Tlhahlobo e Felletseng ea Hard Chrome Plating vs. Decorative Chrome Plating

Chrome plating ke mokhoa o sebelisoang haholo oa ho qeta bokaholimo o ntlafatsang ponahalo le ho tšoarella ha lisebelisoa tse fapaneng. Mefuta e 'meli e tloaelehileng ea ho roala ka chrome ke plating ea chrome e thata le ho khabisa ka chrome. Leha ba arolelana ts'ebetso e ts'oanang ea mantlha, ts'ebeliso ea bona, litšoaneleho le merero li fapana haholo. Sehloohong sena, re tla hlahlobisisa lintlha tsa ho roala chrome ka thata le ho khabisa ka chrome, ho totobatsa phapang le ts'ebeliso ea bona.

Hard Chrome Plating:

-

Morero: Hard chrome plating, eo hape e tsejoang ka hore ke indasteri ea chrome plating, e sebelisoa haholo ho matlafatsa ts'ebetso ea ho hanyetsa, ho hanyetsa kutu, le ho thatafala ha bokaholimo. E atisa ho sebelisoa lits'ebetsong tsa indasteri moo ho tšoarella le ho sebetsa ho leng bohlokoa.

-

Botenya: Ho roala ha chrome ka thata hangata ho fella ka mokhabiso o motenya ha o bapisoa le oa ho khabisa oa chrome. Botenya bo ka tloha ho 0.002 ho isa ho 0.02 inches, ho fana ka lera le tiileng le le tšoarellang.

-

Substrates: Hard chrome plating e loketse li-substrates tse fapaneng, ho kenyeletsoa tšepe, aluminium le litšepe tse ling. E atisa ho khethoa bakeng sa likarolo tse tlas'a ts'ebetso e boima le ho taboha, joalo ka lithupa tsa hydraulic, pistons le mechine ea indasteri.

-

Ponahalo: Ponahalo ea "chrome plating" e thata ka kakaretso ha e khahlise ha e bapisoa le chrome e khabisitsoeng. E atisa ho ba le qetello ea matte kapa satin, e tsepamisitseng maikutlo ho feta ts'ebetsong ho feta boipiletso ba pono.

-

Tshebetso: Ts'ebetso e thata ea chrome plating e kenyelletsa ho sebelisa lera la chromium ho substrate ka mokhoa oa electroplating. Sena se fella ka sebaka se thata le se tšoarellang se khonang ho mamella maemo a thata.

Mokhabiso oa Chrome Plating:

-

Morero: Mokhabiso oa chrome plating o sebelisoa haholo ho ntlafatsa bokhabane ba bokaholimo. Hangata e fumanoa likarolong tsa likoloi, malapeng lihlopha, le thepa e fapaneng ea bareki moo ho batloang qetello e benyang le e khahlehang.

-

Botenya: Ho khabisa ka chrome ho etsa hore ho be le seaparo se sesesaane ha se bapisoa le sekontiri se thata sa chrome. Botenya hangata bo tloha ho 0.0002 ho isa ho 0.002 inches, bo fana ka lera le benyang le le khahlang ka pono.

-

Substrates: Mokhabiso oa chrome plating hangata o sebelisoa ho lisebelisoa tse kang koporo, zinki, le polasetiki, ho phaella ho litšepe tse kang tšepe le aluminium. Ho feto-fetoha hona ho etsa hore e loketse mefuta e mengata ea lihlahisoa tsa bareki.

-

Ponahalo: Tšobotsi e hlahelletseng ea ho khabisa ka chrome ke chebahalo ea eona e khanyang haholo le e benyang. Hangata qetello e tšoana le seipone, e tlatsetsang ho botle ba kakaretso ba ntho e koahetsoeng.

-

Ts'ebetso: Mokhoa oa ho khabisa ka chrome o ts'oana le plating e thata ea chrome, e kenyelletsang ts'ebetso ea electroplating. Leha ho le joalo, ho hatisoa ho finyella bokaholimo bo boreleli le bo benyang ho e-na le ho ba le thepa ea ts'ebetso.

Qetello: Ka bokhuts'oane, le hoja ho roala ka chrome ka thata le ho khabisa ka chrome ho kenyelletsa electroplating ea chromium holim'a li-substrates, merero le litšobotsi tsa tsona li fapane haholo. Hard chrome plating ke LisebelisoaE etselitsoe ho tšoarella le ho sebetsa hantle, e nang le moalo o motenya le sephetho sa matte, ha mokhabiso oa chrome o shebane le botle bo botle, o fana ka pheletso e mosesaane, e benyang. Ho utloisisa liphapang tsena ho bohlokoa bakeng sa ho khetha mokhoa o nepahetseng oa ho roala chrome ho latela ts'ebeliso e reriloeng le sephetho se lakatsehang.

Polelo e Hatisitsoeng: Haeba ho se na litaelo tse ikhethang, lingoloa tsohle tse fumanehang sebakeng sena sa marang-rang ke tsa mantlha. Ka kopo bonts'a mohloli oa khatiso: https: //www.cncmachiningptj.com/ li -ththanks!

3, 4 le 5-axis e nepahetseng CNC lisebelisoa ditshebeletso tsa aluminium machiningberyllium, tšepe ea carbon, magnesium, mochini oa thaethaniamo, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite le lehong. E khona ho etsa likarolo tsa machining ho fihlela ho 98 in. turning dia. le +/-0.001 in. mamello e otlolohileng. Mehato e kenyelletsa ho sila, ho cheka, ho bora, ho ts'oara, ho tlanya, ho theha, ho loha, ho loants'a, ho qhekella, ho reaming le ho khaola laser. Litšebeletso tsa bobeli tse kang ho kopanya, ho sila ho se na setsi, ho phekola mocheso, ho pata le ho cheselletsa. Prototype le tlhahiso e tlase ho isa ho e phahameng e fanoang ka boholo ba li-unit tse 50,000. E loketse matla a mokelikeli, pneumatics, hydraulics le phunyang ditshebediso. E sebeletsa sebaka sa lifofane, lifofane, sesole, bongaka le ts'ireletso. sales@pintejin.com ) ka kotloloho bakeng sa projeke ea hau e ncha.

3, 4 le 5-axis e nepahetseng CNC lisebelisoa ditshebeletso tsa aluminium machiningberyllium, tšepe ea carbon, magnesium, mochini oa thaethaniamo, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite le lehong. E khona ho etsa likarolo tsa machining ho fihlela ho 98 in. turning dia. le +/-0.001 in. mamello e otlolohileng. Mehato e kenyelletsa ho sila, ho cheka, ho bora, ho ts'oara, ho tlanya, ho theha, ho loha, ho loants'a, ho qhekella, ho reaming le ho khaola laser. Litšebeletso tsa bobeli tse kang ho kopanya, ho sila ho se na setsi, ho phekola mocheso, ho pata le ho cheselletsa. Prototype le tlhahiso e tlase ho isa ho e phahameng e fanoang ka boholo ba li-unit tse 50,000. E loketse matla a mokelikeli, pneumatics, hydraulics le phunyang ditshebediso. E sebeletsa sebaka sa lifofane, lifofane, sesole, bongaka le ts'ireletso. sales@pintejin.com ) ka kotloloho bakeng sa projeke ea hau e ncha.

- 5 selekane Machining

- Cnc siloa

- Cnc fetola

- Mechini ea Machining

- Ts'ebetso ea Machining

- Phekolo ea bokaholimo

- Metal Machining

- Machining ea polasetiki

- Phofo Metallurgy hlobo

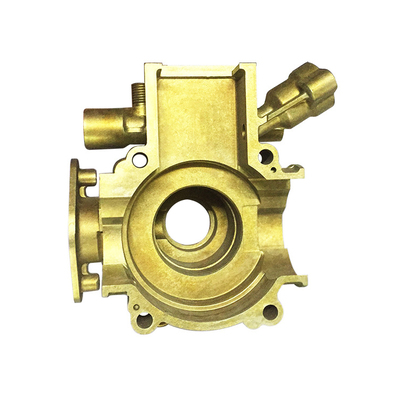

- Ho Casting

- Likarolo tsa Gallery

- Likarolo tsa Auto Metal

- Likarolo tsa mechine

- Sesebelisoa sa mocheso oa LED

- Likarolo tsa Kaho

- Likarolo tsa mobile

- Likarolo tsa Bongaka

- Likarolo tsa Elektroniki

- Machining e etselitsoeng

- Likarolo Tsa Baesekele

- Aluminium Machining

- Thaethaniamo Machining

- Lisebelisoa tsa Stainless Steel

- Koporo Machining

- Koporo Machining

- Super motsoako Machining

- Peek Machining

- Machining a UHMW

- Tlanya Machining

- Machining a PA6

- PPS Machining

- Mochini oa Teflon

- Inconel Machining

- Sesebelisoa sa Sesebelisoa sa Steel

- Boitsebiso bo Eketsehileng