Femtosecond Laser Cutting: Thepa ea Eona le Tšebeliso

Li-laser tsa Ultrafast li kenyelletsa lasers ea picosecond le ea femtosecond. Li-laser tsa Picosecond ke ntlafatso ea theknoloji ea li-nanosecond lasers, 'me li-picosecond lasers li sebelisa theknoloji ea ho notlela, ha li-nanosecond li sebelisa theknoloji ea Q-switched. Theknoloji ea Femtosecond e sebelisa tsela e fapaneng ka ho felletseng ea tekheniki. Leseli le hlahisoang ke mohloli oa peo le atolosoa ke pulse stretcher, le holisoa ke amplifier ea matla ea CPA, 'me qetellong le hatelloa ke pulse compressor ho ntša leseli. Theknoloji e thata ho feta.

Ha ho tluoa tabeng ea laser ea femtosecond, ntho ea pele e tlang kelellong e ka 'na ea e-ba litšebeliso tse tloaelehileng tse kang ho lokisoa ha femtosecond myopia le ho tlosoa ha femtosecond freckle e sebelisoang ho cosmetology ea bongaka. Li-laser tsa Femtosecond li boetse li arotsoe ka maqhubu a fapaneng a kang infrared, khanya e tala le ultraviolet. Har'a tsona, libaka tsa ts'ebeliso ea leseli la infrared li na le melemo e ikhethang: Li-lasers tsa infrared li ka monngoa ka mokhoa o ikhethileng ke lisebelisoa kapa limolek'hule mme ha li na libaka tse anngoeng ke mocheso ho Laser Cutting liindastering tse kang tsa elektroniki, photonics kapa bongaka. Hajoale, e ka sebelisoa libakeng tse ngata joalo ka ho nepahala ha thepa ho khaola laser, opereishene, bareki, puisano ea elektronike, spectroscopy, sefofane, lisebelisoa tsa ts'ireletso le saense ea motheo. Kahoo lekhetlong lena re tla hlahisa lisebelisoa tse 'maloa tse tloaelehileng tsa Be-Cu infrared femtosecond lasers indastering.

Khalase ea Laser Cutting Ultra-Thin Glass (UTG)

Hajoale, lisebelisoa tsa khalase tse tšesaane haholo li se li sebelisoa haholo lipontšong tsa elektronike tsa bareki le liindasteri tsa semiconductor. Mohlala, khalase ea substrate skrineng sa rona se sebelisoang hangata sa OLED ke khalase e tšesaane haholo (UTG).

Ka ntlafatso e tsoelang pele ea thekenoloji ea thekenoloji ea thelefono ea thelefono, li-skrini tsa thelefono tsa thelefono li ntse li fetoha tse nyenyane le tse sa tšoaneng, 'me theknoloji ea skrine ea ho phutha e hlahile kamoo linako li hlokang kateng. Leha ho le joalo, lifono tse phuthang skrineng li na le litlhoko tse phahameng haholo tsa khalase. Ha khalase e le mosesaane, ts'ebetso ea phetiso ea leseli e ntlafala, e khona ho tenyetseha hantle, 'me boima ba 'mele bo be bobebe. Leha ho le joalo, mofuta ona oa khalase ea elektronike Laser Cutting e hloka ho nepahala ho phahameng, ts'ebetso e phahameng, ha ho na li-micro-cracks, ha ho na mapheo a lefifi, joalo-joalo, ka lebaka leo, ho khaola ha laser ka matla ka khalase ea elektronike e fetohile mokhoa o ka sehloohong oa Laser Cutting hona joale, 'me joaloka rona. ditlhoko bakeng sa bohale chipping le micro-mapetsong eketseha, , femtosecond laser butle-butle fetohile molemo ka ho fetisisa khetho.

Femtosecond laser cutting e na le matla a phahameng haholo a matla 'me e ka feta habonolo moeli oa tšenyo ea khalase; ka nako e ts'oanang, khalase e tšesaane haholo e na le maikutlo a mocheso haholoanyane, 'me femtosecond pulse ke "mode e batang ea Laser Cutting", e ka etsang hore moeli oa sebaka sa leseli o phethehe, matheba a khanyang ha a kena-kenane,' me a finyelle. ultra-low fracture Effect: Nakong ea Laser Cutting process, lerako le lehlakoreng le ka etsoa le boreleli, ho phunyeha ho sa tloaelehang ha ho bonolo ho etsahala, 'me mapheo a sa tloaelehang a bakoang ke mocheso o feteletseng ha a khone ho etsahala. Ha e na tšusumetso ho radius e kobehang ea UTG mme e ka eketsa bophelo ba ho kobeha.

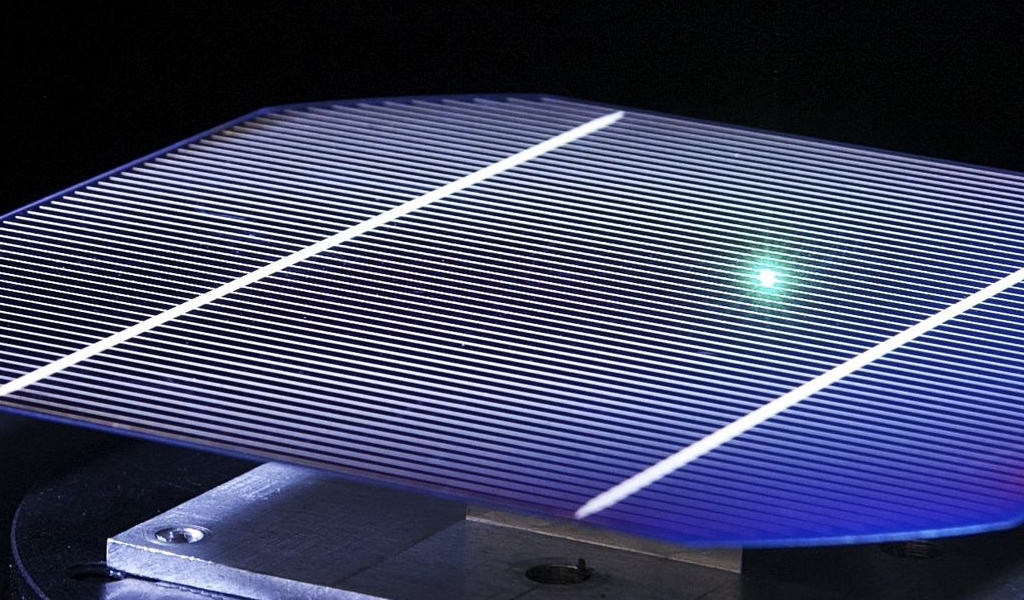

Laser Cutting Khauta-Plated Koporo Foil

Mehala ea koporo ke e 'ngoe ea likarolo tse sebelisoang haholo indastering ea lisebelisoa tsa elektroniki. Electrolyte ke electrolyte e mpe e kenngoa ka lera holim'a substrate ea boto ea potoloho 'me e sebetsa e le mokhanni oa motlakase oa boto ea potoloho. Foil ea koporo ke sehlahisoa se tšesaane haholo sa koporo. Koporo e tšoana le pampiri 'me botenya ba eona ke li-microns. Hangata 5um-135um, e mosesaane le e pharaletseng ho thata le ho feta ho e etsa. Ka mantsoe a bonolo feela, foil ea koporo e hatelloa ka maqephe a tšesaane haholo.

Foil ea koporo e sebelisoa haholo likarolong tsohle, joalo ka likoloi tsa motlakase, lisebelisoa tsa elektronike tsa bareki, sebaka sa sefofane, lisebelisoa tsa puisano le masimo a mang. Mokhoa oa setso oa Laser Cutting haholo-holo oa ho itšeha, empa ho na le mefokolo ea katleho, lebelo la Laser Cutting, tahlehelo le ho nepahala ha ho itšeha. Ha u sebelisa seha se tloaelehileng sa laser, phello ea mocheso e kholo. Phello ea mocheso mathōkong e etsa hore foil ea koporo e be bonolo ho sotha le ho senyeha, 'me metse e na le carbonized, e lebisang ho senyeha ha thepa.

Laser ea femtosecond e na le melemo e hlakileng haholoanyane ho Laser Cutting foil ea koporo ka lebaka la mokhoa oa eona o ikhethang oa "Laser Cutting". Laser ea Femtosecond e na le bophara bo fokolang ba pulse, e ka sebetsanang le thepa e nang le phello e fokolang haholo ea mocheso, ho qoba tšenyo ea thepa e bakoang ke ho bokella mocheso, le ho sireletsa hantle lesela le koahetsoeng ka khauta hore le se ke la oa;

Nakong ea ts'ebetso e tobileng ea ho itšeha, ho ke ke ha e-ba le ho fetoha ha mebala, ho se qhibilihe, ho se na tšilafalo ea lintho tse bonahalang, joalo-joalo; 'me laser ea femtosecond e na le tlhahiso e ntle ea boleng ba boleng. Ka mor'a ho tsepamisa maikutlo, e ka etsa bonnete ba ho lumellana ha phello ea bohale ba thepa e entsoeng le tsela ea ho itšeha. , ho batalla mahlakoreng ka bobeli a sefahleho sa ho qetela ho nolofalletsa ho itšeha ho nepahetseng; e boetse e ts'ehetsa mesebetsi e mengata ea ho hlophisa ho phatloha le ho otla ha pelo, ho ntlafatsa le ho ntlafatsa ts'ebetso ea Laser Cutting le phello.

Laser Cutting Zirconia Ceramics

Mabapi le li-ceramics, li-ceramic substrates tsa zirconia (YSZ) li na le mocheso o phahameng oa ho hanyetsa 'me li ka sebelisoa e le li-tubes tse futhumatsang, lisebelisoa tsa refractory le lisebelisoa tsa ho futhumatsa. 'Me e na le likarolo tse matla tsa ts'ebetso ea motlakase, boima bo phahameng, matla a phahameng a feto-fetohang le khanyetso e phahameng ea ho roala, thepa e ntle ea ho kenya mocheso oa mocheso, coefficient ea ho atolosa mocheso le melemo e meng e haufi le tšepe. E sebelisoa haholo-holo ka lithipa tsa ceramic, li-sensor tsa oksijene, lisebelisoa tsa mocheso bakeng sa lisele tsa mafura, lisele tsa mafura a Solid oxide le likarolo tse futhumatsang tsa mocheso o phahameng, jj.

Ha li bapisoa le litšepe, li-ceramics tsa zirconia li na le melemo ea ho hanyetsa ho apara hantle, bokaholimo bo boreleli, sebopeho se setle, 'me ha ho na oxidation. Mefuta e mengata e tsebahalang ea maemo a holimo e boetse e hlahisitse lioache tse phahameng tsa ceramic, tse nang le sebaka sa ho apara ka bohlale; li-ferrules tsa ceramic le matsoho li boetse li sebelisoa haholo tšimong ea fiber optical li-connectors; Ka nako e ts'oanang, li-ceramics tsa zirconia ha li na tšireletso ea matšoao, li khahlanong le ho theoha, ha li senyehe, 'me E na le melemo ea ho phutha, ponahalo e futhumetseng le e boreleli, le matsoho a matle, 'me e sebelisoa haholo masimong a elektroniki a 3C joalo ka mobile. mehala. Leha ho le joalo, nakong ea Laser Cutting ea li-ceramics tsa setso tsa zirconia, ho ke ke ha qojoa letoto la mathata a kang boleng bo bobe ba Laser Cutting le katleho e tlaase ea Laser Cutting. Sena se hloka tšebeliso ea femtosecond Laser Cutting, e ka rarollang bothata bona ka nepo le ka katleho.

Ka lebaka la tlhōrō e phahameng ea matla a femtosecond pulses, mokhoa o batang oa Laser Cutting o ka phethahala, o ka finyellang litlhoko tse tiileng tsa lihlahisoa. Nakong ea sehlahisoa sa Laser Cutting, laser ea femtosecond e sebelisa matla a fokolang 'me e baka tšenyo e fokolang ea thepa, kahoo ho nepahala ha Laser Cutting ho phahame; e seng ea setso Mechanical ho kopana Laser Cutting ha e na khatello ea maikutlo ebile e ajoa ka ho lekana pheletsong ea sampole. Ceramic chipping ha e na monyetla oa ho etsahala sebakeng se qhibilihisitsoeng mme boleng bo betere. Laser ea femtosecond e na le matla a matla haholo nakong ea ts'ebetso ea Laser Cutting mme e ka fihlela bokhoni bo sebetsang haholoanyane ba ho itšeha bakeng sa lisebelisoa tsa ceramic tsa zirconia. , e khonang ho potlakisa ho seha mehaho ea thepa ka sebōpeho.

Lisebelisoa tse ntseng li eketseha tsa liteko li paka melemo e meholo ea theknoloji ea femtosecond Laser Cutting (e nang le stent le hypotube laser ho itšeha) lebaleng la indasteri. Be-Cu e boetse e lula e e lema, e eketsa ts'ebetso ea liteko tsa kopo ho fana ka papali e felletseng ho melemo e mengata ea femtosecond le ho tsoela pele ho fana ka Phetoho le ntlafatso ea liindasteri tse tsoetseng pele tsa tlhahiso li rala motheo o tiileng le ho khothaletsa nts'etsopele.

3, 4 le 5-axis e nepahetseng CNC lisebelisoa ditshebeletso tsa aluminium machiningberyllium, tšepe ea carbon, magnesium, mochini oa thaethaniamo, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite le lehong. E khona ho etsa likarolo tsa machining ho fihlela ho 98 in. turning dia. le +/-0.001 in. mamello e otlolohileng. Mehato e kenyelletsa ho sila, ho cheka, ho bora, ho ts'oara, ho tlanya, ho theha, ho loha, ho loants'a, ho qhekella, ho reaming le ho khaola laser. Litšebeletso tsa bobeli tse kang ho kopanya, ho sila ho se na setsi, ho phekola mocheso, ho pata le ho cheselletsa. Prototype le tlhahiso e tlase ho isa ho e phahameng e fanoang ka boholo ba li-unit tse 50,000. E loketse matla a mokelikeli, pneumatics, hydraulics le phunyang ditshebediso. E sebeletsa sebaka sa lifofane, lifofane, sesole, bongaka le ts'ireletso. sales@pintejin.com ) ka kotloloho bakeng sa projeke ea hau e ncha.

3, 4 le 5-axis e nepahetseng CNC lisebelisoa ditshebeletso tsa aluminium machiningberyllium, tšepe ea carbon, magnesium, mochini oa thaethaniamo, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite le lehong. E khona ho etsa likarolo tsa machining ho fihlela ho 98 in. turning dia. le +/-0.001 in. mamello e otlolohileng. Mehato e kenyelletsa ho sila, ho cheka, ho bora, ho ts'oara, ho tlanya, ho theha, ho loha, ho loants'a, ho qhekella, ho reaming le ho khaola laser. Litšebeletso tsa bobeli tse kang ho kopanya, ho sila ho se na setsi, ho phekola mocheso, ho pata le ho cheselletsa. Prototype le tlhahiso e tlase ho isa ho e phahameng e fanoang ka boholo ba li-unit tse 50,000. E loketse matla a mokelikeli, pneumatics, hydraulics le phunyang ditshebediso. E sebeletsa sebaka sa lifofane, lifofane, sesole, bongaka le ts'ireletso. sales@pintejin.com ) ka kotloloho bakeng sa projeke ea hau e ncha.

- 5 selekane Machining

- Cnc siloa

- Cnc fetola

- Mechini ea Machining

- Ts'ebetso ea Machining

- Phekolo ea bokaholimo

- Metal Machining

- Machining ea polasetiki

- Phofo Metallurgy hlobo

- Ho Casting

- Likarolo tsa Gallery

- Likarolo tsa Auto Metal

- Likarolo tsa mechine

- Sesebelisoa sa mocheso oa LED

- Likarolo tsa Kaho

- Likarolo tsa mobile

- Likarolo tsa Bongaka

- Likarolo tsa Elektroniki

- Machining e etselitsoeng

- Likarolo Tsa Baesekele

- Aluminium Machining

- Thaethaniamo Machining

- Lisebelisoa tsa Stainless Steel

- Koporo Machining

- Koporo Machining

- Super motsoako Machining

- Peek Machining

- Machining a UHMW

- Tlanya Machining

- Machining a PA6

- PPS Machining

- Mochini oa Teflon

- Inconel Machining

- Sesebelisoa sa Sesebelisoa sa Steel

- Boitsebiso bo Eketsehileng