7A04 Alloy - Matla a Hlahisa Haufi le Matla a Tensile

7A04 alloy ke motsoako oa Al-Zn-Mg-Cu o khonang ho phekoleha mocheso oa aerospace super-hard aluminium alloy, e ka khonang ho phekoloa mocheso le ho matlafatsoa. Sebopeho sa eona se thathamisitsoe ho GB/T3190-2008, 'me e lumellana le motsoako oa B95 oa Soviet Union le Russia le AlZnMgCu1 ea Jeremane. .5.3.4365 motsoako oa lekana, hobane ka 1944 fektheri ea bo95 ea Soviet Union e ile ea atleha ho hlahisa sehlahisoa sena sa alloy semi-finished, kahoo e bitsoa B95 alloy. Ka 1957, China Northeast Light Alloy Co., Ltd. (eo ka nako eo e neng e le Harbin Aluminium Processing Plant) e ile ea hlahisa motsoako ona ka thuso ea litsebi tsa Soviet. Lipoleiti tsa alloy le lisebelisoa tse extruded.

Ntho e ka sehloohong ea motsoako oa 7A04 ke hore lihlahisoa tsa eona tsa Rpo.2 li haufi le matla a thata a Rm, polasetiki ea eona e tlaase, 'me e na le maikutlo a ho imeloa kelellong, haholo-holo ha e tlas'a meroalo ea ho sisinyeha le meroalo e tsitsitseng e pheta-phetoang. Bakeng sa moralo, tlhahiso le kopano ea likarolo, khatello ea maikutlo le lintlha tse eketsehileng tsa khatello ea maikutlo li lokela ho qojoa ka hohle kamoo ho ka khonehang. 7A04 alloy ha e hanyetsane le mocheso 'me e tla nolofatsa haholo haeba mocheso o sebetsang o phahame ho feta 125 ℃. Ho hanyetsa ha kutu ea khatello ea maikutlo ea li-workpieces tse teteaneng tsa 7A04 ka tsela e khuts'oane ea transverse (ST) e tlase.

Motsoako oa lik'hemik'hale oa 7A04 motsoako (boima%): 0.50Si, 0.50Fe, (1.4-2.0) Cu, (0.20-0.6) Mn, (1.8-2.8) Mg, (0.1-0.25) Cr, (5.0 --7.0) ) Zn, 0.10Ti, litšila tse ling ka bonngoe ke 0.05, kakaretso ke 0.10, ’me tse ling kaofela ke Al. Litlhaloso bakeng sa annealing e sa phethahalang ea 7A04 alloy semi-finished and intermediate product plates, strips, profiles, bar and pipes (290—320)℃/(2—4)h, moea o pholileng; lintlha tse khethehileng bakeng sa annealing ka ho feletseng (390—430) ℃/ (0.5-1.5) h, pholileng ea sebōpi ho ea ho ≤ 200 ℃ ka sekhahla sa phokotso ea mocheso oa ≤ 30 ℃/h, moea o pholileng o tsoa ka sebōping, kapa o halefa ka ho (320-380). ) ℃ bakeng sa (1-2) h. E le ho ntlafatsa ts'ebetso ea sebōpi sa metallurgical, fektheri e atisa ho chesa ho 400 ° C-420 ° C ka lihora tse 2, e e pholisa ho <150 ° C ka tekanyo ea 30 ° C / h, ebe e pholisa moea. sebopi.

Mocheso oa tharollo ea tharollo ea motsoako ona ke 465℃-475℃, o tingoa ka metsing ka mocheso oa kamore, 'me nako ea ho fetisa e khutšoanyane ho feta 25s. Hangata limela tse sebetsanang le aluminium li sebelisa phekolo e lebisitsoeng haholo ea tharollo le litlhaloso tsa phekolo ea botsofali ho latela lihlahisoa tse fapaneng le lihlahisoa tsa litlhaloso tse fapaneng.

Lisebelisoa tsa ho qhibilihisa le ho lahlela le mafura a motsoako oa 7A04 li tšoana le tsa lisebelisoa tse ling tsa aluminium. Leha ho le joalo, ka lebaka la mocheso oa eona o moholo oa mocheso o qhibilihisang le phapang e kholo ea sekhahla sa likarolo tse kholo tsa motsoako, karohano e atisa ho etsahala nakong ea ho qhibiliha, 'me ingot e atisa ho ba le mapetsong, ho lokoloha le tharollo. Ho bonolo ho fumana moea, 'me li-inclusions tse ngata tsa oxidized li tla thehoa ka hare ho ingot. E le ho fokotsa mefokolo ena, ntle le ho laola ka thata sebopeho sa motsoako, tlhokomelo e tlameha ho lefshoa ho laola mokhoa oa ho qhibiliha le oa ho lahla.

Thempereichara e pota-potileng ke 720℃—745℃, mocheso oa moea o kenang ke 725℃—740℃; mocheso oa letlapa ke 685℃—745℃; li-ingots tse kholoanyane, li-ingots tse sekoti le li-slabs li lokela ho behoa pele ho lahla , Karolo ea heke e lokela ho halefa ka mor'a ho lahla.

7A04 alloy e sebelisoa haholo ho etsa likarolo tsa sebopeho sa sefofane: maballo, likhoele, li-bulkheads, matlalo, likhopo, manonyeletso, ho lulisa. Lisebelisoa likarolo, joalo-joalo. Lihlahisoa tse seng li felile tse ka fanoang ke: lipoleiti, likhoele, profil, likhoele, litšepe, liphaephe, liphanele tsa lebota, mahala. betloa le ho shoa betloas, joalo-joalo.

Alloy e na le kutlo e phahameng ea notch le matla a tlase a axial tensile mokhathala. Sesebelisoa se tlameha ho khetha ka thata sebopeho sa sebopeho sa moralo, se khethe sebopeho se nang le khatello e tlase ea khatello ea maikutlo, 'me phetoho ea karolo ea karolo le likarolo tsohle tsa phetoho e lokela ho ba bonolo ho qoba bakeng sa liphetoho tsa tšohanyetso le phokotso ea eccentricity. ho ba ≥2mm. Qoba mengoapo, abrasions le bofokoli bo matla ha u lokisa likarolo.

Bakeng sa lihlahisoa tse kholo tse seng li felile, haholo liforomo tse kholo tse rarahaneng le li-profile, ts'ebetso e fapaneng e lokela ho hlahlojoa ka thata, 'me ho lokela ho etsoa liteko tse fapaneng tse sa senyeheng ho netefatsa hore liphoso li ka har'a sebaka se lumelletsoeng. Khanyetso ea kutu ea 7A04 alloy naheng ea T4 ha e tšoanelehe, kahoo botsofali ba maiketsetso boa hlokahala. Khanyetso ea kutu ea letlapa la alloy 7A04 ea khale ea maiketsetso e lekana le ea letlapa la alloy 2A12 le nang le aluminium e apereng. Khanyetso ea kutu ea lihlahisoa tse fetisitsoeng le likaroloana tse nyane tse fapaneng li lekana le tsa aluminium duralumin ea unclad. Phekolo ea botsofali e hlophisitsoeng ea 7A04 alloy e na le ts'ebetso e tšepahalang ea khatello ea maikutlo. Anodizing le kalafo ea ho penta holim'a metsi e ka sireletsa ka katleho thepa e ntšitsoeng. Corroded.

Letlapa la motsoako oa 7A04-T6 le na le modulus e ntle ea 66GN / mm2 ho 20 ° C, thepa e fetisitsoeng ea 71GN / mm2, le boima ba sefofane sa fracture Kc ea 50.64MN / (m3 / 2). Sebopeho sa semi-continuous casting 7A04 alloy ingot se kenyeletsa α-Al solid solution, T (AlCuMgZn) phase le S (Al2CuMg) phase, hammoho le mekhahlelo e nyenyane ea Mg2Si, AlFeMnSi le Al6 (FeMn). Sebopeho ka mor'a phekolo ea tharollo ke α S Ka mor'a ho tsofala ho 100 ℃-140 ℃, mohaho o fetoha α S MgZn2 T phase.

7A04 alloy e ka holofatsoa ke serame kapa mocheso. Sekhahla se chesang se senyang sa ingot se ka tlase kapa se lekana le 60%, 'me tekanyo e phahameng ea deformation ea thepa e holofetseng e ka fihla ho 80%. Mehaho e nang le libopeho tse rarahaneng e ka etsoa, 'me mocheso oa ho qapa ke 380°C-430°C. Ha ho etsoa khalemelo ea mocheso likarolong kapa lihlahisoa tse felileng, mocheso oa hlobo ke 130 ℃ ± 15 ℃, 'me mocheso oa karolo ka boeona ke 130 ℃ ± 10 ℃ kapa 150 ℃ ± 10 ℃. Nako ea ho tšoara 130℃±10℃ ke 10h—12h. Nako ea ho futhumatsa ho 150 ℃±10 ℃ ke 7h.

Boemo ba phepelo ea phanele ea lerako le pharalletseng ke T6, e ka lokisoa sebakeng sena, 'me e tlameha ho futhumatsoa sebakeng se secha se tingoeng. Mokhahlelo o le mong oa botsofali ke 140 ℃/16h; botsofali ba mekhahlelo e 'meli ho 120 ℃/3h 160 ℃/3h bo ka fumana ts'ebetso e ntle e felletseng. 7A04 alloy e na le ts'ebetso e ntle ea welding le machinability.

Kopanya le sengoloa sena: Motsoako oa 7A04 - Matla a Hlahisa Haufi le Matla a Tensile

Polelo e Hatisitsoeng: Haeba ho se na litaelo tse ikhethang, lingoloa tsohle tse fumanehang sebakeng sena sa marang-rang ke tsa mantlha. Ka kopo bonts'a mohloli oa khatiso: https: //www.cncmachiningptj.com/ li -ththanks!

3, 4 le 5-axis e nepahetseng CNC lisebelisoa ditshebeletso tsa aluminium machiningberyllium, tšepe ea carbon, magnesium, mochini oa thaethaniamo, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite le lehong. E khona ho etsa likarolo tsa machining ho fihlela ho 98 in. turning dia. le +/-0.001 in. mamello e otlolohileng. Mehato e kenyelletsa ho sila, ho cheka, ho bora, ho ts'oara, ho tlanya, ho theha, ho loha, ho loants'a, ho qhekella, ho reaming le ho khaola laser. Litšebeletso tsa bobeli tse kang ho kopanya, ho sila ho se na setsi, ho phekola mocheso, ho pata le ho cheselletsa. Prototype le tlhahiso e tlase ho isa ho e phahameng e fanoang ka boholo ba li-unit tse 50,000. E loketse matla a mokelikeli, pneumatics, hydraulics le phunyang ditshebediso. E sebeletsa sebaka sa lifofane, lifofane, sesole, bongaka le ts'ireletso. sales@pintejin.com ) ka kotloloho bakeng sa projeke ea hau e ncha.

3, 4 le 5-axis e nepahetseng CNC lisebelisoa ditshebeletso tsa aluminium machiningberyllium, tšepe ea carbon, magnesium, mochini oa thaethaniamo, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite le lehong. E khona ho etsa likarolo tsa machining ho fihlela ho 98 in. turning dia. le +/-0.001 in. mamello e otlolohileng. Mehato e kenyelletsa ho sila, ho cheka, ho bora, ho ts'oara, ho tlanya, ho theha, ho loha, ho loants'a, ho qhekella, ho reaming le ho khaola laser. Litšebeletso tsa bobeli tse kang ho kopanya, ho sila ho se na setsi, ho phekola mocheso, ho pata le ho cheselletsa. Prototype le tlhahiso e tlase ho isa ho e phahameng e fanoang ka boholo ba li-unit tse 50,000. E loketse matla a mokelikeli, pneumatics, hydraulics le phunyang ditshebediso. E sebeletsa sebaka sa lifofane, lifofane, sesole, bongaka le ts'ireletso. sales@pintejin.com ) ka kotloloho bakeng sa projeke ea hau e ncha.

- 5 selekane Machining

- Cnc siloa

- Cnc fetola

- Mechini ea Machining

- Ts'ebetso ea Machining

- Phekolo ea bokaholimo

- Metal Machining

- Machining ea polasetiki

- Phofo Metallurgy hlobo

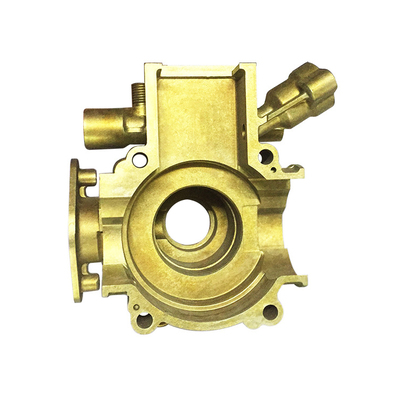

- Ho Casting

- Likarolo tsa Gallery

- Likarolo tsa Auto Metal

- Likarolo tsa mechine

- Sesebelisoa sa mocheso oa LED

- Likarolo tsa Kaho

- Likarolo tsa mobile

- Likarolo tsa Bongaka

- Likarolo tsa Elektroniki

- Machining e etselitsoeng

- Likarolo Tsa Baesekele

- Aluminium Machining

- Thaethaniamo Machining

- Lisebelisoa tsa Stainless Steel

- Koporo Machining

- Koporo Machining

- Super motsoako Machining

- Peek Machining

- Machining a UHMW

- Tlanya Machining

- Machining a PA6

- PPS Machining

- Mochini oa Teflon

- Inconel Machining

- Sesebelisoa sa Sesebelisoa sa Steel

- Boitsebiso bo Eketsehileng