Tlhokahalo ea boemo le nts'etsopele ea lisebelisoa tsa welding

Selelekela: China ke naha e nang le tšebeliso e kholo ka ho fetisisa ea lisebelisoa tsa tšepe le litšepe lefatšeng. Ho ea ka lipalo-palo tse amehang ka 2016, tlhahiso ea tšepe ea China ke lithane tse limilione tse likete tse 1.138, tse etsang karolo e fetang halofo ea lihlahisoa tsa tšepe tsa lefats'e, 'me tlhahiso ea thepa ea ho tjheseletsa e ka bang lithane tse limilione tse 5.68, e leng hoo e ka bang halofo ea lihlahisoa tsa lefats'e tsa tjheseletsa. .

1. Tlhokahalo ea 'maraka ea lisebelisoa tsa welding le boemo ba hona joale ba tlhoko ho latela indasteri

1. Tlhokahalo ea 'maraka e tla tsoela pele ho eketseha

Tlaleho ea Khonkerese ea Naha ea bo-18 ea Mokha oa Makomonisi oa naha ea heso e bontšitse ka ho hlaka hore o mong oa mesebetsi ea mantlha ea kaho ea moruo oa China lekholong la mashome a mabeli a motso o mong ke ho phethahatsa kholo ea indasteri. Naha ya rona e se e le kgatong ya ntshetsopele ya nako ya mahareng ya boindaseteri. Nalane ea linaha tse fapaneng lefats'eng e bonts'a hore ha naha e le nakong ea kholo ea indasteri, ts'ebeliso ea lisebelisoa tsa tšepe le litšepe li tla tsoela pele ho hola. Ka mohlala, ha United States le Japane ha e le hantle li qeta khoebo ea tsona ea indasteri ka bo-1970, tšebeliso ea tšepe le thepa ea ho cheseletsa e ile ea fihla sehlohlolong ’me ea fokotseha butle-butle.

Lilemong tse 10 tse tlang, tšebeliso ea lisebelisoa tsa tšepe le litšepe naheng ea heso e tla tsoela pele ho hola, empa sekhahla sa kholo se tla fokotseha ka mokhoa o itekanetseng, 'me ho tla tsepamisoa maikutlo holim'a tokiso ea mefuta-futa ea lihlahisoa le ntlafatso ea boleng. Ho latela se boletsoeng esale pele ke litsebi tse amehang, tšebeliso ea tšepe ea naha ea heso e ka fihla ho lithane tse limilione tse likete tse 1.2 ho isa ho tse 1.5 ka lilemo tse 10. Ka hona, tlhokahalo e lumellanang ea lisebelisoa tsa welding e ka fihla ho lithane tse limilione tse 7-8.

2. Ho ea ka litlhoko tsa indasteri

Ho ea ka tlhokahalo ea indasteri, phapang e kholo ka ho fetisisa pakeng tsa lisebelisoa tsa tšepe le litšepe tsa naha ea heso le linaha tse tsoetseng pele tse tsoetseng pele ke: lilemong tsa morao tjena, tšepe ea kaho ea naha ea heso e ka bang 55%, 'me tlhahiso ea indasteri e sebelisa tlase ho 45%. Leha ho le joalo, tšepe ea hona joale ea kaho United States, Europe le Japane E ikarabella feela bakeng sa 22% ~ 30%, le tšepe bakeng sa litlaleho tsa tlhahiso ea indasteri bakeng sa 60% ~ 66%. Phapang ena e boetse e bonahatsa litšobotsi tsa mohato oa hona joale oa tsoelo-pele naheng ea heso, moo palo e kholo ea mehaho ea mehaho le mehaho ea litoropo e ntseng e etsoa.

2. Mokhoa o ka sehloohong oa nts'etsopele ea lisebelisoa tsa welding

1. Tsoelo-pele ea li-welding automation e khothalletsa ho lokisoa ha sebopeho sa lisebelisoa tsa welding

Bohareng ba lilemo tsa bo-1980, karolo ea lithupa tsa ho cheselletsa linaheng tse tsoetseng pele ho ea ho lisebelisoa tsa ho cheselletsa e ne e ka ba 50%. Ka 2004, Europe, Amerika Leboea (United States le Canada) le Japane, karolo ea lithupa tsa ho tjheseletsa ha ho sebelisoa thepa ea ho tjheseletsa e ne e le ka tlase ho 20%. Ka mantsoe a mang, ts'ebeliso ea hona joale ea li-welding le li-semi-automated welding linaheng tse tsoetseng pele ke eona e ikarabellang bakeng sa mosebetsi oohle oa ho cheselletsa. Ho feta 80%.

2. Tsoelo-pele ea theknoloji ea tšepe e khothalletsa ho nchafatsa le ho ntlafatsa boleng ba lisebelisoa tsa ho cheselletsa

naha ea heso e hahamalla ho ntlafala ho tloha naheng e kholo ea tšepe ho ea ho naha e matla ea tšepe. Lilemong tsa morao tjena, ho hlahisitsoe litšepe tse ngata tse ntlafalitsoeng, tse sebetsang hantle le tsa boleng bo holimo. Haholo-holo, thepa ea tlhahiso le boemo ba theknoloji ea indasteri ea tšepe e entse tsoelo-pele e kholo, e kang tse leshome tse tla kenngoa tlhahisong ka mor'a e 'ngoe. Ts'ebetso ea liloala tse ngata tse mahareng le tse boima tse roalang lipoleiti li tla feta tsa tse ntseng li le teng Japane le United States 'me e be moloko o mocha oa liloala tsa sejoale-joale tse bilikang lipoleiti tse boima lefatšeng. Sena se tla rala motheo o tiileng bakeng sa phethahatso ea mekhoa ea ho pholisa e laoloang le e laoloang le tlhahiso ea lipoleiti tse phahameng, tse sebetsang hantle le tse boima. Thepa motheo.

3. Bakeng sa lisebelisoa tse tloaelehileng tsa welding tse nang le bongata bo boholo le mefuta e mengata e fapaneng, mokhoa oa 'maraka oa boleng bo phahameng le theko e ntle o lokela ho khothaletsoa.

The atileng ka ho fetisisa tjheseletsa consumables hlahisoa le chesoa naheng ea heso hona joale, ho akarelletsa le k'habone tšepe tjheseletsa melamu tse kang mateano 422, HJ431 flux, ER50-6 koporo-plated tjheseletsa terata le lihlahisoa tse ling, ka lebaka la katoloso ya bokgoni ba tlhahiso le oversupply, the Litheko tsa lapeng le tsa kantle ho naha tsa thepa e tloaelehileng ea tjheseletsa naheng ea heso li ntse li theko e boima le ho feta. Li lekana feela le 50% ho isa ho 60% ea theko ea lisebelisoa tse ts'oanang tsa boleng bo holimo 'marakeng oa machaba. Lik'hamphani tse ling tse sebelisang li-welding li amohetse mekhoa e khopo ea tlholisano ea "litheko tse tlase, boleng bo tlase le theko e tlase". Ka hona, lilemong tsa morao tjena, basebelisi ba bangata ba malapeng ba tlalehile ba bang Boleng ba lisebelisoa tse tloaelehileng tsa welding tse kang 422 rod welding ha boa ka ba ntlafala, empa bo fokotsehile.

Mebaraka ea kantle e bonts'a hore lisebelisoa tse tloaelehileng tsa ho cheselletsa tse romelloang kantle ho naha ke likhoebo tse ling tsa China ke "litheko tse tsoang kantle ho naha tsa boleng bo tlase". Le hoja theko e le theko e tlaase, boleng ha bo botle. E ka sebelisoa feela mererong ea bobeli, e nang le tšusumetso e mpe setšoantšong sa naha ea heso ea "welding consumables."

4. Khothaletsa tšebelisano-'moho le litsi tsa tšepe ho rarolla bothata ba khaello ea mefuta ea terata ea welding

Tšitiso e kholo nts'etsopele ea lisebelisoa tsa ho cheselletsa litšepe naheng ea heso ke hore mefuta e fapaneng le boleng ba terata e tiileng e sirelelitsoeng ka khase le terata e tiileng ea arc e kentsoeng ka metsing ha e khone ho fihlela tlhoko ea 'maraka. Ho kenyeletsoa maemo a fapaneng a matla a terata ea tšepe e matla haholo, terata ea tšepe e sa cheseheng mocheso, terata ea tšepe e sa cheseheng mocheso o tlase, terata ea tšepe e sa kutung moeeng, terata ea tšepe e sa cheseheng, jj.

Ha e le seo ho thoeng ke terata e se nang koporo ea welding e hlahisoang ke bahlahisi ba malapeng le ba tsoang linaheng tse ling, e lokela ho bitsoa terata e khethehileng e koahetsoeng. Ka lebaka la sebopeho se fapaneng sa ho roala le kalafo holim mekhoa ea moetsi e mong le e mong, ts'ebetso ea terata ea welding e boetse e fapane. Thepa e phahameng ea ts'ebetso le kalafo holim ts'ebetso ha e bapalle feela karolo ea thibelo ea mafome le lubrication, ha ho na mosi oa koporo o hlahisoang nakong ea welding, empa hape o ka ntlafatsa botsitso ba arc ea terata ea welding le ho fokotsa spatter ea welding. Hona joale, bahlahisi ba malapeng le ba tsoang linaheng tse ling ba ntse ba ntlafatsa ho roala le kalafo holim mokhoa oa ho tjheseletsa terata ena. Ho lebelletsoe hore motsoako oa mofuta ona oa terata le mochini oa welding oa dijithale o laolang phetoho ea arc ka nepo o ka fihlela ts'ebetso e phahameng, e tlase-spatter e phahameng ea hona joale CO2 welding, mme e fihlelle ts'ebetso e lekanang le terata e nang le flux-cored. welding, e leng tataiso ea tsoelo-pele ea nakong e tlang.

Kopanya le sengoloa sena: Tlhokahalo ea boemo le nts'etsopele ea lisebelisoa tsa welding

Phatlalatso ea Khatiso: Haeba ho se na litaelo tse khethehileng, lingoliloeng tsohle tse sebakeng sena ke tsa mantlha. Ka kopo, bontša mohloli oa khatiso hape: https://www.cncmachiningptj.com

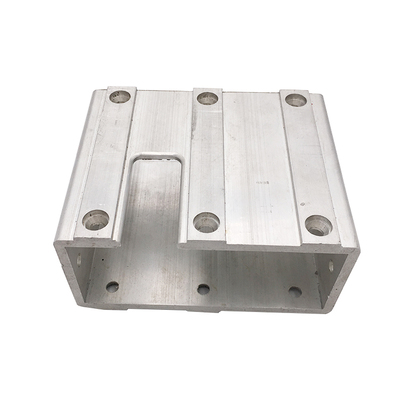

PTJ® ke moetsi ea ikhethileng ea fanang ka mefuta e fapaneng ea mekoallo ea koporo, likarolo tsa koporo 'me likarolo tsa koporo. Mekhoa e tloaelehileng ea tlhahiso e kenyelletsa ho koala, ho khabisa, ho etsa koporo, terata edm litšebeletso, ho hlohlona, ho bopa le ho kobeha, ho halefisa, ho chesa betloa le ho hatella, ho phunyeletsa le ho otla, ho roala khoele le ho kokota, ho kuta, machining a mangata a spindle, extrusion le tšepe e betlang 'me stamp. Likopo li kenyelletsa mekoallo ea libese, li-conductors tsa motlakase, likhoele tsa coaxial, waveguides, likaroloana tsa transistor, li-tubes tsa microwave, li-tubes tsa hlobo tse se nang letho, le metallurgy ea phofo litanka tsa extrusion.

PTJ® ke moetsi ea ikhethileng ea fanang ka mefuta e fapaneng ea mekoallo ea koporo, likarolo tsa koporo 'me likarolo tsa koporo. Mekhoa e tloaelehileng ea tlhahiso e kenyelletsa ho koala, ho khabisa, ho etsa koporo, terata edm litšebeletso, ho hlohlona, ho bopa le ho kobeha, ho halefisa, ho chesa betloa le ho hatella, ho phunyeletsa le ho otla, ho roala khoele le ho kokota, ho kuta, machining a mangata a spindle, extrusion le tšepe e betlang 'me stamp. Likopo li kenyelletsa mekoallo ea libese, li-conductors tsa motlakase, likhoele tsa coaxial, waveguides, likaroloana tsa transistor, li-tubes tsa microwave, li-tubes tsa hlobo tse se nang letho, le metallurgy ea phofo litanka tsa extrusion.

Re bolelle hanyane ka tekanyetso ea projeke ea hau le nako e lebelletsoeng ea ho fihla. Re tla rera leano la ho fana ka lits'ebeletso tse baballang litšenyehelo ho u thusa ho fihlela sepheo sa hau, O amohelehile ho ikopanya le rona ka kotloloho ( sales@pintejin.com ).

- 5 selekane Machining

- Cnc siloa

- Cnc fetola

- Mechini ea Machining

- Ts'ebetso ea Machining

- Phekolo ea bokaholimo

- Metal Machining

- Machining ea polasetiki

- Phofo Metallurgy hlobo

- Ho Casting

- Likarolo tsa Gallery

- Likarolo tsa Auto Metal

- Likarolo tsa mechine

- Sesebelisoa sa mocheso oa LED

- Likarolo tsa Kaho

- Likarolo tsa mobile

- Likarolo tsa Bongaka

- Likarolo tsa Elektroniki

- Machining e etselitsoeng

- Likarolo Tsa Baesekele

- Aluminium Machining

- Thaethaniamo Machining

- Lisebelisoa tsa Stainless Steel

- Koporo Machining

- Koporo Machining

- Super motsoako Machining

- Peek Machining

- Machining a UHMW

- Tlanya Machining

- Machining a PA6

- PPS Machining

- Mochini oa Teflon

- Inconel Machining

- Sesebelisoa sa Sesebelisoa sa Steel

- Boitsebiso bo Eketsehileng