Theknoloji ea phekolo ea mocheso ea aviation aluminium alloy

Ka nts'etsopele ea theknoloji ea lipalangoang, motsoako oa aluminium o 'nile oa sebelisoa haholo ho thepa ea lifofane ka lebaka la boima ba eona bo bobebe, matla a phahameng le ts'ebetso e bonolo. Tšebeliso e sebetsang ea alloy ea aluminium e fokotsa boima ba sebopeho sa sefofane, e ntlafatsa ts'ebetso ea sefofane le ho eketsa melemo ea moruo. Ka hona, theknoloji ea aviation aluminium alloy le eona e fumane tlhokomelo e eketsehileng.

Phekolo ea mocheso ea motsoako oa aluminium ka sebōpi sa moea sa potoloho ea moea sebakeng sa sebōpi sa nitrate

Tloaelo ea setso ea mocheso e sebelisa sebōpi sa nitrate bakeng sa ho futhumatsa, se nang le bofokoli ba tšilafalo e tebileng ea tikoloho, tšebeliso ea matla le litšila, ha sebōpi sa moea se tsamaisoang ke moea se na le melemo ea ho qala ka potlako le phello e ntle ea ho boloka matla, le nako ea phetisetso ea quenching. e potlakile ebile e khona ho feto-fetoha, e ka fihlelang litlhoko tsa likarolo tse fapaneng tsa motsoako oa aluminium. Hloka. Ka mor'a hore sebōpi sa motlakase se chesoe ke moea, ho tima tharollo ha ho silafatse sebaka sa ho pholisa, se leng molemo ho tsebahatsa tšebeliso ea li-organic quenching medium, ho fokotsa ho khopama ha phekolo ea mocheso, le ho ntlafatsa katleho ea tlhahiso.

Theknoloji ea bohlokoa ea sebōpi sa moea o potolohang moea ke mokhoa oa ho netefatsa ho ts'oana ha mocheso oa sebōpi (± 3 ± ± 5 ℃), haholo-holo bakeng sa libopi tse kholo, le mokhoa oa ho finyella litlhoko tsa mocheso o tlase (100 ~ 150 ℃) ho tšoana ha mocheso. Theknoloji ea bobeli ea bohlokoa ke mokhoa oa ho netefatsa nako ea phetisetso ea ho tima ka potlako, 'me e ka fetoloa le ho laoloa ho latela litlhoko tse fapaneng tsa likarolo.

Mokhoa oa ho tima lintho tse phelang

Aluminium alloy quenching medium e sebelisoa hangata ka metsi kapa metsi a chesang, empa bakeng sa pheko ea mocheso e kholo kapa deformation e thata, metsi a chesang a ke ke a finyella litlhoko, 'me ho lokela ho khethoa manyolo a quenching medium aqueous solution. Tšebeliso ea manyolo a quenching medium aqueous solution ho e-na le metsi moeeng oa sebōpi sa motlakase se fokotsa mocheso oa mocheso oa motsoako oa aluminium le nako ea ho lokisa. lesela la tšepe likarolo ka ho feta 50%.

Ho lemoha ha conductivity

Kaha lisebelisoa tsa alloy tsa aluminium li sebelisoa ha ho etsoa lifofane, liteko tsa tensile kapa liteko tsa boima li 'nile tsa sebelisoa ho bona boleng ba phekolo ea mocheso oa aluminium alloy. Ka mor'a hore motsoako oa aluminium o phekoloe mocheso, tlas'a matla a le mong (bothata), ho ka 'na ha e-ba le linaha tse peli tse fapaneng,' me ka tsela e fapaneng, tlas'a naha e le 'ngoe, ho ka' na ha e-ba le litekanyetso tse peli tse fapaneng tsa matla (bothata). Ka hona, ho sebelisa feela boima kapa matla ho laola boleng ba motsoako oa aluminium ka mor'a phekolo ea mocheso ke mokhoa oa khale oa ho lemoha 'me o ke ke oa netefatsa boleng ka ho feletseng.

Ho lemoha ha conductivity ho na le melemo e ikhethang ea boiketlo le ho potlaka, ts'ebetso e phahameng ea mosebetsi, 'me ha e le hantle ha e thibeloe ke sebōpeho le boima ba karolo e hlahlobiloeng,' me e na le molemo o ikhethang oa ho se be le tšenyo ea karolo. Ho tloha lilemong tsa bo-1980, tlhahlobo ea conductivity e 'nile ea sebelisoa butle-butle ho hlahloba boemo ba mocheso oa mocheso oa lisebelisoa / likarolo tsa aluminium alloy Chaena. Ka tekanyo ea GB/T12966-1991 "Aluminium Alloy Electrical Conductivity Eddy Current Test Method", mokhoa oa teko o fanoa, GJB2894-l997 "Aluminium Alloy Electrical Conductivity and Hardness Dequirements", e hlakisang motlakase oa motlakase le litlhoko tsa boleng ba boima.

Kopanya le sengoloa sena: Theknoloji ea phekolo ea mocheso ea aviation aluminium alloy

Phatlalatso ea Khatiso: Haeba ho se na litaelo tse khethehileng, lingoliloeng tsohle tse sebakeng sena ke tsa mantlha. Ka kopo, bontša mohloli oa khatiso hape: https://www.cncmachiningptj.com

PTJ® ke moetsi ea ikhethileng ea fanang ka mefuta e fapaneng ea mekoallo ea koporo, likarolo tsa koporo 'me likarolo tsa koporo. Mekhoa e tloaelehileng ea tlhahiso e kenyelletsa ho koala, ho khabisa, ho etsa koporo, terata edm litšebeletso, ho hlohlona, ho bopa le ho kobeha, ho halefisa, ho chesa betloa le ho hatella, ho phunyeletsa le ho otla, ho roala khoele le ho kokota, ho kuta, machining a mangata a spindle, extrusion le tšepe e betlang 'me stamp. Likopo li kenyelletsa mekoallo ea libese, li-conductors tsa motlakase, likhoele tsa coaxial, waveguides, likaroloana tsa transistor, li-tubes tsa microwave, li-tubes tsa hlobo tse se nang letho, le metallurgy ea phofo litanka tsa extrusion.

PTJ® ke moetsi ea ikhethileng ea fanang ka mefuta e fapaneng ea mekoallo ea koporo, likarolo tsa koporo 'me likarolo tsa koporo. Mekhoa e tloaelehileng ea tlhahiso e kenyelletsa ho koala, ho khabisa, ho etsa koporo, terata edm litšebeletso, ho hlohlona, ho bopa le ho kobeha, ho halefisa, ho chesa betloa le ho hatella, ho phunyeletsa le ho otla, ho roala khoele le ho kokota, ho kuta, machining a mangata a spindle, extrusion le tšepe e betlang 'me stamp. Likopo li kenyelletsa mekoallo ea libese, li-conductors tsa motlakase, likhoele tsa coaxial, waveguides, likaroloana tsa transistor, li-tubes tsa microwave, li-tubes tsa hlobo tse se nang letho, le metallurgy ea phofo litanka tsa extrusion.

Re bolelle hanyane ka tekanyetso ea projeke ea hau le nako e lebelletsoeng ea ho fihla. Re tla rera leano la ho fana ka lits'ebeletso tse baballang litšenyehelo ho u thusa ho fihlela sepheo sa hau, O amohelehile ho ikopanya le rona ka kotloloho ( sales@pintejin.com ).

- 5 selekane Machining

- Cnc siloa

- Cnc fetola

- Mechini ea Machining

- Ts'ebetso ea Machining

- Phekolo ea bokaholimo

- Metal Machining

- Machining ea polasetiki

- Phofo Metallurgy hlobo

- Ho Casting

- Likarolo tsa Gallery

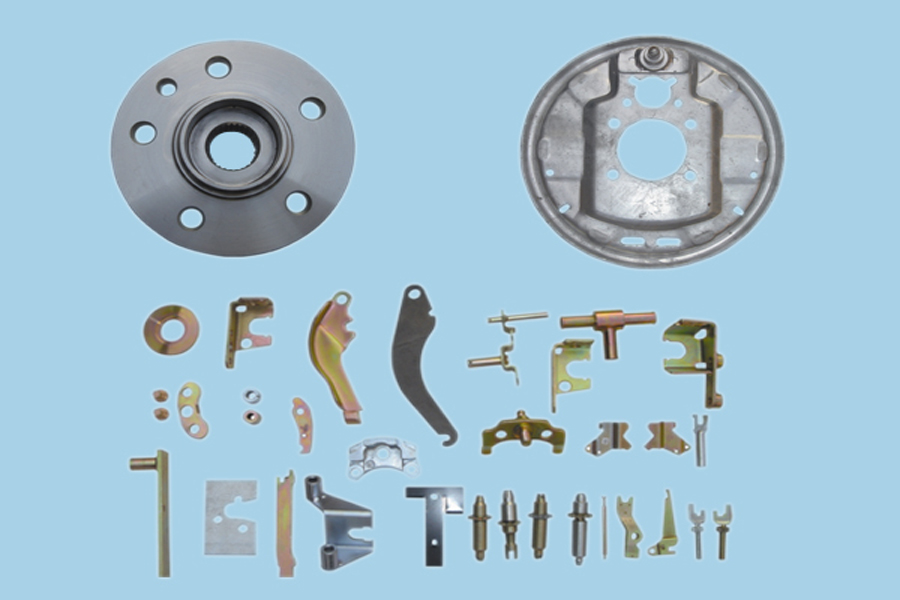

- Likarolo tsa Auto Metal

- Likarolo tsa mechine

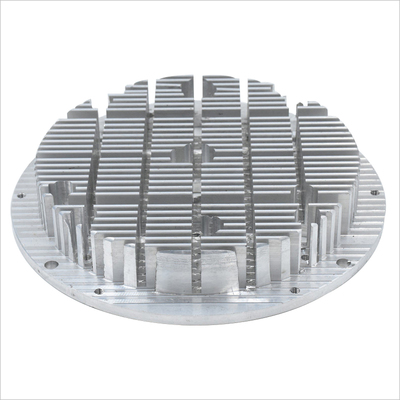

- Sesebelisoa sa mocheso oa LED

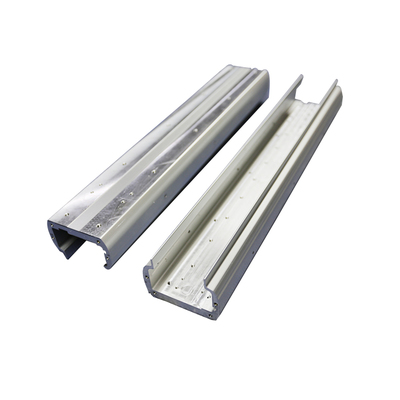

- Likarolo tsa Kaho

- Likarolo tsa mobile

- Likarolo tsa Bongaka

- Likarolo tsa Elektroniki

- Machining e etselitsoeng

- Likarolo Tsa Baesekele

- Aluminium Machining

- Thaethaniamo Machining

- Lisebelisoa tsa Stainless Steel

- Koporo Machining

- Koporo Machining

- Super motsoako Machining

- Peek Machining

- Machining a UHMW

- Tlanya Machining

- Machining a PA6

- PPS Machining

- Mochini oa Teflon

- Inconel Machining

- Sesebelisoa sa Sesebelisoa sa Steel

- Boitsebiso bo Eketsehileng