ba hiriloe liindastering tsa tšepe le tsa likoloi.

- CNC Laser Cutters: Mechini ea ho itšeha ka laser e sebelisa lebone la laser e matla haholo ho seha kapa ho betla lisebelisoa tse fapaneng, ho kenyeletsoa litšepe, polasetiki le masela. Ba fumana lits'ebetso liindastering ho tloha ho ho etsa mabenyane ho isa ho tsa indasteri.

- CNC Waterjet Cutters: Li-waterjet cutters li sebelisa metsi a nang le khatello e phahameng ea metsi a kopantsoeng le likaroloana tsa abrasive ho khaola thepa. Li loketse ho seha mefuta e mengata ea thepa, ho akarelletsa lejoe, khalase le tšepe.

- Mechini ea CNC EDM: Mechini ea Motlakase ea Phallo ea Motlakase (EDM) e sebelisa lisebelisoa tsa motlakase ho senya thepa ho tloha mosebetsing. Li sebelisetsoa mesebetsi e rarahaneng le e nepahetseng haholo, haholo-holo ho lithulusi le ho etsa lintho.

c. Likarolo tsa mochini oa CNC

Ho utloisisa likarolo tsa mochini oa CNC ho bohlokoa bakeng sa ts'ebetso e sebetsang le tlhokomelo. Mona ke likarolo tsa bohlokoa tse fumanoang mecheng e mengata ea CNC:- Sebopeho sa Mochini: Sebopeho sa mochini se fana ka ts'ehetso ea sebopeho bakeng sa mochini oohle oa CNC. Hangata e entsoe ka thepa e boima ho netefatsa botsitso le ho tiea nakong ea ts'ebetso.

- Spindle: Spindle ke karolo ea enjene e ikarabellang bakeng sa ho ts'oara le ho potoloha lisebelisoa tsa ho itšeha kapa lihokelo. E bapala karolo ea bohlokoa molemong oa ho nepahala le lebelo la machining.

- Sistimi ea Axis: Mechini ea CNC e sebetsa ho ipapisitse le lilepe tse ngata, hangata li ngotsoe joalo ka X, Y, le Z. Lilepe tsena li hlalosa motsamao oa mochini sebakeng sa mahlakore a mararo. Mechini e meng e kanna ea ba le lilepe tse ling tse potolohang, joalo ka A, B, le C, bakeng sa ts'ebetso e rarahaneng.

- Sesebelisoa sa ho Fetola: Mechini e mengata ea CNC e na le li-changer tsa lisebelisoa tse ikemetseng tse lumellang ho fetoha ka potlako ha lisebelisoa tsa ho itšeha nakong ea ts'ebetso ea mochini. Sena se ntlafatsa ts'ebetso le ho fokotsa nako.

- Lekhotla la taolo: Phanele ea taolo e na le sebopeho seo basebelisi kapa baetsi ba mananeo ba ka kenyang litaelo, ho kenya mananeo, le ho beha leihlo boemo ba mochini.

- Sistimi e sebetsang kapa e sebetsang: Tafole ea mosebetsi ke moo workpiece e ts'oaretsoeng ka mokhoa o sireletsehileng nakong ea machining. Lisebelisoa tse fapaneng tsa ho sebetsa, joalo ka li-clamp, li-vises, le lihlopha, li sebelisetsoa ho etsa bonnete ba hore workpiece e lula e tsitsitse ebile e behiloe hantle.

- Tsamaiso ea ho khanna: Sistimi ea ho khanna e na le li-motors le li-activator tse ikarabellang bakeng sa ho tsamaisa likarolo tsa mochini ho latela lilepe tse boletsoeng. Taolo e nepahetseng ea sistimi ea ho khanna e bohlokoa bakeng sa ho sebetsa ka mokhoa o nepahetseng.

- Sistimi ea Pholiso: Ho phomola ho bohlokoa nakong ea bokhachane Multi Axis Cnc Machining ho thibela ho chesa haholo ha lisebelisoa le lisebelisoa tsa ho sebetsa. Mechini ea CNC hangata e na le sistimi e pholisang sebakeng sa ho boloka mocheso o nepahetseng.

- Laola Khomphutha: Khomphutha ea taolo e boloka lisebelisoa le software tse hlokahalang bakeng sa ho tsamaisa mochini oa CNC. E fetolela li-G-code le M-code tse hlahisoang ke software ea CAD/CAM le ho li fetolela metsamaong le liketsong.

Khaolo ea 2: Tokisetso ea Pele ea ho Kenya

Pele u qala ho kenya mochini oa hau oa CNC, ho bohlokoa ho etsa litokisetso tse phethahetseng. Khaolo ena e tla u tataisa ho latela lintlha tsa bohlokoa tsa pele ho instola, ho kenyelletsa ho seta sebaka sa mosebetsi, litlhoko tsa motlakase le motlakase, le mehato ea polokeho ho netefatsa ts'ebetso ea ts'ebetso e bonolo le e bolokehileng.a. Litlhaloso tsa sebaka sa mosebetsi

- Litlhoko tsa Sebaka: Qala ka ho lekola sebaka se teng ka har'a workshop kapa setsing sa hau. Netefatsa hore sebaka seo se sephara ka ho lekana ho amohela mochini oa hau oa CNC, ho kenyeletsoa sebaka se lekaneng sa phihlello le tlhokomelo e sireletsehileng. Nahana ka boholo ba mochini, sebaka se hlokahalang bakeng sa ho tšoara thepa, le lisebelisoa life kapa life tse ling kapa litsi tsa mosebetsi.

- Ho fafatsa: Ho bohlokoa hore moea o kene ka ho lekaneng bakeng sa ho qhala mocheso o hlahisoang nakong ea mochine le ho tlosa mosi leha e le ofe o ka bang kotsi kapa likaroloana tsa lerōle. Kenya mekhoa e nepahetseng ea ho kenya moea kapa thepa ea ho hloekisa moea ha ho hlokahala ho boloka sebaka sa mosebetsi se hloekileng le se sireletsehileng.

- Flooring: Etsa bonnete ba hore fatše sebakeng se khethiloeng ke boemo, bo tsitsitse, 'me bo khona ho tšehetsa boima ba mochine oa CNC. Mobu o sa lekaneng kapa o fokolang o ka lebisa ho sisinyeha ha mochine le ho se nepahale nakong ea ts'ebetso.

- Ho fihlella: Etsa moralo oa ho fihlella habonolo mochini oa CNC bakeng sa ho kenya, ho lokisoa le ho lokisoa. Etsa bonnete ba hore ho na le litsela tse hlakileng le sebaka se lekaneng sa ho tsamaisa mechine e boima le thepa.

- Leseli: Mabone a lekaneng a bohlokoa bakeng sa ts'ebetso e sireletsehileng le e nepahetseng. Netefatsa hore sebaka sa tšebetso se khantšitsoe hantle ho thibela likotsi le ho fana ka ponahalo e hlakileng ea tšebetso ea machining.

b. Litlhoko tsa Matla le Motlakase

- Phepelo ea Motlakase: Fumana litlhoko tse khethehileng tsa motlakase tsa mochini oa hau oa CNC. Sheba lintlha tsa tekheniki tsa mochini 'me u buisane le moetsi kapa mofani oa thepa ho netefatsa hore motlakase oa setsi sa hau o finyella litlhoko tsena.

- Voltage le Mokhahlelo: Mechini ea CNC e ka hloka maemo a fapaneng a motlakase (mohlala, 110V, 220V, 440V) le mekhahlelo (mohato o le mong kapa oa mekhahlelo e meraro). Netefatsa hore phepelo ea motlakase e lumellana le lintlha tsa mochini.

- Phanele ea Motlakase: Kenya phanele ea motlakase e inehetseng bakeng sa mochini oa CNC ho thibela ho jara lipotoloho tse seng li ntse li le teng. Hira ramotlakase ea nang le lengolo la tumello ho sebetsana le lithapo le likhokahano ka botsebi.

- Tšireletso ea ho eketseha: Tsetela ho lisebelisoa tsa ts'ireletso ho sireletsa lisebelisoa tsa elektroniki tsa mochini oa CNC ho tloha ho feto-fetoha ha motlakase le ho phahama ha motlakase.

- Ho khella fatše: Etsa bonnete ba hore mochini oa CNC le sistimi ea motlakase li behiloe hantle ho fokotsa kotsi ea likotsi tsa motlakase le tšenyo ea lisebelisoa.

c. Mehato ea Tšireletseho

- Lisebelisoa tsa polokeho: Beha polokeho pele ka ho fana ka lisebelisoa tse nepahetseng tsa ts'ireletso ea motho (PPE) bakeng sa basebetsi le litsebi. Sena se ka kenyelletsa likhalase tsa tšireletso, tšireletso ea kutlo, liatlana le liaparo tse sireletsang.

- Mekhoa ea Tšohanyetso: Ntlafatsa le ho ngola lits'ebetso tsa ho koala ts'ohanyetso tse ka emisang mochini oa CNC kapele haeba ho ka ba le liketsahalo tse sa lebelloang kapa likotsi. Netefatsa hore basebetsi bohle ba koetlisoa ka mekhoa ena.

- Polokeho ea Mollo: Kenya litima-mollo le lisebelisoa tsa ho lemoha mosi haufi le mochini oa CNC. Kenya ts'ebetsong melaoana ea ts'ireletso ea mollo, joalo ka ho boloka lisebelisoa tse tukang li le hole le mochini le ho boloka moralo oa ho tsoa mollong.

- Notlela/Tagout (LOTO): Kenya ts'ebetsong mekhoa ea LOTO ho thibela ho qala mochine ka phoso nakong ea tlhokomelo kapa tokiso. Sebelisa linotlolo le li-tag ho bontša ha mochini o ntse o sebetsoa.

- Koetliso ea Polokeho: Etsa koetliso e felletseng ea polokeho bakeng sa basebetsi bohle ba tla sebetsa, ba boloke, kapa ba sebetse ho potoloha mochini oa CNC. Totobatsa mekhoa e sireletsehileng le bohlokoa ba ho latela mekhoa ea tšireletso.

- Thuso ea pele: Boloka thepa ea thuso ea pele e nang le thepa e ngata sebakeng se haufi le mochini oa CNC. Netefatsa hore basebetsi ba koetlisitsoeng ba teng ho fana ka thuso ea pele hang-hang ha ho hlaha likotsi.

Khaolo ea 3: Ho Kopanya Mochini oa CNC

Hang ha u se u qetile litokiso tsa pele ho instola, ke nako ea ho fetela mohatong oa kopano. Khaolong ena, re tla fana ka tataiso ea mohato ka mohato mabapi le ho kopanya mochini oa hau oa CNC, ho akaretsa mesebetsi ea bohlokoa ho tloha ho e phutholla le ho e hlahloba ho isa taolong ea likhoele.a. Ho phutholla le ho Hlahloba

- u sa tsebe Qala ka ho manolla ka hloko likarolo tsohle tsa mochini oa hau oa CNC. Latela litaelo tsa moetsi bakeng sa ho phutholla ho qoba tšenyo leha e le efe nakong ea ts'ebetso. Sebelisa lisebelisoa tse loketseng le lisebelisoa tsa ho phahamisa ha ho hlokahala.

- Karolo ea Inventory: Etsa lethathamo la thepa ho netefatsa hore u fumane likarolo tsohle tse thathamisitsoeng bukeng kapa litokomaneng tsa mochini. Netefatsa hore ha ho letho le haellang kapa le senyehileng.

- Hlahloba Tšenyo: Hlahloba karolo e 'ngoe le e 'ngoe ka hloko bakeng sa matšoao leha e le afe a ho senyeha, joalo ka menoana, mengoapo kapa likarolo tse kobehileng. Ngola litaba leha e le life 'me u tsebise moetsi kapa mofani oa thepa hang-hang.

b. Ho Hlophisa Likarolo

- Hlophisa Sebaka sa Mosebetsi: Pele o kopanya, etsa bonnete ba hore sebaka sa hau sa mosebetsi se hloekile ebile se hlophisitsoe hantle. Hlakola bohlasoa bofe kapa bofe 'me u fane ka sebaka se lekaneng sa ho beha le ho hlophisa likarolo.

- Likarolo tse Tšoanang tsa Sehlopha: Kopanya likarolo tse tšoanang hammoho ho tsamaisa tšebetso ea kopano. Likarolo tse kang fasteners, masakaneng, le hardware li lokela ho hlophisoa ka lijana tse arohaneng kapa literei bakeng sa ho fihlella habonolo.

- Sheba Litaelo: Hlahloba libuka tsa kopano le litokomane tse fanoeng ke moetsi. Itloaetse ka mehato ea kopano, litšoantšo, le litaelo tse tobileng.

c. Ho kopanya Mochine oa Mochine

- Seboka sa Base: Qala ka motheo oa mochine oa CNC. Latela litaelo tsa moetsi ho kopanya foreimi ea motheo ka mokhoa o sireletsehileng. Netefatsa hore e boemong bo botle ebile e tsitsitse.

- Kholomo le Libopeho tsa Tšehetso: Kopanya litšiea le mehaho ea ts'ehetso, u li tsamaise ka nepo le motheo. Tobetsa liboutu le li-fasteners ho latela litekanyetso tse khothaletsoang tsa torque.

- Litataiso le Rails: Kenya litataiso le liporo tse tla tataisa motsamao oa likarolo tsa mochini o sehang kapa oa ho ts'oara lisebelisoa. Etsa bonnete ba hore li hlophisitsoe hantle 'me li khomaretsoe ka mokhoa o sireletsehileng.

d. Ho kopanya Motors le Drives

- Kemiso ea makoloi: Kenya li-motor maemong a tsona a khethiloeng ho latela litaelo tsa moetsi. Etsa bonnete ba hore li-motors li tlameletsoe ka mokhoa o sireletsehileng 'me li tsamaisana le mekhoa ea ho khanna.

- Tsamaiso ea ho khanna: Hokela li-motors ho mekhoa ea ho khanna u sebelisa likhokahano tse loketseng kapa mabanta. Etsa bonnete ba tsitsipano e nepahetseng le ho lumellana ho thibela ho khutlela morao le ho se nepahale.

e. Ho kenya Control Panel

- Ho kenya Panel ea Taolo: Kenya phanele ea taolo sebakeng se loketseng, hangata moo opareitara e fihlang habonolo. Netefatsa hore e behiloe ka mokhoa o sireletsehileng 'me e behiloe sebakeng sa hore e bonahale le ho fumaneha habonolo.

- Likhokelo tsa Motlakase: Hokela phanele ea taolo tsamaisong ea motlakase ea mochini ho latela lits'oants'o tsa lithapo tse fanoeng litokomaneng tsa moetsi. Lekola likhokahano tsohle habeli bakeng sa ho nepahala.

f. Tsamaiso ea Cable

- Ho tsamaisa Cable: Tsamaisa ka hloko lithapo tsohle, lithapo le liphaepe ka mokhoa o hlophisehileng ho thibela ho hohlana kapa ho kena-kenana le likarolo tse tsamaeang. Sebelisa literei kapa likotoana ho sireletsa le ho sireletsa likhoele.

- Ho ngola: Ngola lithapo le lithapo tse nang le matšoao kapa li-tag ho nolofatsa mathata le tlhokomelo. Tšoaea ka ho hlaka sepheo le moo thapo e eang teng.

- Tlhahlobo: Pele o koala liphanele kapa liphanele, etsa tlhahlobo ea pele ho netefatsa hore likhokahano tsohle tsa motlakase li sebetsa ka nepo. Netefatsa hore li-motor le li-sensor li arabela kamoo ho neng ho lebelletsoe.

Khaolo ea 4: Ho Lokisetsa le ho Beakanya Boemo

Khaolong ea 4, re tla shebana le ts'ebetso ea bohlokoa ea ho hokahanya le ho lekanya mochini oa hau oa CNC. Ho tsamaisana hantle le boemo bo nepahetseng ke tsa bohlokoa ho netefatsa ho nepahala le ho nepahala ha tšebetso ea mochini oa hau. Khaolo ena e akaretsa bohlokoa ba ho tsamaisana le maemo, lisebelisoa le lisebelisoa tse hlokahalang, le tataiso ea mohato ka mohato bakeng sa mokhoa oa ho tsamaisana le maemo.a. Bohlokoa ba Boiketlo le Boemo

- Ho Nepaha le ho Nepaha: Ho tsamaisana le maemo ho bohlokoa bakeng sa ho fihlela boemo bo phahameng ba ho nepahala le ho nepahala ho hlokahalang ho machining a CNC. Ho se leka-lekane kapa ho se leka-lekane ho ka lebisa liphosong tsa likarolo tse felileng.

- Ho Fokotsa Lekhalo: Ho tsamaisana hantle ho fokotsa khatello e sa hlokahaleng ea likarolo tsa mochine, joalo ka ho jaras le litsela. Sena se lelefatsa bophelo ba mochini le ho fokotsa litšenyehelo tsa tlhokomelo.

- Vibration e Nyenyane: Mochini o hlophisitsoeng hantle le o lekantsoeng o etsa hore ho thothomeloe ho fokolang, e leng se etsang hore ho be le lisebelisoa tse ntle le ho fokotseha ha lisebelisoa. Ho thothomela ho ka boela ha ama nako e telele ea ho phela ha likarolo tsa elektronike tse hlokolosi.

- Tšireletseho: Mechini e sa tsamaeeng hantle kapa e sa sebetseng hantle e ka baka likotsi tsa polokeho. Ka mohlala, mochine o seng boemong bo botle o ka 'na oa thekesela kapa oa sisinyeha ho sa lebelloa nakong eo o sebetsang.

b. Lisebelisoa le Lisebelisoa li Hlokahala

Ho etsa tekano le boemo bo nepahetseng, o tla hloka lisebelisoa le lisebelisoa tse latelang:- Maemo a Nepahetseng: Maemo a ho nepahala a boleng bo holimo a bohlokoa bakeng sa ho metha ka nepo ho tsepama ha mochini le boemo ba oona.

- Lisebelisoa tsa ho Fetola: Ho ipapisitse le moralo oa mochini oa hau, o ka hloka lisebelisoa tse ikhethileng joalo ka li-wrenches, li-shim, kapa li-screws.

- Lipontšo tsa ho daela: Lits'oants'o tsa ho daela li thusa ho lekanya ho tsamaisana ha likarolo tse fapaneng tsa mochini, ho kenyeletsoa spindle ea sesebelisoa le sesebelisoa sa ho sebetsa.

- Likhakanyo tsa Feeler: Li-gauge tsa li-feeler li sebelisetsoa ho lekanya likheo le ho hlaka pakeng tsa likarolo tsa mochine nakong ea ho tsamaisana.

- Alignment Laser: Laser ea alignment e ka ba molemo bakeng sa ho lekola ho otloloha ha litsela le likarolo tse ling tsa mela.

c. Mohato ka Mohato oa ho Lokisetsa le ho Beakanya Boemo

Latela mehato ena ho hokahanya le ho lekanya mochini oa hau oa CNC:Mohato oa 1: Lokisetsa Sebaka sa Mosebetsi

Netefatsa hore sebaka seo ho sebetsoang ho sona se hloekile, ha se na litšila, 'me se khantšitsoe hantle. Hlakola litšitiso leha e le life tse ka 'nang tsa sitisa ho lokisoa le ho leka-lekanya.Mohato oa 2: Ho Theha Lintlha tsa Reference

Khetha sebaka se tsitsitseng sa litšupiso holim'a foreimi ea mochini kapa setsi, hangata se fanoang ke moetsi. Ntlha ena e tla sebetsa e le sebaka sa ho qala litekanyo tsohle.Mohato oa 3: Lekola Mochini

- Beha maemo a nepahetseng libakeng tse fapaneng tsa mochini, joalo ka botlaaseng, litšiea, le tafole ea ho sebetsa.

- Fetola li-screws kapa li-shim tse lekanang ka moo ho hlokahalang ho finyella tlhophiso e nepahetseng. Sheba matšoao a bubble maemong a ho nepahala.

Mohato oa 4: Ho tsamaisana ha Litataiso le li-Slide

- Sebelisa matšoao a ho daela le li-laser tsa alignment ho lekola ho otloloha le ho bapisa ha litsela, li-slide, le likarolo tse ling tsa mela.

- Fetola likarolo tse loketseng ho lokisa ho se tsamaisane hofe kapa hofe ho fumanoeng.

Mohato oa 5: Ho tsamaisana ha Spindle

- Kenya sesupo sa ho daela holim'a spindle ea mochini kapa sets'oants'o sa sesebelisoa.

- Fetolela spindle ho bona hore na ha ho na metsi a mathang le hore na a tsepame hakae. Fetola spindle ha ho hlokahala ho fokotsa ho tsoa.

Mohato oa 6: Ho tsamaisana ha Worktable

- Lekola ho tsamaisana ha tafole ea ho sebetsa kapa ea ho sebetsa u sebelisa matšoao a ho daela.

- Fetola boemo ba tafole ea mosebetsi ho netefatsa hore e nepahetse ho lilepe tsa mochini.

- Ka mor'a liphetoho, hlahloba litlhophiso tsohle hape ho netefatsa hore li kopana le mamello e boletsoeng.

- Etsa liteko ho netefatsa hore mochini o sebetsa ka nepo mme o hlahisa liphetho tse lakatsehang.

Mohato oa 8: Litokomane

Boloka lirekoto tse qaqileng tsa tšebetso ea ho tsamaisana le maemo, ho kenyeletsoa litekanyo, litokiso tse entsoeng, le mathata afe kapa afe a kopaneng. Litokomane tsena li tla ba tsa bohlokoa bakeng sa tšebeliso le tlhokomelo nakong e tlang.Mohato oa 9: Tlhahlobo ea ho Qetela le Setifikeiti

Nahana ka ho ba le setsebi kapa moenjineri ea tšoanelehang ea etsang tlhahlobo ea ho qetela le setifikeiti ho netefatsa hore mochini oa CNC o kopana le maemo a indasteri le litlhoko tsa polokeho. Ho tsamaisana hantle le boemo ba maemo ho bohlokoa bakeng sa ts'ebetso e tšepahalang le e nepahetseng ea mochini oa hau oa CNC. Nka nako ea hau nakong ea ts'ebetso ena, kaha ho nepahala ke ntho ea bohlokoahali. Ka ho latela mehato ena le ho sebelisa lisebelisoa tse nepahetseng, o ka etsa bonnete ba hore mochini oa hau o maemong a nepahetseng bakeng sa ts'ebetso e atlehileng ea mochini. Khaolong e latelang, re tla hlahloba litlhoko tsa likhoele tsa motlakase bakeng sa mochini oa hau oa CNC.Khaolo ea 5: Mehala ea Motlakase

Khaolong ena, re tla hlahlobisisa likarolo tsa likhoele tsa motlakase tsa ho kenya mochini oa hau oa CNC. Lithapo tse nepahetseng tsa motlakase li bohlokoa bakeng sa ts'ebetso e bolokehileng le e sebetsang ea mochini. Khaolo ena e akaretsa kutloisiso ea litsamaiso tsa motlakase, ho thaepa mochini oa CNC, le mehato ea bohlokoa ea ts'ireletso.a. Ho utloisisa Litsamaiso tsa Motlakase

- Phepelo ea motlakase: Mechini ea CNC e hloka phepelo ea motlakase e tsitsitseng le e loketseng. Utloisisa litlhoko tsa motlakase, maqhubu le mekhahlelo e boletsoeng ke moetsi oa mochini. Netefatsa hore phepelo ea motlakase ea tšepahala ebile e na le matla a lekaneng a ho sebetsana le mojaro oa motlakase oa mochini.

- Phanele ea Motlakase: Mechini e mengata ea CNC e na le phanele ea motlakase e bolokang likarolo tse fapaneng, ho kenyeletsoa li-circuit breakers, relays, contactors, le li-terminal blocks. Itloaetse likarolo tsa phanele le mesebetsi ea tsona.

- Litšoantšo tsa Wiring: Hlahloba litšoantšo tsa lithapo tse fanoeng ke moetsi oa mochine. Litšoantšo tsena li bonts'a likhokahano lipakeng tsa likarolo 'me li bohlokoa bakeng sa likhoele tse nepahetseng.

- Ho khella fatše: Ho thea hantle ho bohlokoa bakeng sa polokeho. Netefatsa hore mochini le sistimi ea motlakase li thehiloe ho latela likhoutu tsa motlakase tsa lehae le likhothaletso tsa moetsi.

b. Ho kopanya mochine oa CNC

Latela mehato ena ho hokela mochini oa hau oa CNC:Mohato oa 1: Ho tima

Netefatsa hore mochini le mohloli oa matla li tingoe pele u qala mosebetsi ofe kapa ofe oa ho thaepa. Hakolla mochine mohloling oa matla.Mohato oa 2: Wiring Plan

Etsa moralo oa lithapo o ipapisitseng le litšoantšo tsa moetsi. Hlalosa likarolo, joalo ka li-motor, li-sensor, li-switches, le phanele ea taolo, 'me u tsebe hore na li hokahane joang.Mohato oa 3: Khetho ea Cable

Sebelisa lithapo tse loketseng le lithapo tse fihlelang matla a motlakase a mochini le litlhoko tsa hajoale. Netefatsa hore likhoele ke tsa mofuta o nepahetseng oa gauge le insurance.Mohato oa 4: Ho tsamaisa Cable

Tsamaisa lithapo le lithapo ka hloko litereneng tsa mochine kapa likotopo. Li boloke li hlophisehile 'me li arohane le likarolo tse tsamaeang ho thibela tšenyo.Mohato oa 5: Khokahano ea Terminal

Hokela lithapo ho litheminale tse nepahetseng ho likarolo tse kang lienjineri, lisensara, le li-switch. Netefatsa likhokahano tse sireletsehileng ka ho crimping kapa ho solder kamoo ho hlokahalang. Sebelisa lileibole tsa terata ho tsebahatsa habonolo.Mohato oa 6: Control Panel Wiring

Ka har'a phanele ea taolo, hokela lithapo ho li-terminal blocks, li-circuit breaker, li-contact, le li-relays joalo ka ha ho boletsoe litšoantšong tsa wiring. E-ba hlokolosi mosebetsing oa hau ho qoba likhokahano tsa marang-rang kapa lithapo tse hlephileng.Mohato oa 7: Khokahano ea Phepelo ea Matla

Hokela mochini ho phepelo ea motlakase ho latela litataiso tsa moetsi. Lekola litlhophiso tsa motlakase, mohato, le maqhubu ho netefatsa hore li lumellana le litlhoko tsa mochini.Mohato oa 8: Mehato ea Polokeho

Kenya ts'ebetsong likarolo tsa ts'ireletso joalo ka li-switches tsa ho emisa ts'ohanyetso le li-interlock tsa polokeho ha ho hlokahala. Netefatsa hore lisebelisoa tsena tsa polokeho li hokeletsoe ka nepo le ho lekoa hore na li sebetsa joang.Mohato oa 9: Ho etsa liteko

Pele o koala phanele ea taolo le ho matlafatsa mochini, etsa tlhahlobo ea ho tsoelapele ho bona hore na ha ho na liphoso tsa wiring kapa li-circuits tse khutšoane. Netefatsa hore likhokahano tsohle li bolokehile ebile ha li na likhoele tse hlephileng.c. Litlhokomelo tsa Tšireletso

- Notlela/Tagout (LOTO): Kenya ts'ebetso ea mekhoa ea LOTO ho thibela ho qala mochini ka phoso nakong ea ts'ebetso ea wiring kapa tokiso. Lisebelisoa tsa ho koala li lokela ho sebelisoa ho arola mehloli ea matla.

- Motlakase ea Tšoanelehang: Mosebetsi oa motlakase o lokela ho etsoa ke setsebi sa motlakase kapa setsebi se nang le tsebo se nang le tsebo ka litlhoko tsa motlakase oa mochine le likhoutu tsa motlakase tsa lehae.

- Tšireletso e fetang holimo: Kenya lisebelisoa tse nepahetseng tse sireletsang moroalo o mongata, joalo ka li-circuit breaker kapa fuse, ho thibela tšenyo haeba ho ka ba le mathata a motlakase.

- Ho khella fatše: Netefatsa hore mochini le likarolo tsohle tsa motlakase li theiloe hantle ho thibela likotsi tsa motlakase.

- Ho ngola: Ngola ka ho hlaka lithapo tsohle, lithapo, le likaroloana ho thusa ho rarolla mathata le ho lokisa nakong e tlang.

- Litlhahlobo tsa Kamehla: Nako le nako hlahloba sistimi ea motlakase bakeng sa matšoao a ho khathala, ho senyeha, kapa likhokahano tse hlephileng. Rarolla mathata afe kapa afe ka potlako.

- Mekhoa ea Tšohanyetso: Theha le ho buisana ka mekhoa ea tšohanyetso bakeng sa litaba tsa motlakase, ho kenyeletsoa mello ea motlakase kapa liketsahalo tsa ts'okelo ea motlakase.

Khaolo ea 6: Ho kenya Software ea Taolo

Khaolong ena, re tla hlahloba ts'ebetso ea ho kenya software bakeng sa mochini oa hau oa CNC. Software ea taolo ke boko ba sistimi ea hau ea CNC, e ikarabellang bakeng sa ho toloka le ho phethahatsa litaelo tsa machining. Khaolo ena e akaretsa kakaretso ea software ea taolo ea mochini oa CNC, tataiso ea mohato ka mohato bakeng sa ho kenya software, le mekhoa ea ho lekanya le ho etsa liteko.a. Kakaretso ea Software ea Taolo ea Mochini oa CNC

- Karolo ea Tsamaiso ea Software: Software ea taolo ea mochini oa CNC e ikarabella bakeng sa ho fetolela data ea moralo le lisebelisoa ho tsoa ho software ea CAD/CAM ho metsamao e itseng ea mochini. E hlahisa li-G-code le M-code tse laelang lienjene le li-activator tsa mochini.

- Mefuta ea taolo ea software: Ho na le mefuta e fapaneng ea software ea taolo ea CNC, ho tloha ho software ea thepa e fanoang ke baetsi ba mochini ho isa ho litharollo tsa mohloli o bulehileng le oa motho oa boraro. Khetha software e lumellanang le litlhoko tsa mochini oa hau le ho tloaelana le sebopeho sa eona.

- Likaroloana: Software ea ho laola e ka fapana ho ea ka likarolo le bokhoni. Batla software e fanang ka lits'ebetso tse hlokahalang bakeng sa litlhoko tsa hau tsa mochini tse ikhethileng, joalo ka tlhahiso ea lithulusi, liphetoho tsa lisebelisoa le taolo ea lebelo la spindle.

b. Ho kengoa ha Software ka Mehato

Latela mehato ena ho kenya software ea taolo bakeng sa mochini oa hau oa CNC:Mohato oa 1: Litlhoko tsa Sisteme

Lekola litlhoko tsa sistimi tse boletsoeng ke moetsi oa software ea taolo. Netefatsa hore komporo ea hau e fihlela litlhoko tsena ho latela hardware, sistimi e sebetsang, le memori e fumanehang.Mohato oa 2: Ho jarolla software kapa ho kenya Media

Fumana software ea taolo ka ho e jarolla sebakeng sa marang-rang sa moetsi kapa ka ho sebelisa mecha ea phatlalatso e fanoeng ke moetsi.Mohato oa 3: Ho kenya

- Tobetsa habeli faeleng ea ho instola software ho qala ts'ebetso ea ho instola.

- Latela litaelo tse skrineng tse fanoeng ke sets'oants'o. Sena se ka kenyelletsa ho khetha li-directory tsa ho kenya, ho amohela litumellano tsa laesense, le ho lokisa litlhophiso tsa software.

- Netefatsa hore ho instola ho atlehile, 'me ha ho na liphoso tse hlahang.

Mohato oa 4: Ho fana ka laesense le ts'ebetso

Haeba software ea taolo e hloka ho fuoa laesense kapa ts'ebetso, latela litataiso tsa moetsi ho phethela tšebetso ena. Netefatsa hore o na le linotlolo tsa laesense tse hlokahalang kapa likhoutu tsa ho kenya tshebetsong.Mohato oa 5: Tlhophiso ea Mochini

Lokisa software ea taolo ho tsamaisana le litlhaloso tsa mochini oa hau oa CNC. Sena se ka kenyelletsa ho beha liparamente bakeng sa lilepe tsa mochini, mefuta ea makoloi le likarolo tse ling tsa Hardware.Mohato oa 6: Tool and Material Database

Theha kapa kenya sesebelisoa le boitsebiso bo ka har'a software ea taolo. Tlhahisoleseding ena ke ea bohlokoa bakeng sa tlhahiso ea lisebelisoa le ho khetha liparamente tse nepahetseng tsa mochine.c. Teko le Teko

Kamora ho kenya software ea taolo, latela mehato ena bakeng sa ho lekanya le ho etsa liteko:Mohato oa 1: Tlhophiso ea Homing le Reference Point

- Home mochini ka ho suthisetsa lilepe tsohle litšupisong tsa tsona kapa maemong a hae. Sena se theha sebaka se tsebahalang sa ho qala motsamao oa mochini.

- Netefatsa hore mochini o khutlela sebakeng sa litšupiso ka nepo.

Mohato oa 2: Kemiso ea lisebelisoa

- Lekanya bolelele ba sesebelisoa le bophara ba sesebelisoa. Sena se tiisa hore mochini o tseba litekanyo tse nepahetseng tsa lisebelisoa tseo o tla li sebelisa.

- Etsa liteko tse fokolang kapa li-touch off routines ho netefatsa tlhophiso ea lisebelisoa.

Mohato oa 3: Setulo sa Workpiece

- Sireletsa sesebediswa sa teko kapa sesebediswa ho motjhini o sebetsang kapa wa ho sebetsa.

- Etsa bonnete ba hore workpiece e hlophisitsoe hantle ebile e sirelelitsoe.

Mohato oa 4: Liteko li matha

- Kenya lenaneo le bonolo la tlhahlobo ho software ea taolo.

- Etsa lenaneo la tlhahlobo ho bona metsamao ea mochini le liphetho tsa mochini.

- Sheba lintlha leha e le life tse kang ho sisinyeha ho sa lebelloang, ho thulana ha lisebelisoa, kapa ho se nepahale.

Mohato oa 5: Ho lokisa hantle

Haeba mathata a bonoa nakong ea tlhahlobo, lokisa litlhophiso tsa software ea taolo hantle, lisebelisoa tsa lithulusi, kapa ho seta lisebelisoa tsa mosebetsi ha ho hlokahala. Pheta teko ho fihlela mochine o sebetsa ka nepo le ka botšepehi.Mohato oa 6: Litokomane

Ngola liphetho tsohle tsa calibration le liteko, ho kenyeletsoa le liphetoho tse entsoeng ho software ea taolo. Litokomane tsena ke tsa bohlokoa bakeng sa ho sebelisoa nakong e tlang le ho rarolla mathata. Ho kenya software ea taolo ke mohato oa bohlokoa ts'ebetsong ea ho seta mochini oa CNC. Ka ho latela litaelo tsa moetsi, ho lekanya mochini, le ho etsa liteko tse phethahetseng, u ka etsa bonnete ba hore mochini oa hau oa CNC o se o loketse tlhahiso le hore o khona ho hlahisa liphetho tse nepahetseng le tse nepahetseng. Khaolong e latelang, re tla hlahloba bohlokoa ba ho tlotsa le tlhokomelo ho boloka ts'ebetso le nako e telele ea mochini oa hau oa CNC.Khaolo ea 7: Setlolo le Tlhokomelo

Khaolong ena, re tla shebana le lintlha tsa bohlokoa tsa ho tlotsa le ho hlokomela mochini oa hau oa CNC. Ho tlotsa ka mokhoa o nepahetseng le tlhokomelo ea kamehla li bohlokoa bakeng sa ho netefatsa nako e telele, ho nepahala le ho ts'epahala ha lisebelisoa tsa hau tsa CNC. Re tla akaretsa bohlokoa ba ho tlotsa, libaka tsa ho tlotsa, le ho theha kemiso ea tlhokomelo.a. Ke Hobane'ng ha Lubrication e le Bohlokoa

Lubrication e bapala karolo ea bohlokoa ts'ebetsong le bophelong bo bolelele ba mochini oa hau oa CNC ka mabaka a 'maloa:- Phokotso ea Khohlano: Ho tlotsa ho fokotsa khohlano lipakeng tsa likarolo tse tsamaeang, joalo ka li-bearings, litataiso le likurufu tsa bolo. Sena se fokotsa ho senyeha ha likarolo, ho lelefatsa bophelo ba tsona.

- Phokotso ea mocheso: Lisebelisoa li senya mocheso o hlahisoang nakong ea mechine, ho thibela ho futhumala ha likarolo tsa bohlokoa. Sena se thusa ho boloka ho nepahala ha dimensional le ho fokotsa kotsi ea ho eketseha ha mocheso.

- Tshebetso e boreleli: Lubrication e nepahetseng e netefatsa metsamao e bonolo le e nepahetseng haholoanyane ea likarolo tsa mochini. Sena se bohlokoa bakeng sa ho fihlela ho nepahala ho phahameng ho hlokehang mochining oa CNC.

- Thibela Corrosion: Lisebelisoa li fana ka thibelo e sireletsang khahlanong le mongobo le litšila, ho fokotsa kotsi ea ho senya holim'a tšepe.

- Ho fokotsa lithōle: Lubrication e ka fokotsa lerata le hlahisoang nakong ea ts'ebetso ea mochini, ea theha tikoloho e khutsitseng le e bonolo haholoanyane ea ho sebetsa.

b. Lintlha tsa Lubrication

Mechini e fapaneng ea CNC e na le lintlha tse fapaneng tsa lubrication tse hlokang tlhokomelo. Mona ke lintlha tse ling tse tloaelehileng tsa lubrication tse lokelang ho nahanoa:- Linear Guideways: Sebelisa lubricant ho litataiso tse melang, tse nolofatsang motsamao oa lilepe tsa mochini. Tsena li ka kenyelletsa likurufu tsa bolo, li-linear bearings, le li-slideways.

- Spindle Bearings: Tlotsa li-spindle bearings ho netefatsa ho potoloha ha bonolo le ho fokotsa khohlano nakong ea ts'ebetso ea ho seha kapa ea mochini.

- Mokhoa oa ho fetola lisebelisoa: Haeba mochine oa hau o na le mochine o fetolang lisebelisoa, etsa bonnete ba hore likarolo tse tsamaeang tsa mochine li tlositsoe ka mokhoa o lekaneng ho thibela jeme kapa ho se sebetse hantle.

- Li-gearboxes: Li-gearbox, haeba li le teng mochining oa hau, li ka hloka ho tlotsoa ka linako tse itseng ho boloka ts'ebetso le ho fokotsa ho khathala.

- Li-Screws tsa Ball: Li-screws tsa bolo ke likarolo tsa bohlokoa mochining oa CNC. Lubrication e nepahetseng ea li-screws tsa bolo le likarolo tsa tsona tse amanang le tsona ke tsa bohlokoa bakeng sa boemo bo nepahetseng le ho sisinyeha.

- Pompo e Pholisang: Haeba mochini oa hau o sebelisa sesebelisoa sa ho pholisa, etsa bonnete ba hore pompo e tlositsoe ka mokhoa o nepahetseng le hore sepholisa se hloekile ebile ha se na litšila.

- Axis Motors: Ho ipapisitse le mofuta oa li-motors tse sebelisoang bakeng sa motsamao oa axis (mohlala, stepper kapa servo), latela likhothaletso tsa moetsi bakeng sa lubrication kapa tlhokomelo.

- Litiiso le Li-Gaskets: Hlahloba le ho kenya litiiso tse tsofetseng kapa tse senyehileng le li-gaskets ha ho hlokahala ho thibela ho lutla le ho silafala ha lubricant.

c. Kemiso ea Tlhokomelo

Ho theha kemiso ea kamehla ea tlhokomelo ho bohlokoa ho boloka mochini oa hau oa CNC o le maemong a nepahetseng. Mehato ea ho etsa kemiso ea tlhokomelo ke ena:Mohato oa 1: Tataiso ea Moetsi

Sheba litokomane tsa moetsi le likhothaletso bakeng sa linako tsa tlhokomelo, mefuta ea ho tlotsa, le mekhoa e ikhethileng.Mohato oa 2: Tlhokomelo ea Letsatsi le Letsatsi

Kenya tšebetsong mekhoa ea tlhokomelo ea letsatsi le letsatsi e kenyelletsang mesebetsi e kang ho hleka maloanlahla, ho hlahloba li-fasteners tse hlephileng, le ho hlahloba maemo a pholiso. Mesebetsi ena e thusa ho thibela mathata a manyane hore a se ke a mpefala.Mohato oa 3: Tlhokomelo ea Beke kapa Khoeli le Khoeli

Rulahanya mesebetsi e tebileng ea tlhokomelo beke le beke kapa khoeli le khoeli, ho latela tšebeliso ea mochini oa hau. Sena se ka kenyelletsa ho hloekisa ka botlalo, ho tlotsa le ho hlahloba likarolo tsa bohlokoa.Mohato oa 4: Tlhokomelo ea Kotara kapa Karolo ea Selemo

Etsa mesebetsi e batsi ea ho lokisa, joalo ka ho hlahloba le ho lokisa tsela, ho hlahloba likhokahano tsa motlakase, le ho kenya likarolo tse tsofetseng kapa tse senyehileng.Mohato oa 5: Tlhokomelo ea Selemo le Selemo

Selemo le selemo, nahana ka tlhahlobo e felletseng ea setsebi kapa moenjiniere ea tšoanelehang. Sena se lokela ho kenyelletsa potoloho e felletseng ea lubrication, licheke tsa calibration, le tokiso efe kapa efe e hlokahalang kapa tse ling.Mohato oa 6: Litokomane

Boloka lirekoto tse qaqileng tsa mesebetsi eohle ea tokiso, ho kenyeletsoa matsatsi, mesebetsi e entsoeng, le litaba life kapa life tse hloailoeng. Litokomane tsena li bohlokoa bakeng sa ho sala morao nalane ea mochini le ho rera ho lokisoa ha nako e tlang.Mohato oa Pele: Koetliso

Etsa bonnete ba hore basebetsi ba ikarabellang bakeng sa tlhokomelo ba koetlisoa ka ho lekaneng le ho fumana lisebelisoa le lisebelisoa tse hlokahalang. Ho tlotsa le ho lokisoa khafetsa ho bohlokoa bakeng sa ho holisa nako ea bophelo le ts'ebetso ea mochini oa hau oa CNC. Ka ho latela kemiso e hlophisitsoeng hantle ea tlhokomelo le ho sebetsana le lintlha tsa ho tlotsa, o ka thibela ho roala pele ho nako le ho netefatsa hore mochini oa hau o tsoela pele ho hlahisa lisebelisoa tse nepahetseng le tsa boleng bo holimo. Khaolong e latelang, re tla tšohla mekhoa ea polokeho le litataiso tsa ho sebelisa mochini oa hau oa CNC.Khaolo ea 8: Mekhoa ea Tšireletso bakeng sa Mechini ea CNC

Tšireletseho ke ea bohlokoa ka ho fetisisa ha u sebetsa le mechine ea CNC. Khaolong ena, re tla hlahloba mekhoa ea bohlokoa ea ts'ireletso le tataiso bakeng sa ho sebetsa mechine ea CNC, ho kenyelletsa le ts'ireletso ea mochine oa CNC, mekhoa ea ho koala ha tšohanyetso, le tšebeliso ea thepa ea tšireletso ea botho (PPE).a. Tšireletseho ea Mochini oa CNC

- Koetliso: Netefatsa hore basebetsi bohle ba sebetsang kapa ba sebetsang haufi le mechini ea CNC ba fumane koetliso e felletseng ea polokeho. Sena se lokela ho kenyelletsa koetliso e tobileng mochini, mekhoa e bolokehileng ea ts'ebetso, le temoho ea kotsi.

- Balebeli ba Mechini: Boloka balebeli bohle ba mochini le li-interlocks tsa polokeho li le teng 'me li sebetsa ka nepo. Likarolo tsena tsa polokeho li etselitsoe ho sireletsa basebelisi likarolong tse tsamaeang le likotsi tse ka bang teng.

- Li-Labels tsa Tšireletso: Netefatsa hore lileibole tsa polokeho le mats'oao a lemosang li hlahisoa ka mokhoa o hlakileng mochining. Litlaleho tsena li fana ka lintlha tsa bohlokoa mabapi le likotsi tse ka bang teng le mehato ea tšireletso.

- Emergency Stop: Tseba basebetsi ka sebaka le ho sebelisa konopo ea ho emisa ts'ohanyetso. Netefatsa hore e fumaneha habonolo ha ho ka hlaha maemo a tshohanyetso.

- Hlakola Sebaka sa Mosebetsi: Boloka sebaka sa ho sebetsa se se nang bohlasoa ho potoloha mochini oa CNC. Tlosa lisebelisoa leha e le life tse sa hlokahaleng, lisebelisoa, kapa litšila tse ka bakang kotsi ea ho khoptjoa kapa tsa kena-kenana le ts'ebetso ea mochine.

- Ho Koalloa ha Mochini/Tagout (LOTO): Kenya ts'ebetsong mekhoa ea ho koala / ea ho kenya letsoho ho fokotsa matla le ho sireletsa mochine pele o lokisa kapa o lokisa. Lisebelisoa tsa ho koala li thibela ho qala mochine ka phoso.

- Tšireletseho ea Spindle le Lisebelisoa: Tšoara lisebelisoa tsa ho itšeha le liphetoho tsa lisebelisoa ka hloko. Etsa bonnete ba hore lisebelisoa li sirelelitsoe ka nepo ho li-toolholders le hore liphetoho tsa lisebelisoa li etsoa ho latela mekhoa e sireletsehileng.

- Tšebeliso ea Lintho: Sebelisa lisebelisoa le mekhoa e nepahetseng ea ho phahamisa ha u tšoara thepa e boima kapa lisebelisoa tsa mosebetsi. Qoba ho jarisa boima ba boima ba mochini.

- Polokeho ea Mollo: Beha litima-mollo le lisebelisoa tse lemohang mosi haufi. Theha le ho buisana le mekhoa ea ts'ireletso ea mollo, ho kenyeletsoa sebaka sa ho tsoa ha mollo le mekhoa ea ho tsoa.

b. Mekhoa ea ho Koala ha Tšohanyetso

- Konopo ea Emergency Stop: Boemong ba tšohanyetso kapa ha ho hlokahala hore ho koaloe hanghang, tobetsa konopo ea ho emisa ts'ohanyetso. Konopo ena hangata e kholo, e khubelu, 'me e fumaneha habonolo.

- Emisa Tsohle Tsohle: Konopo ea ho emisa ts'ohanyetso e lokela ho emisa metsamao eohle ea mochini le ho koala motlakase mochining. Etsa bonnete ba hore mochine o ema ka ho feletseng.

- Lockout/Tagout: Kamora ho sebelisa konopo ea ho emisa ts'ohanyetso, latela mekhoa ea ho notlela / tagout ho sireletsa mochini le ho thibela ho qala bocha ka phoso.

- Tsebisa Ba boholong: Haeba kotsi kapa boemo bo kotsi bo etsahala, ikopanye le balaoli ba loketseng, joalo ka basebetsi ba tlhokomelo kapa baokameli, ho rarolla bothata le ho netefatsa hore mochini o bolokehile hore o ka sebetsa hape.

c. Thepa ea Tšireletso ea Motho (PPE)

- Likhalase tsa Polokeho: Basebelisi le basebetsi ba haufi le mochini oa CNC ba lokela ho roala likhalase tsa tšireletso tse nang le ts'ireletso e nepahetseng ho sireletsa mahlo a bona ho litšila tse fofang.

- Ts'ireletso ea kutlo Mabenkeleng a mechine e lerata, tšireletso ea kutlo, e kang li-earmuffs kapa earmuffs, e lokela ho apesoa ho thibela tšenyo ea kutlo.

- Litlelafo Ha u tšoara thepa kapa u etsa mesebetsi ea tlhokomelo, roala liatlana tse loketseng mosebetsi oo. Netefatsa hore liatlana ha li behe kotsi haufi le likarolo tsa mochini o tsamaeang.

- Tšireletso ea ho Phefumoloha: If lisebelisoa tsa machinings hlahisa lerole kapa mosi, sebelisa lisebelisoa tsa ts'ireletso ea ho hema, joalo ka limaske tsa lerole kapa li-respirator, ho itšireletsa khahlanong le likotsi tsa ho hema.

- Safety Shoes: Apara lieta tse tiileng tsa tšireletso kapa lirifi tse nang le li-soles tse thibelang ho thella ho itšireletsa khahlanong le likotsi tsa maoto le ho etsa bonnete ba ho ts'oara hantle sebakeng sa mosebetsi.

- Liaparo tse Sireletsang: Ho ipapisitse le ts'ebetso ea mochini le lisebelisoa tse sebelisitsoeng, apara liaparo tse loketseng tse sireletsang, joalo ka liaprone kapa likoahelo tsa 'mele o felletseng.

- Lihelmete tsa Tšireletso: Libakeng tseo ho tsona lintho tse oelang li leng kotsi, roala lihelmete tsa tšireletso kapa likatiba tse thata bakeng sa tšireletso ea hlooho.

- Lithebe tsa Sefahleho: Bakeng sa mesebetsi e amanang le likotsi tse ka bang teng sefahlehong, joalo ka ho fafatsa sepholi kapa lichipisi, sebelisa lithebe tsa sefahleho hammoho le likhalase tsa tšireletso.

Khaolo ea 9: Ho Rarolla Mathata a Tloaelehileng a Kenyelletso

Khaolong ena, re tla hlahloba mathata a tloaelehileng a ka 'nang a hlaha nakong ea ho kenngoa ha mechine ea CNC le ho fana ka tharollo ea ho rarolla mathata ana. Ho phaella moo, re tla tšohla mekhoa ea ho rarolla mathata e ka u thusang ho tseba le ho rarolla mathata ka katleho.a. Mathata a Tloaelehileng le Litharollo

-

Mathata a Motlakase:

- bothata: Mochini oa CNC o ke ke oa sebetsa.

- tharollo: Sheba mohloli oa matla, likhokahano tsa motlakase, le li-fuse. Netefatsa hore konopo ea ho emisa ts'ohanyetso e lokollotsoe.

-

Ho se tsamaisane hantle ha Mechini:

- bothata: Mochine o hlahisa likarolo tse sa nepahalang kapa litekanyo tsa mosebetsi.

- tharollo: Fetola 'me u ntlafatse mochine. Sheba likarolo tse hlephileng kapa litataiso tse tsofetseng 'me u li khutlisetse ha ho hlokahala.

-

Tool Chatter kapa Vibration:

- bothata: Mochine o hlahisa li-vibrations kapa moqoqo oa lisebelisoa, o amang holimo holimo.

- tharollo: Sheba sets'oants'o sa lisebelisoa le collet ea spindle bakeng sa litulo tse nepahetseng. Fetola litlhophiso tsa ho itšeha le litlhophiso tsa litsela tsa lisebelisoa.

-

Liphoso tsa Puisano:

- bothata: Molaoli oa CNC ha a khone ho buisana le komporo kapa software ea CAD/CAM.

- tharollo: Netefatsa likhokahano tsa lithapo, litefiso tsa baud, le litlhophiso mochining le komporong. Etsa bonnete ba hore software e nepahetseng le lisebelisoa tsa mokhanni.

-

Ho robeha ha lisebelisoa:

- bothata: Lisebelisoa li atisa ho robeha nakong ea mochine.

- tharollo: Lekola tlhophiso ea lisebelisoa, boemo ba setšoantšisi, le ho felloa ke li-spindle. Fetosa liphepelo le lebelo ho ipapisitse le lisebelisoa tsa lisebelisoa le mosebetsi.

-

Mathata a ho Pholisa kapa a Lubrication:

- bothata: Phallo ea pholiso/lubrication e sa lekaneng kapa e sa lekana.

- tharollo: Lekola likarolo tsa sistimi e futhumatsang le ea lubrication, joalo ka lipompo, li-hoses le li-nozzles. Hloekisa kapa u fetole lihloela 'me u netefatse hore maemo a mokelikeli a nepahetseng.

-

Liphoso tsa Software:

- bothata: Software ea taolo e bonts'a melaetsa ea liphoso kapa boitšoaro bo sa lebelloang.

- tharollo: Hlahloba melaetsa ea liphoso le ho sheba litokomane tsa software. Sheba mathata a ho lumellana le ho ntlafatsa software kapa firmware ha ho hlokahala.

b. Mekhoa ea ho rarolla mathata

- Mokhoa o hlophisitsoeng: Ha u rarolla mathata, sebelisa mokhoa o hlophisitsoeng ka ho tseba le ho khetholla mohloli oa bothata. Qala ka licheke tse hlakileng ka ho fetesisa 'me u tsoele pele ho batlisisa lisosa tse rarahaneng.

- Litokomane: Sheba libuka tsa mochini, litokomane, le lisebelisoa tse fanoeng ke moetsi bakeng sa tataiso ea tharollo le litlhaloso tsa khoutu ea liphoso.

- Tekanyo le Teko: Sebelisa lisebelisoa tsa ho metha joalo ka lits'oants'o tsa ho daela, li-caliper, le li-micrometer ho lekola tekano, boholo, le ho felloa ke lisebelisoa. Etsa likheo tsa liteko ho netefatsa ho nepahala ha mochini.

- Tlhahlobo ea Pono: Etsa tlhahlobo e feletseng ea pono ea mochine, ho hlahloba li-fasteners tse hlephileng, likarolo tse senyehileng, kapa matšoao a bonahalang a ho senyeha.

- Litlaleho le Litlaleho: Lekola lintlha tsa tlhokomelo, lintlha tsa liphoso, le lirekoto tsa litaba tse fetileng ho tseba mathata kapa lipaterone tse hlahang khafetsa.

- Ikopanye le Litsebi: Haeba u kopana le mathata a thata kapa a phehellang, buisana le litsebi, joalo ka tšehetso ea tekheniki ea moetsi, litsebi tse tšoanelehang, kapa bo-machini ba nang le boiphihlelo ba ka 'nang ba kopana le mathata a tšoanang.

- Safe Solutions Kamehla netefatsa polokeho nakong ea ho rarolla mathata. Latela mekhoa ea ho notlela kantle, tima mochini, 'me u sebelise thepa e nepahetseng ea ho itšireletsa (PPE).

- Litokomane: Boloka lirekoto tse qaqileng tsa mesebetsi ea ho rarolla mathata, ho kenyeletsoa mehato e nkuoeng, litebello, le liqeto tse sebelisitsoeng. Lirekoto tsena e ka ba tsa bohlokoa bakeng sa ho sebelisoa nakong e tlang.

- Thuto e Tsoelang Pele: Khothaletsa moetlo oa ho tsoela pele ho ithuta le ho arolelana tsebo har'a sehlopha sa hau. Boiphihlelo bo fumanoeng ka ho rarolla mathata bo ka lebisa mekhoeng e ntlafetseng ea thibelo.

Khaolo ea 10: Licheke tsa ho Qetela le Teko

Khaolong ena e phethelang, re tla tšohla mehato ea bohlokoa ea ho tsamaisa mananeo a tlhahlobo, ho netefatsa ho nepahala, le ho lokisa mochini oa hau oa CNC hantle ho fihlela ts'ebetso e nepahetseng.a. Mananeo a ho tsamaisa liteko

- Khetho ea Mananeo a Teko: Lokisetsa mananeo a liteko a kenyelletsang mefuta e mengata ea ts'ebetso ea mochini oa CNC eo o tla e etsa. Mananeo ana a lokela ho kenyelletsa metsamao ea mantlha, liphetoho tsa lisebelisoa, le maemo a fapaneng a ho itšeha.

- Sethapo sa lisebelisoa le mosebetsi: Beha lisebelisoa tse nepahetseng 'me u boloke sekhechana sa tlhahlobo holim'a tafole ea mochini kapa sesebelisoa sa mochini. Etsa bonnete ba hore lisebelisoa le li-offsets tsa mosebetsi li hlophisitsoe hantle.

- Dry Run: Qalong, etsa ho omella ntle le ho itšeha. Sena se o lumella ho lekola metsamao ea mochini, liphetoho tsa sesebelisoa, le phallo ea lenaneo ka kakaretso bakeng sa liphoso leha e le life kapa boitšoaro bo sa lebelloang.

- Khetho ea Boitsebiso: Khetha thepa ea tlhahlobo e ts'oanang le eo u rerileng ho e sebelisa bakeng sa merero ea hau ea 'nete ea mochini. Sena se tiisa hore liphetho tsa liteko li etsisa maemo a sebele a lefatše.

- Liteko tsa ho Seha: Phetha mananeo a tlhahlobo ka ts'ebetso ea ho itšeha. Lekola ts'ebetso ea mochini, u ele hloko ho nepahala ha lithulusi, lebelo la spindle, le litefiso tsa phepelo.

b. Ho Etsa bonnete ba ho Nepaha

- Tekanyo le Tlhahlobo: Kamora ho etsa li-program tsa liteko, lekanya litekanyo le pheletso ea bokaholimo ba lisebelisoa tsa tlhahlobo u sebelisa lisebelisoa tse nepahetseng tsa ho metha. Bapisa liphetho le litlhaloso tse reriloeng tsa moralo.

- Tlhahlobo ea Lisebelisoa: Lekola lisebelisoa tsa ho itšeha bakeng sa matšoao a ho felloa ke matla, joalo ka maqeba a chesitsoeng kapa moaparo o fetelletseng oa lisebelisoa. Fetola kapa o chorisa lisebelisoa hape ha ho hlokahala.

- Tlhahlobo ea Mosebetsi: Lekola sesebediswa sa tlhahlobo bakeng sa bofokodi bofe kapa bofe, mathata a ho qetela, kapa ho kgeloha ho tswa ho geometry e batlwang. Shebana le lintlha life kapa life tse hloahloa nakong ea tlhahlobo.

- Maikutlo le Tlhahlobo: Sekaseka liphetho tsa liteko ho bona ho se lumellane hofe kapa hofe kapa ho fapoha ho tsoa ho liphetho tse lebelletsoeng. Etsa qeto ea hore na ho hlokahala liphetoho ho ntlafatsa ho nepahala.

c. Choriso

- Toolpath Optimization: Haeba liphetho tsa liteko li senola ho se nepahale kapa mathata a ho qetela, nahana ka ho ntlafatsa litsela tsa lisebelisoa ho software ea hau ea CAM. Fetola liparamente tsa litsela tsa lisebelisoa, khetho ea lisebelisoa, le lebelo la ho itšeha le lijo ha ho hlokahala.

- Liphetoho tsa Paramethara ea Mochini: Sheba litokomane tsa mochini ho lokisa maemo a itseng, joalo ka ho potlakisa, ho theola lebelo, le matšeliso a morao. Liphetoho tsena li ka ntlafatsa ho nepahala.

- Tool Offset Calibration: Fetola li-offsets tsa lisebelisoa ha ho hlokahala. Netefatsa hore mochini o lefella bolelele le bophara ba sesebelisoa ka nepo, o fokotsa liphoso ho machining.

- Tokiso ea Mosebetsi: Sheba le ho lokisa li-offsets tsa mosebetsi ho netefatsa hore mochini o beha sesebelisoa hantle se ipapisitseng le mosebetsi. Liphoso tse nyane mabapi le ho fokotsa mosebetsi li ka lebisa ho se nepahaleng ho hoholo.

- Teko-bocha: Kamora ho etsa litokiso le ho hlophisa hantle, tsamaisa mananeo a tlhahlobo hape ho netefatsa lintlafatso tsa ho nepahala le pheletso ea bokaholimo.

- Litokomane: Ngola mesebetsi eohle ea tokiso, liphetoho, le liphetho tsa liteko bakeng sa litšupiso tsa nako e tlang. Litokomane tsena li tla ba tsa bohlokoa bakeng sa ho boloka botsitso ts'ebetsong ea hau ea mochini.

Khaolo ea 11: Koetliso le Ntlafatso ea Tsebo

Khaolong ena, re tla hatisa bohlokoa ba koetliso le nts'etsopele ea litsebo bakeng sa basebetsi ba mechine le basebetsi ba tlhokomelo. Koetliso e nepahetseng le ntlafatso ea bokhoni li bohlokoa bakeng sa ho netefatsa ts'ebetso e bolokehileng le e sebetsang ea mochini oa CNC, hammoho le ho hlokomela le ho rarolla lisebelisoa hantle.a. Koetliso ea Basebetsi

- Ts'ebetso ea mantlha ea mochini: Basebelisi ba lokela ho fumana koetliso e felletseng mabapi le lintlha tsa mantlha tsa ts'ebetso ea mochini oa CNC, ho kenyelletsa ho qala mochini, ho koala, ho matha le ho matha.

- Ho utloisisa G-code le M-code: Basebelisi ba lokela ho ba le tsebo ea ho toloka le ho fetola li-G-code le M-code, tse laolang motsamao le tšebetso ea mochini.

- Ho sebetsana le lisebelisoa: Mekhoa e nepahetseng ea ho sebetsana le lisebelisoa, ho kenyelletsa le liphetoho tsa lisebelisoa, lisebelisoa tsa lisebelisoa, le ho lekanya lisebelisoa, li bohlokoa ho thibela likotsi le ho netefatsa ho nepahala ha mochine.

- Setulo sa Workpiece: Koetliso e lokela ho akaretsa setupo sa mosebetsi, ho kenyeletsoa ho ts'oara mosebetsi, ho kenya thepa, le ho boloka li-workpieces ho tafole ea ho sebetsa kapa ea mochini.

- Mekhoa ea Tšireletso: Basebelisi ba tlameha ho tseba mekhoa ea ts'ireletso ea mochini oa CNC, liprothokholo tsa ho koala ha tšohanyetso, le ts'ebeliso ea lisebelisoa tsa ts'ireletso ea motho (PPE).

- Metheo ea ho rarolla mathata: Tsebo ea mantlha ea ho rarolla mathata, joalo ka ho tseba litaba tse tloaelehileng le ho tseba nako ea ho batla thuso, e ka thusa basebelisi ho rarolla mathata a manyane hang-hang.

- Tlhophiso ea boleng: Koetliso ea mekhoa ea ho laola boleng le ho hlahloba e bohlokoa ho netefatsa hore lisebelisoa tse felileng li kopana le mamello e boletsoeng le litlhoko tsa ho qetela.

- Ketsiso le Boitlhakiso: Basebelisi ba lokela ho ba le menyetla ea ho ikoetlisa ka matsoho le ho etsa ketsiso ho ntlafatsa litsebo tsa bona le ho aha boits'epo mabapi le ho sebelisa mochini oa CNC.

b. Koetliso ea Paballo

- Tlhokomelo e Thibelang: Basebeletsi ba tlhokomelo ba lokela ho fumana koetliso mabapi le mesebetsi ea ka mehla ea tokiso e tobileng mochini oa CNC, ho kenyeletsoa ho tlotsa, ho hloekisa le mekhoa ea ho hlahloba.

- Likaroloana tsa Mochini: Kutloisiso e tebileng ea likarolo tsa mochini, ho kenyeletsoa li-motor, li-sensor, li-drive, le litsamaiso tsa motlakase, lia hlokahala bakeng sa basebetsi ba tlhokomelo ho hlahloba le ho rarolla mathata ka nepo.

- Mekhoa ea ho rarolla mathata: Tsebo e tsoetseng pele ea ho rarolla mathata, joalo ka ho hlahloba mathata a motlakase, mochini le software, a bohlokoa bakeng sa ho fokotsa nako le ho ntlafatsa ts'ebetso ea mochini.

- Taolo ea Lubrication le Mekelikeli: Tsebo e nepahetseng ea lintlha tsa lubrication, mefuta ea mokelikeli le lisebelisoa tsa ho hloekisa li bohlokoa bakeng sa ho boloka botšepehi ba mochine.

- Sistimi ea Motlakase: Basebeletsi ba tlhokomelo ba lokela ho koetlisetsoa lits'ebetso tsa motlakase, ho kenyeletsoa ho utloisisa lits'oants'o tsa lithapo, liprothokholo tsa polokeho ea motlakase, le ho nkela likarolo tsa motlakase sebaka.

- Ntlafatso e tsoetseng pele: Koetliso ea mekhoa e tsoetseng pele ea ho lekanya, joalo ka ho tsamaisana le laser le tekanyo ea ho phalla ha spindle, e ka ntlafatsa ho nepahala ha mochini oa CNC.

- Lisebelisoa tsa Software: Ho tloaelana le liapdeite tsa software le lintlafatso tsa firmware ho bohlokoa ho boloka software ea taolo le firmware ea mochini e ntse e le teng.

c. Ntlafatso ea Tsebo

- Thuto e Tsoelang Pele: Khothaletsa moetlo oa ho tsoela pele ho ithuta har'a basebetsi le basebetsi ba tlhokomelo. Sena se ka kenyelletsa ho ea lithupelong, lithupelong, le lithutong tsa marang-rang tse amanang le theknoloji ea CNC.

- Tekolo ea Bokhoni: Nako le nako hlahloba litsebo le tsebo ea basebetsi le basebetsi ba tlhokomelo ho fumana libaka tsa ntlafatso le koetliso e lebisitsoeng.

- Koetliso e fapaneng: Nahana ka basebetsi ba lithupelo tse fapaneng mesebetsing ea mantlha ea tlhokomelo le ka tsela e fapaneng. Sena se ka ntlafatsa kutloisiso le tšebelisano-'moho ka har'a sehlopha.

- Mentorship: Kenya ts'ebetsong mananeo a tlhabollo moo basebetsi ba nang le boiphihlelo ba ka fanang ka tataiso le ho arolelana tsebo ea bona le litho tsa sehlopha tse se nang boiphihlelo.

- Ho Rarolla Mathata: Khothaletsa basebetsi ho ikakhela ka setotsoana lithupelong tsa ho rarolla mathata le ho hlahloba sesosa sa sesosa, ho khothaletsa moetlo oa ho rarolla mathata.

- Maikutlo a Loop: Theha mokhoa oa ho fana ka maikutlo moo basebetsi le basebetsi ba tlhokomelo ba ka buisanang ka litaba, ba arolelana lintlha, le ho fana ka maikutlo a ntlafatso ea ts'ebetso ea mochini le tlhokomelo.

fihlela qeto e

Tataisong ena e felletseng, re hlahlobile ts'ebetso e rarahaneng ea ho kenya mochini oa CNC, e buang ka lihlooho tse fapaneng ho netefatsa hore mochini oa hau oa CNC oa bokelloa, oa kengoa, 'me o sebetsoa ka nepo le ka polokeho. Ha re akaretseng lintlha tsa bohlokoa, re totobatse bohlokoa ba ho kenya mochini o nepahetseng oa CNC, 'me re lebelle bokamoso ba theknoloji ea CNC.a. Kakaretso ea Lintlha tsa Bohlokoa

Ka tataiso ena, re kentse lintlha tse latelang tsa bohlokoa:- Ho utloisisa Mechini ea CNC: Re qalile ka ho buisana ka hore na mechini ea CNC ke efe, mefuta e fapaneng e teng, le likarolo tsa eona tsa bohlokoa.

- Tokisetso ea Pele ho Kena: Re hatelletse bohlokoa ba ho lokisa sebaka sa mosebetsi, ho fihlela litlhoko tsa matla le motlakase, le ho kenya ts'ebetsong mehato ea polokeho pele ho ts'ebetso.

- Ho kopanya mochini oa CNC: Ho ile ha fanoa ka mehato e qaqileng bakeng sa ho phutholla, ho hlophisa likarolo, ho kopanya foreime ea mochine, ho hokela lienjene le li-drive, ho kenya li-control panel le ho laola lithapo.

- Ho hlophisoa le ho lekanya: Re buisane ka bohlokoa ba ho ikamahanya le maemo, lisebelisoa tse hlokahalang, le mehato ea mohato ka mohato ho finyella ho nepahala ho nepahetseng.

- Wiring ea Motlakase: Ho utloisisa litsamaiso tsa motlakase, ho thaepa mochini oa CNC, le ho latela mehato ea polokeho nakong ea mosebetsi oa motlakase li ile tsa koaheloa ka botlalo.

- Ho kenya Control Software: Ho ile ha buisanoa ka ho kenya software ea taolo, calibration, le mekhoa ea liteko ho netefatsa hore mochini oa CNC o sebetsa ka nepo.

- Lubrication le Tlhokomelo: Bohlokoa ba ho tlotsa le ho lokisoa bakeng sa bophelo bo bolelele ba mochini le ts'ebetso bo ile ba totobatsoa, ho kenyeletsoa lintlha tsa ho tlotsa le linako tsa tlhokomelo.

- Mekhoa ea Tšireletso: Mekhoa ea ts'ireletso, liprothokholo tsa ho koala ha ts'ohanyetso, le ts'ebeliso ea lisebelisoa tsa ts'ireletso (PPE) li ile tsa rarolloa ho theha tikoloho e bolokehileng ea ts'ebetso.

- Ho Rarolla Mathata a Tloaelehileng a Kenyelletso: Ho ile ha fanoa ka mathata a tloaelehileng le mekhoa ea ho rarolla mathata ho thusa ho tseba le ho rarolla mathata ka katleho.

- Litlhahlobo tsa ho Qetela le Teko: Ho tsamaisa mananeo a tlhahlobo, ho netefatsa ho nepahala, le ho lokisa mochini hantle ho ile ha buisanoa ho fihlela tšebetso e nepahetseng.

- Koetliso le Ntlafatso ea Tsebo: Bohlokoa ba koetliso ea basebetsi le tlhokomelo ea basebetsi, hammoho le ntlafatso e tsoelang pele ea bokhoni, e ile ea hatisoa.

b. Bohlokoa ba ho Kenya Mochini oa CNC ka nepo

Ho kenya mochini o nepahetseng oa CNC ke motheo oo tšebetso e atlehileng ea machining e hahiloeng holim'a eona. E bohlokoa ka lebaka la mabaka a latelang:- Ho nepahala: Mochini oa CNC o kentsoeng hantle o na le monyetla oa ho hlahisa likarolo tse nepahetseng le tse nepahetseng, o fokotsa sekhechana le ho sebetsa bocha.

- Tšireletseho: Ho kenngoa ho khomarelang litekanyetso le mekhoa ea ts'ireletso ho netefatsa boiketlo ba basebetsi ba mechine le basebetsi ba tlhokomelo.

- Nako e telele: Ho kenya ts'ebetso e nepahetseng le tlhokomelo ea kamehla e lelefatsa bophelo ba mochini oa hau oa CNC, ho sireletsa matsete a hau.

- bokgoni: Mochini o kentsoeng hantle o sebetsa hantle, o fokotsa nako le ho eketsa tlhahiso.

- Quality: Boleng ba ho kenya bo ama ka ho toba boleng ba likarolo tse entsoeng ka mochine, tse lebisang ho bareki ba khotsofetseng le botumo bo ntlafetseng.

c. Ho Sheba Pele

Ha theknoloji e ntse e tsoela pele, mechini ea CNC e tla ba le bokhoni le ho feta. Ho bohlokoa ho lula u tseba ka lintlafatso tsa morao-rao, lintlafatso tsa software, le mekhoa e metle ea machining ea CNC. Ho feta moo, ha theknoloji ea CNC e ntse e fumaneha haholoanyane, liindasteri le likhoebo tse ngata li ka rua molemo melemo ea eona. Qetellong, ho kenya mochine oa CNC ke mokhoa o rarahaneng empa o khotsofatsa. Ka ho latela litataiso le mekhoa e metle e boletsoeng tataisong ena, o ka theha sethala sa ts'ebetso e atlehileng ea mochini oa CNC. Hopola hore ho tsoela pele ho ithuta, koetliso le tlhokomelo e tsoelang pele ke senotlolo sa ho boloka le ho ntlafatsa ts'ebetso ea mechine ea hau ea CNC ha u ntse u lebelletse bokamoso bo tletseng menyetla lefatšeng la tlhahiso e nepahetseng.

Services Our

- 5 selekane Machining

- Cnc siloa

- Cnc fetola

- Mechini ea Machining

- Ts'ebetso ea Machining

- Phekolo ea bokaholimo

- Metal Machining

- Machining ea polasetiki

- Phofo Metallurgy hlobo

- Ho Casting

- Likarolo tsa Gallery

Case Studies

- Likarolo tsa Auto Metal

- Likarolo tsa mechine

- Sesebelisoa sa mocheso oa LED

- Likarolo tsa Kaho

- Likarolo tsa mobile

- Likarolo tsa Bongaka

- Likarolo tsa Elektroniki

- Machining e etselitsoeng

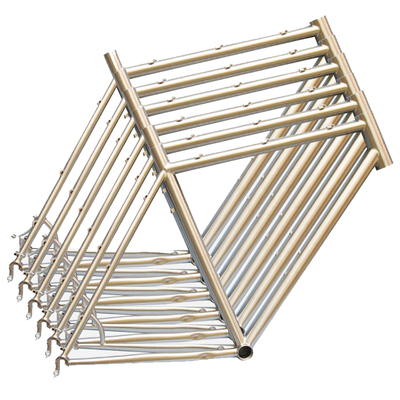

- Likarolo Tsa Baesekele

Lethathamo la lintho tse bonahalang

- Aluminium Machining

- Thaethaniamo Machining

- Lisebelisoa tsa Stainless Steel

- Koporo Machining

- Koporo Machining

- Super motsoako Machining

- Peek Machining

- Machining a UHMW

- Tlanya Machining

- Machining a PA6

- PPS Machining

- Mochini oa Teflon

- Inconel Machining

- Sesebelisoa sa Sesebelisoa sa Steel

- Boitsebiso bo Eketsehileng

Likarolo tsa Gallery