Tataiso e Felletseng ea Mefuta e fapaneng ea Lisebelisoa tsa ho Seha Lathe bakeng sa ho Fetoha, ho bora, ho shebana, ho qhekella, le lits'ebetso tse ling.

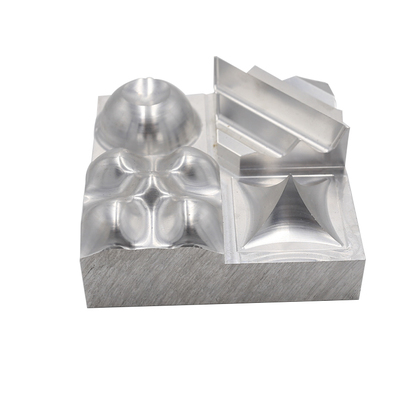

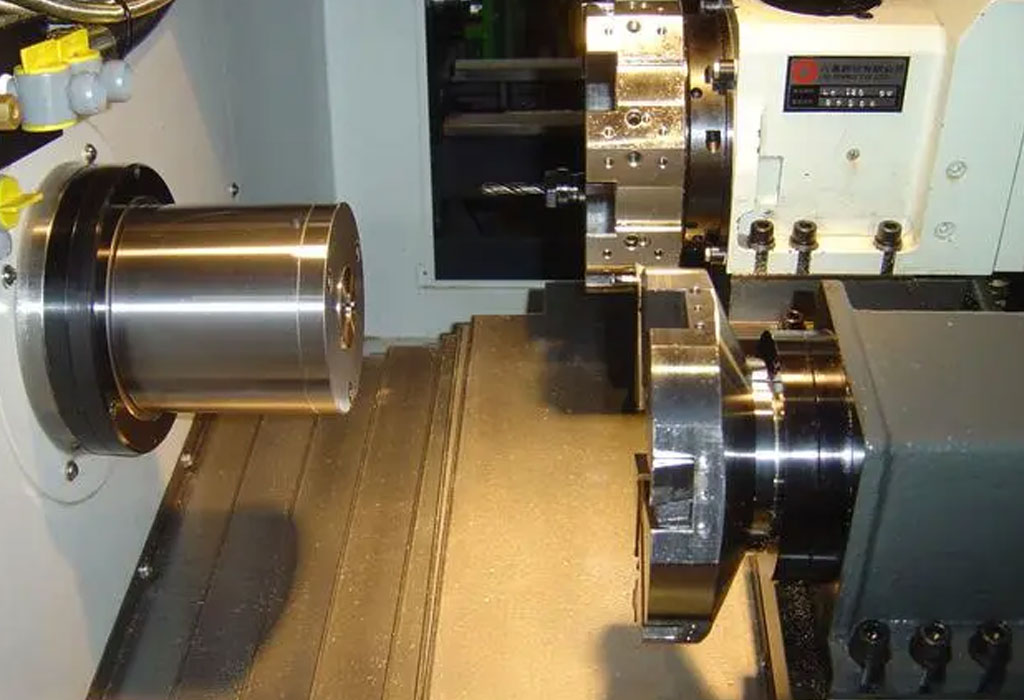

Mechini ea lathe esale e le karolo ea mantlha ea machining ka lilemo tse makholo, e nolofalletsang ho theha likarolo tse nepahetseng le tse rarahaneng tsa cylindrical. E 'ngoe ea lintlha tse ka sehloohong tse khethollang katleho ea ts'ebetso ea lathe ke khetho le tšebeliso ea lisebelisoa tsa ho itšeha. Lisebelisoa tsena li na le mefuta e mengata ea libopeho, boholo le lisebelisoa, 'me e' ngoe le e 'ngoe e etselitsoe mesebetsi e itseng e kang ho phethoha, ho bora, ho shebana, ho qhekella le tse ling. Tataisong ena e felletseng, re tla hlahloba lefats'e la lisebelisoa tsa ho itšeha, re hlahlobisisa mefuta ea tsona, litšobotsi, lits'ebetso le mekhoa e metle bakeng sa liphetho tse nepahetseng tsa mochini. Hore na u moithuti ea qalang ho batla ho ithuta lintho tsa motheo kapa setsebi sa machini se nang le boiphihlelo se batlang ho holisa tsebo ea hau, sengoloa sena se ikemiselitse ho fana ka leseli la bohlokoa lefats'eng le rarahaneng la lisebelisoa tsa ho itšeha lathe.

Karolo ea 1: Lisebelisoa tsa ho Fetola

Ts'ebetso ea ho fetolela ke lejoe la sekhutlo la mochini oa lathe, o bapala karolo ea bohlokoa ho theheng likarolo tsa cylindrical ka nepo le ho nepahala. Ts'ebetso ena e kenyelletsa ho tlosa lintho tse tsoang setsing sa mosebetsi ka ho li potoloha khahlano le sesebelisoa sa ho seha, seo hangata se hlomelloang holim'a seluloana. Ho fetoha ho bohlokoa liindastering tse fapaneng, ho kenyeletsoa likoloi, sefofane, tlhahiso le tse ling, ho etsa hore ho be bohlokoa ho utloisisa lisebelisoa tse sebelisoang ts'ebetsong. Lisebelisoa tsa ho fetola, maemong a machining a lathe, ke lisebelisoa tsa ho itšeha tse bōpang le ho hloekisa lisebelisoa tsa ho sebetsa nakong ea ho fetola. Li tla ka mefuta e mengata e fapaneng, lisebelisoa, le lijeometri ho lumellana le litlhoko le lisebelisoa tse fapaneng. Ho utloisisa bohlokoa ba lisebelisoa tsa ho fetola le mefuta ea tsona e fapaneng ho bohlokoa bakeng sa ho fihlela liphetho tse lakatsehang tsa mochini.1.2. Mefuta ea Lisebelisoa tsa ho Fetola

Lisebelisoa tsa ho fetola li fumaneha ka mefuta e mengata, e 'ngoe le e' ngoe e etselitsoe ho khotsofatsa litlhoko tse khethehileng tsa mochini. Ha re hlahlobe mekhahlelo e meng e tloaelehileng:- 1.2.1. Lisebelisoa tsa High-Speed Steel (HSS):Lisebelisoa tsa High-Speed Steel (HSS) esale e le ntho e ka sehloohong mosebetsing oa machining ka lilemo tse mashome. Li tsebahala ka ho ikamahanya le maemo, kaha li khona ho rema lisebelisuoa tse fapaneng ka katleho, ho kenyeletsoa litšepe tse nang le ferrous le tse se nang tšepe, lipolasetiki, esita le lehong. Lisebelisoa tsa HSS li ka boloka ho thatafala ha tsona le bokhoni ba ho itšeha maemong a mocheso o phahameng, ho etsa hore li tšoanelehe bakeng sa ho phethoha ka lebelo le phahameng.

- 1.2.2. Carbide Insert Tools: Lisebelisoa tsa ho kenya Carbide li se li tumme ka lebaka la ho thatafala ha tsona le ho hanyetsa ho roala. Lisebelisoa tsena li na le li-carbide tse ka nkeloang sebaka tse fanang ka likhahla tse bohale le bophelo bo atolositsoeng ba lisebelisoa. Li ntle haholo bakeng sa ho fetola lisebelisoa tse thata joalo ka tšepe e sa hloekang, ho etsa tšepe e entsoeng ka tšepe, le li-alloys tse sa tloaelehang. Lisebelisoa tsa ho kenya li-carbide hangata li sebelisoa ts'ebetsong e thata le ea ho qetela.

- 1.2.3. Lisebelisoa tsa daemane: Lisebelisoa tsa ho fetola taemane li sebelisa taemane ea maiketsetso e le lisebelisoa tsa ho seha. Litaemane li tumme ka ho thatafala ha tsona, tse lumellang sebetsa ka ho nepahetseng machining ea lisebelisoa tse thata haholo joalo ka ceramic le khalase. Lisebelisoa tsa daemane li nepahetse bakeng sa lits'ebetso tse hlokang pheletso e phahameng ea bokaholimo le ho nepahala ha boholo.

- 1.2.4. Cermet Tools: Lisebelisoa tsa Cermet ke lebasetere la li-ceramics le litšepe, tse fanang ka tekano pakeng tsa boima le boima. Li loketse hantle bakeng sa ho lokisa li-alloys tse nang le mocheso o phahameng le litšepe tse thata. Lisebelisoa tsa Cermet li ipabola lits'ebetsong tsa machining tse lebelo le holimo, moo li ka mamellang mocheso o phahameng le ho boloka ts'ebetso ea tsona ea ho itšeha.

- 1.2.5. Lisebelisoa tsa Cubic Boron Nitride (CBN): Lisebelisoa tsa Cubic Boron Nitride (CBN) ke tse ling tsa lisebelisoa tse thata ka ho fetisisa tsa ho itšeha tse fumanehang, tsa bobeli ho tsa daemane. Li loketse ho etsa litšepe tse thata le li-superalloys. Lisebelisoa tsa CBN li fana ka khanyetso e ikhethang ea ho roala, e li etsang hore li tšoanelehe bakeng sa likheo tse tsoelang pele le tse sitisang lisebelisoa tse thata.

1.3. Ho Khetha Sesebelisoa sa ho Fetola se nepahetseng

Ho khetha sesebelisoa se nepahetseng sa ho fetola ke qeto ea bohlokoa e susumetsang katleho ea ts'ebetso ea mochini. Mona ke lintlha tsa bohlokoa tse lokelang ho nahanoa ha u khetha sesebelisoa sa ho fetola:- 1.3.1. Tšebelisano ea lintho tse bonahalang: Thepa ea workpiece ke ntlha ea bohlokoa khethong ea lisebelisoa. Lisebelisoa tse fapaneng li na le ho thatafala ho fapaneng, abrasiveness le conductivity ea mocheso. Etsa bonnete ba hore sesebelisoa se khethiloeng se lumellana le lisebelisoa tsa mosebetsi ho thibela ho roala pele ho nako kapa ho hlōleha ha lisebelisoa.

- 1.3.2. Tool Geometry: Geometry ea sesebelisoa, ho kenyelletsa sebopeho sa eona, angle angle, le li-angles tse hlakileng, li ama ts'ebetso ea ho itšeha haholo. Nahana ka litlhoko tse khethehileng tsa ts'ebetso ea ho fetola, joalo ka ho phunya kapa ho qeta, 'me u khethe sesebelisoa se nang le geometry e nepahetseng ho ntlafatsa sephetho.

1.4. Malebela a ho Phetla ka Katleho

Ho finyella ts'ebetso e atlehileng ea ho fetola ho hloka tlhokomelo ho lintlha le ho nepahala. Mona ke malebela a bohlokoa a ho ntlafatsa katleho ea lisebelisoa tsa ho fetola:- 1.4.1. Tlhophiso e Nepahetseng ea Sesebelisoa: Netefatsa hore sesebelisoa se kentsoe ka mokhoa o sireletsehileng 'me se hokahantsoe ka nepo posong ea sesebelisoa sa lathe. Ho se lumellane hofe kapa hofe ho ka lebisa ho senyeha ha bokaholimo, ho eketsa lisebelisoa tsa lisebelisoa, le ho fokotsa ho nepahala.

- 1.4.2. Machining Parameters le Surface Qetella Menahano: Fetola litekanyo tsa ho itšeha joalo ka lebelo la ho itšeha, sekhahla sa phepelo, le botebo ba sehiloeng ho latela thepa ea mosebetsi le mofuta oa sesebelisoa. Laola liparamente tsena ka hloko ho fihlela sephetho se lakatsehang sa bokaholimo, ho nepahala ha sebopeho, le ho tlosoa ha chip.

Karolo ea 2: Lisebelisoa tsa Boring

2.1. Selelekela ho Lisebelisoa tsa Boring

Mesebetsi ea boring ke ea bohlokoa ho ts'ebetso ea machininges, e lumellang katoloso e nepahetseng kapa ntlafatso ea likoti tse teng ho li-workpieces. Hore na e theha masoba a boholo bo nepahetseng ka har'a li-block tsa enjine kapa ho fumana mamello e tiileng likarolong tsa cylindrical, lisebelisoa tse tenang li bohlokoa haholo liindastering tse fapaneng. Karolong ena, re tla shebana le lefats'e la lisebelisoa tse tenang tse sebelisoang mochining oa lathe. Lisebelisoa tsa boring, joalo ka ha lebitso le fana ka maikutlo, li etselitsoe ho phunya masoba ka nepo e phahameng. Li bohlokoa haholo ha mekhoa e tloaelehileng ea ho cheka e sa lekana kapa ha lesoba le hloka ho tsamaisana hantle le tšobotsi e teng. Ho utloisisa bohlokoa ba ts'ebetso e tenang le ho fumana leseli mabapi le mefuta ea lisebelisoa tse tenang tse fumanehang ho bohlokoa bakeng sa ho fihlela sephetho se nepahetseng sa mochini.2.2. Mefuta ea Lisebelisoa tsa Boring

Lisebelisoa tsa boring li kenyelletsa mefuta e mengata ea lisebelisoa tse ikhethileng, e 'ngoe le e' ngoe e etselitsoe lits'ebetso tse ikhethileng. Ha re hlahlobeng likarolo tse ling tse tloaelehileng tsa lisebelisoa tse tenang:- 2.2.1. Li-Boring Bars: Li-bar tsa boring li sebetsa ka mokhoa o fapaneng 'me li sebelisoa haholo machining a lathe. Lisebelisoa tsena tse tšesaane, tse telele li khona ho fihla botebong ba lisebelisoa ho phunya masoba ka nepo. Li-bar tsa boring li ka amohela mefuta e fapaneng ea ho kenya, ho li etsa hore li tšoanelehe bakeng sa ts'ebetso e thata le ea ho qeta.

- 2.2.2. Lihlooho tse Boring: Lihlooho tse borehang li fana ka phetoho e kholo mabapi le ho lokisa bophara ba bore. Li na le 'mele o nang le sesebelisoa sa ho itšeha le mochini oa liphetoho tse ntseng li eketseha. Sena se lumella bo-machini ho laola ka nepo boholo ba bore nakong ea ts'ebetso ea mochini.

- 2.2.3. Lisebelisoa tsa ho Rata le ho Qetella: Maemong a mang, ts'ebetso e tenang e arotsoe ka mekhahlelo e 'meli: e thata le ea ho qeta. Lisebelisoa tse hlabang tse tenang li etselitsoe ho tlosoa ha thepa ka litheko tse phahameng tsa phepelo, ha lisebelisoa tse phetheselang tse tenang li fana ka ho nepahala le pheletso e hlokahalang. Ho sebelisa motsoako oa lisebelisoa tsena ho fana ka ts'ebetso e sebetsang hantle le e nepahetseng e tenang.

2.3. Ho khetha Sesebelisoa se nepahetseng sa Boring

Ho khetha sesebelisoa se nepahetseng sa boring ke sa bohlokoa bakeng sa ho fihlela litholoana tse atlehileng tsa mochini. Lintlha tse 'maloa li susumetsa khetho ea sesebelisoa se borang:2.3.1. Lintlha tse Susumetsang Khetho ea Sesebelisoa sa Boring

- Lisebelisoa tsa Workpiece: Thepa e ntseng e etsoa e ama haholo khetho ea lisebelisoa. Lisebelisoa tse thata li ka 'na tsa hloka lisebelisoa tse khethehileng tse nang le li-carbide, ha lisebelisoa tse bonolo li ka etsoa ka katleho ka lisebelisoa tsa tšepe tse phahameng ka potlako (HSS).

- Boholo ba Hole le Mamello: Boholo bo lakatsehang ba bore le ho tiea ha mamello li laela khetho ea sesebelisoa se bora. Lihlooho tse boring hangata li ratoa ha taolo e nepahetseng holim'a bophara ba bore e hlokahala.

- Botebo ba Sekoti: Botebo ba lesoba bo susumetsa khetho ea sesebelisoa, kaha libore tse telele li ka hloka mekoallo e tenang e nang le phihlello e atolositsoeng.

- Maemo a Machining: Nahana ka tikoloho ea mochini, joalo ka hore na ke lesela la CNC kapa lathe ea letsoho, hammoho le mokelikeli o teng oa ho itšeha le lisebelisoa tse pholisang.

2.3.2. Litefiso tsa ho Tlosa Lintho le Liphetoho tsa Lisebelisoa

Ho ntlafatsa ts'ebetso e tenang, ho bohlokoa ho beha maemo a nepahetseng a ho itšeha, ho kenyelletsa lebelo la ho itšeha, sekhahla sa phepelo le botebo ba sehiloeng. Litokiso ho li-parameter tsena li lokela ho etsoa ho ipapisitse le lisebelisoa tsa mosebetsi le sesebelisoa se khethiloeng sa bora. Ho leka-lekanya ka nepo litekanyetso tsa ho tlosoa ha thepa ka litokiso tsa lisebelisoa ho netefatsa ho sebetsa hantle ntle le ho senya ho nepahala.2.4. Mekhoa e Molemo ka ho Fetisisa ea Boring e Atlehang

Ho fumana ho nepahala le ho boloka mamello e tiileng ts'ebetsong e tenang ho hloka tlhokomelo e hlokolosi ea mekhoa e metle. Litlhahiso tse ling tsa bohlokoa ke tsena:- 2.4.1. Tool Setup le Workpiece Clamping: Netefatsa hore sesebelisoa se borang se behiloe ka mokhoa o sireletsehileng 'me se hokahane le mosebetsi. Ho hlophisa lisebelisoa hantle ho fokotsa ho thothomela le ho ntlafatsa botsitso ba ho itšeha. Sireletsehile workpiece clamping ke ka tsela e tšoanang bohlokoa ho thibela ho sisinyeha nakong tshebetso machining.

- 2.4.2. Ho Finyella Mamello e Matla le ho Felisoa ha Bokahohle: Ho fihlela mamello e tiileng, etsa liphetoho tse ntseng li eketseha ho sesebelisoa se borang ha u ntse u lekola boholo ba bore ka lisebelisoa tsa ho lekanya tse nepahetseng. Ka linako tsohle hlahloba le ho boloka bohale ba ho itšeha ho etsa bonnete ba hore ho na le boleng ba boleng bo holimo le bo nepahetseng.

Karolo ea 3: Ho tobana le Lisebelisoa

3.1. Selelekela ho Facing Tools

Ho sebetsana le ts'ebetso ea mochini oa lathe ho bohlokoa bakeng sa ho theha libaka tse bataletseng le tse boreleli lipheletsong tsa li-cylindrical workpieces. Hore na e squaring up lipheletsong tsa a theko kapa ho netefatsa sebaka se nepahetseng sa ho nyalana bakeng sa likarolo, ho shebana le mokhoa o tloaelehileng le oa bohlokoa oa machining. Karolong ena, re tla hlahloba karolo ea ho sebetsana le ts'ebetso le ho kenella lefats'eng la lisebelisoa tse shebaneng le lisebelisoa tse sebelisoang mochining oa lathe. Lisebelisoa tsa ho shebana, joalo ka ha lebitso la tsona le bolela, ke lisebelisoa tse khethehileng tse etselitsoeng ho etsa ts'ebetso e shebaneng hantle. Li thusa bo-machini ho tlosa thepa ka ho lekana ho tloha qetellong ea mosebetsi, ho fella ka sebaka se bataletseng le se boreleli. Ho utloisisa bohlokoa ba ho sebetsana le ts'ebetso le ho fumana leseli mabapi le mefuta ea lisebelisoa tse shebaneng le tsona ke tsa bohlokoa bakeng sa ho fumana liphetho tse nepahetseng le tse khahlisang tsa mochini.3.2. Mefuta ea lisebelisoa tsa ho shebana

Lisebelisoa tse sebetsanang le tsona li tla ka mefuta e fapaneng, e 'ngoe le e' ngoe e etselitsoe litlhoko tse tobileng tse tobaneng le tsona. A re hlahlobeng tse ling tsa mekhahlelo e tloaelehileng ea lisebelisoa tse sebetsanang le tsona:- 3.2.1. Facing Mills: Li-mill tse shebaneng le tsona ke lisebelisoa tsa ho seha tse etselitsoeng ts'ebetso e shebaneng le lebelo le holimo. Ka tloaelo li na le likarolo tse ngata tsa ho itšeha kapa tse kentsoeng, tse lumellang ho tlosoa ha thepa hantle. Li-mill tse shebaneng le tsona li na le mefuta e mengata ebile li loketse lisebelisoa tse fapaneng tsa mosebetsi, ho kenyeletsoa litšepe le polasetiki.

- 3.2.2. Lisebelisoa tsa ho Face Grooving: Lisebelisoa tsa ho phunya sefahleho li ikhethile bakeng sa ho theha li-grooves kapa likheo sefahlehong sa mosebetsi. Lisebelisoa tsena li ka sebelisoa bakeng sa lits'ebetso tse kang O-ring grooves kapa machining a khabisitsoeng. Lisebelisoa tsa ho roala sefahleho li fumaneha ka li-geometri tse fapaneng ho amohela lintlha tse ikhethang tsa groove.

- 3.2.3. Lihlooho tse Boring bakeng sa ho Tobana: Lihlooho tse boring, joalo ka ha ho boletsoe karolong e fetileng, le tsona li ka sebelisoa bakeng sa ts'ebetso e shebaneng le ha ho hlokahala taolo e nepahetseng holim'a bokaholimo bo felileng. Li lumella litokiso tse ntseng li eketseha botebong ba sehiloeng, ho netefatsa liphetho tse nepahetseng tse shebaneng le tsona.

3.3. Ho Khetha Sesebediswa sa Sefahleho se Nepahetseng

Ho bohlokoa ho khetha sesebelisoa se nepahetseng bakeng sa ho etsa ts'ebetso e nepahetseng. Lintlha tse 'maloa li susumetsa khetho ea sesebelisoa se shebaneng: 3.3.1. Geometry ea Mosebetsi le Menahano ea Lintho: Nahana ka sebopeho le boholo ba sesebelisoa sa mosebetsi, hammoho le thepa ea sona ea thepa. Lisebelisoa tse fapaneng tse shebaneng li ka ba tse loketseng haholoanyane bakeng sa lisebelisoa tse bataletseng, tsa cylindrical, kapa tse nang le sebopeho se sa tloaelehang. Ho phaella moo, lisebelisoa tse ling li ka 'na tsa hloka lisebelisoa tse khethehileng tsa lisebelisoa kapa liaparo ho finyella liphello tse ntle. 3.3.2. Litlhokahalo tsa Surface Finish le Khetho ea Lisebelisoa: Sephetho se lakatsehang se bapala karolo ea bohlokoa khethong ea lisebelisoa. Bakeng sa lisebelisoa tsa boleng bo phahameng ba holimo, lisebelisoa tse nang le likhahla tse bohale le bokhoni ba ho etsa liphetoho tse ntle li khethoa. Ka mohlala, lihlooho tse boring li fana ka taolo e nepahetseng holim'a bokaholimo ka lebaka la liphetoho tse ntseng li eketseha.3.4. Mekhoa ea Bohlokoa ea ho Talimana ka Katleho

Ho fumana katleho ha o sebetsana le ts'ebetso ho hloka ho ela hloko lintlha le ho nepahala. Mona ke mekhoa e meng ea bohlokoa ea ho sebetsana ka katleho le bothata:- 3.4.1. Tool Positioning and Alignment: Beha ka nepo 'me u ikamahanye le sesebelisoa se shebaneng le mosebetsi ho netefatsa hore ho tlosoa ha thepa le sebaka se bataletseng, se boreleli. Ho se tsamaisane hantle ho ka baka ho se hlophisehe ha holimo le liphello tse mpe.

- 3.4.2. Ho shebana le lisebelisoa tse fapaneng le libopeho tsa mosebetsi: Ha u shebane le lisebelisoa tse fapaneng, fetola maemo a ho itšeha joalo ka lebelo la ho itšeha, sekhahla sa phepelo le botebo ba sehiloeng. Ela hloko sebopeho sa workpiece 'me u nahane hore na sesebelisoa se khethiloeng se loketse geometry e khethehileng, haholo-holo ha u tobane le likarolo tse sa tloaelehang.

Karolo ea 4: Lisebelisoa tsa Chamfering le Thread Cutting

4.1. Selelekela sa Chamfering le Thread Cutting

Chamfering le khoele ea ho kuta ke mekhoa ea bohlokoa ea machining e sebetsang mesebetsi ea bohlokoa liindastering tse fapaneng. Chamfering e kenyelletsa ho koala mathōko a masoba, mathōko, kapa bokaholimo ba mosebetsi, ho ntlafatsa ho tšoarella ha tsona, botle ba tsona le polokeho. Ho khaola likhoele ke mokhoa oa ho theha likhoele tsa screw holim'a li-cylindrical workpieces, tse nolofalletsang ho kopanya likarolo kapa ho fana ka mokhoa oa ho tiisa. Karolong ena, re tla hlahloba bohlokoa ba ho chamfering le ho seha likhoele ka machining a lathe le ho hlahisa lisebelisoa tse sebelisetsoang ts'ebetso ena. Lisebelisoa tsa chamfering le likhoele ke lisebelisoa tse khethehileng tse etselitsoeng ho etsa mesebetsi ena ka nepo le ka bokhabane. Ho utloisisa bohlokoa ba tsona le mefuta ea lisebelisoa tse teng ho bohlokoa bakeng sa ho fihlela sephetho se lakatsehang sa mochini.4.2. Mefuta ea Lisebelisoa tsa Chamfering le Thread Cutting

Lisebelisoa tsa chamfering le likhoele li kenyelletsa mekhahlelo e fapaneng, e 'ngoe le e' ngoe e etselitsoe litlhoko tse ikhethileng tsa mochini. A re ke re hlahlobeng mefuta e meng e tloaelehileng ea lisebelisoa tsena:- 4.2.1. Lisebelisoa tsa Chamfering: Lisebelisoa tsa Chamfering, tse tsejoang hape e le li-mill tsa chamfer kapa li-countersinks, li etselitsoe ho theha maqheka a beveled holim'a lisebelisoa tsa mosebetsi. Li tla ka libopeho le boholo bo fapaneng, tse lumellang bo-machini ho phunya masoba, mathōko kapa bokaholimo. Lisebelisoa tsa Chamfering li ntlafatsa botle le ts'ebetso ea sesebediswa, li fokotsa likarolo tse bohale, 'me li ntlafatsa kopano.

- 4.2.2. Lisebelisoa tsa ho Seha likhoele: Lisebelisoa tsa ho seha likhoele li bohlokoa bakeng sa ho theha likhoele tsa screw holim'a li-cylindrical workpieces. Li tla ka mefuta e fapaneng, ho kenyelletsa le lipompo tsa likhoele tse ka hare 'me li shoela likhoele tsa kantle. Lisebelisoa tsa ho seha likhoele li teng bakeng sa mefuta e fapaneng ea likhoele le li-pitches, e leng se etsang hore li fetohe bakeng sa lits'ebetso tse fapaneng.

- 4.2.3. Lisebelisoa tsa ho lelekisa likhoele: Lisebelisoa tsa ho lelekisa likhoele, tseo hangata ho thoeng ke li-thread chaser, li sebelisetsoa ho lokisa kapa ho khutlisetsa likhoele tse senyehileng holim'a lisebelisoa tsa mosebetsi. Hangata li sebelisoa ha likhoele tsa pele li koaheloa kapa li senyehile, ho etsa bonnete ba hore li lekana hantle bakeng sa likarolo tse lohiloeng. Lisebelisoa tsa ho lelekisa likhoele li tla ka meralo e fapaneng ho tsamaisana le li-profiles le boholo bo itseng ba likhoele.

- 4.3. Ho Khetha Sesebelisoa se nepahetseng bakeng sa Chamfering le Thread Cutting

- 4.3.1. Mehopolo ea Angle le Boholo: Bakeng sa lisebelisoa tse hohelang, angle ea chamfer e lakatsehang le boholo ba sesebediswa sa mosebetsi li khetha khetho ea sesebelisoa. Li-angles tse fapaneng li sebeletsa merero e fapaneng, joalo ka li-chamfer tsa 45-degree bakeng sa tšebeliso e akaretsang kapa li-chamfer tsa 90-degree bakeng sa ho theha li-angles tse nepahetseng.

- 4.3.2. Mefuta ea likhoele le Khetho ea Pitch: Ha u khetha lisebelisoa tsa ho seha likhoele, nahana ka mofuta oa khoele (mohlala, metric kapa e kopaneng) le molumo o hlokahalang oa khoele. Ho bapisa sesebelisoa le mofuta o itseng oa khoele ho netefatsa liprofaele tse nepahetseng tsa khoele le likhoele tse nepahetseng.

4.4. Mekhoa e nepahetseng bakeng sa Chamfering le Thread Cutting

Ho finyella ho nepahala ha chamfering le khoele, ho bohlokoa ho latela mekhoa le mekhoa e metle. Mona ke lintlha tse ling tsa bohlokoa:- 4.4.1. Tlhophiso e nepahetseng ea lisebelisoa le ho tsamaisana: Netefatsa hore sesebelisoa sa chamfering kapa khoele se behiloe ka mokhoa o sireletsehileng 'me se tsamaisana le sesebedisoa. Ho se nepahale ho ka lebisa ho se nepahaleng le liphello tse mpe. Ho feta moo, boloka lisebelisoa tse nepahetseng le ho fetella ho qoba ho kena-kenana le lisebelisoa.

- 4.4.2. Ho Finyella Liprofaele tse Nepahetseng tsa Khoele le Li-Angles tsa Chamfer: Bakeng sa ho seha likhoele, hlokomela botebo ba khoele, molumo le profil ka hloko. Sebelisa lisebelisoa tsa ho metha ka nepo ho netefatsa hore likhoele li kopana le lintlha tse batloang. Ha u checha, netefatsa sekhutlo le boholo ba chamfer u sebelisa lisebelisoa tse nepahetseng tsa ho lekanya ho fihlela pheletso le ts'ebetso eo u e batlang.

Karolo ea 5: Lisebelisoa tsa Grooving le Karohano

5.1. Kenyelletso ea Lisebelisoa tsa Grooving le Karohano

Ts'ebetso ea grooving le ea karohano ke ea bohlokoa bakeng sa machining a lathe, a sebeletsa karolo ea bohlokoa ho thehoeng ha likarolo tse nepahetseng. Grooving e kenyelletsa ho seha likheo kapa likanale ka har'a sesebelisoa, hangata ka merero e kang ho amohela li-O-rings, mehele ea ho boloka, kapa likarolo tsa mokhabiso. Ka lehlakoreng le leng, karohano ke mokhoa oa ho khaola sesebedisoa ka likotoana tse arohaneng kapa ho tlosa likarolo tse sa batleheng. Karolong ena, re tla hlahloba bohlokoa ba ts'ebetso ea grooving le karohano le ho hlahisa lisebelisoa tse sebelisetsoang mesebetsi ena ho machining a lathe. Lisebelisoa tsa grooving le ho arohana ke lisebelisoa tse khethehileng tse etselitsoeng ho etsa ts'ebetso ena ka katleho. Ho bohlokoa ho utloisisa bohlokoa ba tsona le ho fumana leseli mabapi le mefuta ea lisebelisoa tse teng bakeng sa ho fumana liphetho tse nepahetseng tsa mochini.5.2. Mefuta ea Lisebelisoa tsa Grooving le Karohano

Lisebelisoa tsa grooving le karohano li kenyelletsa mekhahlelo e fapaneng, e 'ngoe le e' ngoe e etselitsoe litlhoko tse ikhethileng tsa mochini. A re ke re hlahlobeng mefuta e meng e tloaelehileng ea lisebelisoa tsena:- 5.2.1. Lisebelisoa tsa karohano: Lisebelisoa tsa karohano, tse tsejoang hape e le lisebelisoa tse khaotsoeng, li etselitsoe ka ho khetheha ho arola sekhechana sa mosebetsi likotoana tse peli kapa ho feta. Li na le sehatsetsi se sehang 'me li fumaneha ka libopeho le boholo bo fapaneng. Lisebelisoa tsa karohano li sebelisoa bakeng sa lits'ebetso tse joalo ka ho khaola karolo ea molamu kapa ho theha likarolo tse ikhethileng ho tsoa ho sesebelisoa se le seng.

- 5.2.2. Lisebelisoa tsa Grooving: Lisebelisoa tsa grooving li sebelisetsoa ho etsa liteishene, li-recesses kapa li-grooves holim'a sebaka sa mosebetsi. Lisebelisoa tsena li tla ka li-geometri tse fapaneng ho amohela lintlha tse ikhethang tsa groove. Lisebelisoa tsa grooving li sebetsa ka mokhoa o fapaneng 'me li ka sebelisoa bakeng sa lits'ebetso tse kang ho theha litsela tsa bohlokoa, lipaterone tsa mekhabiso, kapa likarolo tsa ho boloka.

- 5.2.3. Lisebelisoa tsa ho Feta le ho Khaoha: Lits'ebetso tse ling tsa lisebelisoa tsa lathe li sebelisa li-threading le li-cut-off tse kenyang ts'ebetso ea ho kopanya le ho arola. Lisebelisoa tsena li etselitsoe ho hlahisa likhoele ka nepo le ho khaola li-workpieces ka mokhoa o hloekileng. Li fumaneha ka boholo bo fapaneng le li-profile tsa khoele ho lumellana le litlhoko tse khethehileng.

5.3. Ho Khetha Sesebelisoa se Nepahetseng sa Grooving le Karohano

Ho khetha sesebelisoa se nepahetseng sa grooving kapa ho arohana ho bohlokoa bakeng sa ho fihlela litholoana tse atlehileng tsa machining. Lintlha tse 'maloa li susumetsa khetho ea lisebelisoa:- 5.3.1. Bophara, Botebo, le Boitsebiso ba Lintho: Nahana ka bophara bo hlokahalang le botebo ba groove ha u khetha lisebelisoa tsa grooving. Ho feta moo, thepa ea workpiece e susumetsa khetho ea lisebelisoa le ho roala, kaha lisebelisoa tse thata li ka hloka lisebelisoa tse khethehileng bakeng sa ho itšeha hantle.

- 5.3.2. Tool Geometry le Clearance Angles: Geometry ea sesebelisoa, ho kenyelletsa le angle angle, clearance angles, le cutting edge geometry, e phetha karolo ea bohlokoa khethong ea lisebelisoa. Geometry e nepahetseng ea sesebelisoa e netefatsa phallo e sebetsang ea chip, e fokotsa matla a ho itšeha, le bophelo bo atolositsoeng ba lisebelisoa.

5.4. Mekhoa e Sebetsang bakeng sa Grooving le karohano

Ho fumana katleho ts'ebetsong ea grooving le karohano ho hloka hore ho nahanoe ka hloko mekhoa le mekhoa e metle. Mona ke lintlha tsa bohlokoa:- 5.4.1. Sebaka sa Mosebetsi: Ho koala sekhechana sa mosebetsi ho bohlokoa ho thibela ho sisinyeha le ho netefatsa hore sesebelisoa sa mosebetsi se lula se le sebakeng se sireletsehileng nakong ea grooving kapa karohano. Ho beha lisebelisoa ka nepo ho bohlokoa ka mokhoa o ts'oanang ho fihlela sephetho se hloekileng le se nepahetseng.

- 5.4.2. Ho Finyella Liphetho tse Hloekileng tsa Karohano le Mehopolo: Boloka litekanyo tse nepahetseng tsa ho itšeha, joalo ka lebelo la ho itšeha, sekhahla sa phepelo, le botebo ba ho seha, ho etsa bonnete ba hore li-chips li tsoa hantle le ho roala lisebelisoa tse fokolang. Netefatsa hore sesebediswa se sehang se nchocho, 'me u sebelise setaele se nepahetseng ho fumana li-grooves tse hloekileng le tse nepahetseng kapa mela e arohaneng.

fihlela qeto e

Tataisong ena e felletseng, re hlahlobile mefuta e mengata ea lisebelisoa tsa ho itšeha tse sebelisoang lits'ebetsong tse fapaneng, tse kenyelletsang ho phethoha, ho bora, ho shebana, ho roala likhoele, ho kuta le ho arola. Lisebelisoa tsena li bapala karolo ea bohlokoa lefats'eng la machining a lathe, ho lumella bo-machini ho theha likarolo tse nepahetseng le tse rarahaneng ho pholletsa le liindasteri tse fapaneng. Karolo e 'ngoe le e' ngoe ea tataiso ena e fane ka lintlha tsa bohlokoa mabapi le bohlokoa ba ts'ebetso e khethehileng ea machining le ho hlahisa mefuta ea lisebelisoa tsa ho itšeha tse sebelisoang hangata. Re buisane ka lintlha tse susumetsang khetho ea lisebelisoa, bohlokoa ba ho lumellana ha thepa, le karolo ea geometry ea lisebelisoa le mekhoa ea ho itšeha ho fihlela sephetho se nepahetseng. Sengoliloeng sena sohle, re hatelletse bohlokoa ba ho nepahala, ho seta lisebelisoa ka nepo, ho loants'a, le ho latela mekhoa e metle bakeng sa ho sebetsa ka mokhoa o atlehileng oa lathe. Hore na o moithuti ea qalang ho ithuta lintho tsa motheo kapa setsebi sa machini se nang le boiphihlelo se batlang ho holisa tsebo ea hau, tlhaiso-leseling e hlahisitsoeng mona e sebetsa e le sesebelisoa sa bohlokoa sa ho u thusa ho u thusa ho ntlafatsa tsebo ea hau ea ho sebetsa. Ha thekenoloji e ntse e tsoela pele, lefats'e la lisebelisoa tsa ho itšeha le ntse le le matla ebile le lula le fetoha, le fana ka menyetla e mecha ea ho qapa le ho nepahala ha ho etsoa. Hore na ua reteleha, ua bora, ua shebana, ua thakhisa, ua thaepa, ua phunya kapa ua arohana, tsebo e fanoeng tataisong ena e u hlomella ka lintlha tsa motheo tse hlokahalang ho ipabola bocheng ba lathe. Hopola hore khetho ea sesebelisoa se nepahetseng sa ho itšeha le ho sebelisa mekhoa e nepahetseng hangata ke linotlolo tsa katleho ho machining a lathe. Ho tsoela pele ho ntlafatsa tsebo ea hau, ho lula u le morao-rao ka tsoelo-pele ea lisebelisoa, le ho amohela bonono le mahlale a machining a lathe ntle le pelaelo ho tla lebisa ho thehoeng ha likarolo tse ikhethang ka boiketlo le botsitso. Ha u ntse u kena leetong la hau la mochini oa lathe kapa u batla ho ntlafatsa tsebo ea hau e teng, e se eka tataiso ena e felletseng e ka sebetsa e le setšupiso sa bohlokoa le mohloli oa ts'usumetso, e u nolofalletsang ho notlolla bokhoni bo felletseng ba mochini oa hau oa lathe le ho fihlela litholoana tse makatsang mesebetsing ea hau ea ho sebetsa. .

- 5 selekane Machining

- Cnc siloa

- Cnc fetola

- Mechini ea Machining

- Ts'ebetso ea Machining

- Phekolo ea bokaholimo

- Metal Machining

- Machining ea polasetiki

- Phofo Metallurgy hlobo

- Ho Casting

- Likarolo tsa Gallery

- Likarolo tsa Auto Metal

- Likarolo tsa mechine

- Sesebelisoa sa mocheso oa LED

- Likarolo tsa Kaho

- Likarolo tsa mobile

- Likarolo tsa Bongaka

- Likarolo tsa Elektroniki

- Machining e etselitsoeng

- Likarolo Tsa Baesekele

- Aluminium Machining

- Thaethaniamo Machining

- Lisebelisoa tsa Stainless Steel

- Koporo Machining

- Koporo Machining

- Super motsoako Machining

- Peek Machining

- Machining a UHMW

- Tlanya Machining

- Machining a PA6

- PPS Machining

- Mochini oa Teflon

- Inconel Machining

- Sesebelisoa sa Sesebelisoa sa Steel

- Boitsebiso bo Eketsehileng