Boemo ba maemo le mathata a teng a indasteri ea ho cheselletsa

Tlhahiso ea lisebelisoa tsa ho cheselletsa litšepe naheng ea heso e eketsehile ka kakaretso ho latela tšepe, 'me tlhahiso e ntse e eketseha lilemong tsa morao tjena. Feela bala li-electrode le lithapo, khumo ea e ne e le lithane tse ka 629,600 ka 1996, boima ba lithane tse limilione tse 1.449 ka 2002, 'me boima ba lithane tse limilione tse 1.7 ka 2003 (ho akarelletsa le boima ba lithane tse limilione tse 1.2 tsa li-electrode, lithane tse 300,000 tsa lithapo tiileng, lithane tse 35,000 tsa lithapo ts'ebetsong-cored, koahetsoe selikalikoe Welding wire flux lithane tse 200,000), ke naha e kholo ka ho fetisisa lefatšeng ea tlhahiso ea thepa le tšebeliso ea thepa.

Leha ho le joalo, tlhahiso ea li-electrode tsa tjheseletsa tsa li-electrode ka lisebelisoa tsa ho tjheseletsa tse hlahisoang naheng ea heso li 'nile tsa ikarabella bakeng sa hoo e ka bang 75%,' me kakaretso ea lithapo tse sa tšoaneng tsa tjheseletsa e ka bang 25%. Baloa motheong oa tšepe depositi, ka 2002, tjheseletsa mechine le sekgahla se ikemetseng naheng ea heso se ne se ka fihla ho 40.1% feela, ha linaha tse tsoetseng pele liindasteri lefatšeng ka bophara li ka holimo ho 60% -70%. Ho ka bonoa hore sekhahla sa automation sa tlhahiso ea welding naheng ea heso se ntse se le tlase ka kakaretso. Phapang e teng lipakeng tsa indasteri ea lintho tse sebelisoang naheng ea heso le linaha tse tsoetseng pele ha e sa le joalo ka tlhahiso, empa ho latela boleng ba kakaretso le boemo ba lipatlisiso tsa saense, ho kenyeletsoa boleng ba basebetsi, boemo ba taolo, thepa ea tlhahiso, theknoloji ea liteko, nts'etsopele ea lihlahisoa joalo-joalo.

1. Molamu oa welding

Hona joale, ho na le baetsi ba li-electrode tse ka bang 500 naheng ea heso, bao ba ka bang 300 ba nang le maemo a phethahetseng a tlhahiso, mekhoa ea ho hlahloba le mokhoa o utloahalang oa ho netefatsa boleng, 'me hoo e ka bang 200 ba na le maemo a itseng a tlhahiso empa ba haelloa ke mekhoa ea ho hlahloba. Bokhoni ba tlhahiso ea indasteri bo ka ba lithane tse limilione tse 150. Ka 2003, tlhahiso ea molamu oa welding e ne e le lithane tse limilione tse 1.2.

Baetsi ba li-electrode tsa welding ba fumaneha libakeng tsohle ntle le Tibet, 'me mefuta ea bona ea moruo e kenyelletsa tsa mmuso, tse kopaneng, tsa poraefete, tse kopanetsoeng, khoebo e le 'ngoe le ho ba le kabelo. Lithupa tsa welding li hlahisoa ho baetsi ba lisebelisoa tse ngata tse kholo tsa welding, joalo ka Tianjin Jinqiao Welding Materials Company, Tianjin Bridge Group Company, Sichuan Atlantic Group Company, joalo-joalo. Mefuta ena haholo-holo ke li-electrode tsa tšepe tsa sebopeho, hammoho le li-electrode tsa tšepe tse sa keneleng mocheso, tšepe e sa hloekang. li-electrode, li-electrode tse holim'a holim'a metsi, li-electrode tse thehiloeng ho nickel, li-electrode tsa tšepe tse entsoeng ka tšepe le li-electrode tse ling tsa morero o khethehileng.

2. Wilding terata

2.1, terata ea welding e sirelelitsoeng ka khase

Hajoale, ho na le baetsi ba terata ba sirelelitsoeng ka khase ba 200-250 naheng ka bophara, 'me lisebelisoa tse ka bang 50 tsa lisebelisoa tse fapaneng tsa tlhahiso li rekisitsoe ho tsoa Jeremane, Sweden, Canada, Japan, Switzerland, Italy le Taiwan, le tse fetang 100 tsa malapeng. kapa lisebelisoa tse iketselitseng tsona. Matla a tlhahiso ea selemo le selemo a haufi le lithane tse 600-700,000. Ka 2003, tlhahiso ea terata e tiileng ea welding e ne e le lithane tse 300,000.

Likhoebo tsa tlhahiso ea likhoele tse tiileng tsa mantlha li entsoe haholo ka tsa mmuso, tse kopaneng, tsa poraefete, tsa kopanelo le tsa khoebo e le 'ngoe. Limela tse ling tse kholo tsa tlhahiso ea li-electrode li se li fetohile mokokotlo oa tlhahiso ea terata ea welding. Limela tse kholoanyane tsa tlhahiso li kenyelletsa Jinzhou Jintai Metal Industry Co., Ltd., Sichuan Atlantic Welding Wire Products Co., Ltd., joalo-joalo, ho na le mefuta e fokolang ea terata e sirelelitsoeng ka khase. Ntle le mefuta ea ER49-1 le ER50-6, e nang le palo e kholo ea tlhahiso, boholo ba mefuta e meng e na le tlhahiso e nyane.

2.2. terata e sirelelitsoeng ka khase e sirelelitsoeng ka likhoele tsa ho cheseha

terata e tsoetseng pele ea tjheseletsa ea flux-cored, ka lebaka la ts'ebetso ea eona e ikhethang ea ts'ebetso, e fetohile tjheseletsa e ntseng e hola ka potlako naheng ea heso, ho tloha ho lithane tse ka tlase ho 1,000 (haholo-holo terata e teteaneng) ka 1996 ho isa ho lithane tse 35,000 (haholo-holo terata e tšesaane) ka 2003, sekhahla sa kholo ea selemo le selemo se fetang 50%. Nakong e fetileng, haholo-holo e ne e itšetlehile ka thepa e tsoang linaheng tse ling. Hona joale ho feta 50% ea terata e nang le flux-cored welding e sebelisoang Chaena e hlahisoa ka boeona, 'me ho na le palo e nyenyane ea ho romela kantle ho naha. Libaka tsa kopo li atolohile butle-butle ho tloha mohahong oa likepe ho ea mohahong, marokho, mechine e boima, li-boilers, likepe tsa khatello, liphaephe, mehaho ea tšepe le liindasteri tse ling.

Ho na le bahlahisi ba 29 ba terata e nang le flux-cored welding naheng ka bophara le mela ea tlhahiso e 49, ho kenyeletsoa mela e 25 ea tlhahiso e tsoang kantle ho naha (ho kenyeletsoa e 3 e entsoeng Taiwan) le e 24 e hlahisoang lapeng, e nang le tlhahiso ea selemo le selemo ea lithane tse fetang 50,000. Ho na le limela tse 4 tse kholo tsa tlhahiso ea terata ea flux-cored China, e leng Tiantai Welding Materials (Kunshan) Co., Ltd., Guangtai Welding Materials Co., Ltd., Tianjin Sanying Welding Industry Co., Ltd., le Antai Technology Co., Ltd. Welding Materials Division Company (Beijing Ganglian Welding Materials Co., Ltd. e kopane le khamphani ena ka 2003).

Hajoale, lihlahisoa tsa naha ea heso tse nang le likhoele tse chesehang li kenyelletsa letoto le le leng la ts'ireletso ea khase ea titanium, ts'ireletso ea khase ea alkaline le holim'a holim'a metsi. Li loketse bakeng sa tšepe ea carbon, tšepe e tlaase-alloy e matla, tšepe e sa hloekang, joalo-joalo, 'me e ka finyella litlhoko tsa tjheseletsa tsa mehaho ea boenjiniere ka kakaretso.

2.3. terata ea welding ea arc e kentsoeng ka metsing le flux

Sehlahisoa sa terata ea welding ea arc e ka tlas'a metsi le eona e eketsehile haholo lilemong tsa morao tjena, empa e etsa feela karolo ea 5.5% ea kakaretso ea lisebelisoa tsa welding. Karolo ea terata ea ho tjheseletsa ea arc e ka tlas'a metsi linaheng tse tsoetseng pele indastering hangata e lipakeng tsa 8-10%.

Kaha tlhahiso ea terata e kentsoeng ka metsing ea arc e batla e le bonolo, lifeme tse akaretsang tsa li-electrode le lifeme tsa terata ea tšepe li ka fana ka eona. Ho na le lik'hamphani tse makholo tse ka fanang ka terata e ka tlas'a metsi ea arc, 'me lik'hamphani tse ling li fana ka eona ka mokhoa oa disk. Ka 2003, tlhahiso e ne e ka ba lithane tse 80,000.

Haholo-holo ho na le mefuta e 'meli ea li-arc fluxes tse ka tlas'a metsi, mofuta oa ho qhibilihisa le mofuta oa sintered. Haholo-holo naha ea rona e hlahisa le ho sebelisa smelted flux. Hajoale, ho na le lik'hamphani tse fetang 30 tse hlahisang lithane tse ka bang 150,000 selemo le selemo, tseo smelted flux e leng lithane tse 110,200,000, 'me sintered flux ke lithane tse 30,000 ho isa ho tse 40,000. Ho na le lik'hamphani tse fetang 10 tse khonang ho hlahisa sintered flux. Lilemong tsa morao tjena, 'maraka oa sintered flux Ka katoloso e tsoelang pele, karolo ea sintered flux e ntse e eketseha. Ka 2003, tlhahiso ea metsi a arc flux e ne e ka ba lithane tse 120,000.

3. Ho na le mathata

⑴ Theko ea 'maraka ea lapeng ea lisebelisoa tsa ho cheselletsa e tlase haholo, haholo theko ea li-welding rod e tlase haholo, e bakang ntho e mpe;

⑵ Ho na le lihlahisoa tse 'maloa tse ikhethileng, joalo ka lithupa tse tjheseletsang mosi o tlase tse sebelisetsoang ho tiisa libaka, lithupa tsa welding tse nang le matla a matla a anti-porosity a koahetsoeng ka lesela le thibelang mafome, joalo-joalo;

(3) Mefuta e fapa-fapaneng ea terata e tiileng-core welding e nyenyane, e fokolang haholo-holo ka phepelo ea tšepe.

Kopanya le sengoloa sena: Boemo ba maemo le mathata a teng a indasteri ea ho cheselletsa

Phatlalatso ea Khatiso: Haeba ho se na litaelo tse khethehileng, lingoliloeng tsohle tse sebakeng sena ke tsa mantlha. Ka kopo, bontša mohloli oa khatiso hape: https://www.cncmachiningptj.com

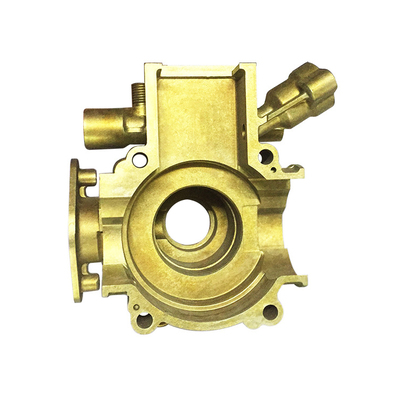

PTJ® ke moetsi ea ikhethileng ea fanang ka mefuta e fapaneng ea mekoallo ea koporo, likarolo tsa koporo 'me likarolo tsa koporo. Mekhoa e tloaelehileng ea tlhahiso e kenyelletsa ho koala, ho khabisa, ho etsa koporo, terata edm litšebeletso, ho hlohlona, ho bopa le ho kobeha, ho halefisa, ho chesa betloa le ho hatella, ho phunyeletsa le ho otla, ho roala khoele le ho kokota, ho kuta, machining a mangata a spindle, extrusion le tšepe e betlang 'me stamp. Likopo li kenyelletsa mekoallo ea libese, li-conductors tsa motlakase, likhoele tsa coaxial, waveguides, likaroloana tsa transistor, li-tubes tsa microwave, li-tubes tsa hlobo tse se nang letho, le metallurgy ea phofo litanka tsa extrusion.

PTJ® ke moetsi ea ikhethileng ea fanang ka mefuta e fapaneng ea mekoallo ea koporo, likarolo tsa koporo 'me likarolo tsa koporo. Mekhoa e tloaelehileng ea tlhahiso e kenyelletsa ho koala, ho khabisa, ho etsa koporo, terata edm litšebeletso, ho hlohlona, ho bopa le ho kobeha, ho halefisa, ho chesa betloa le ho hatella, ho phunyeletsa le ho otla, ho roala khoele le ho kokota, ho kuta, machining a mangata a spindle, extrusion le tšepe e betlang 'me stamp. Likopo li kenyelletsa mekoallo ea libese, li-conductors tsa motlakase, likhoele tsa coaxial, waveguides, likaroloana tsa transistor, li-tubes tsa microwave, li-tubes tsa hlobo tse se nang letho, le metallurgy ea phofo litanka tsa extrusion.

Re bolelle hanyane ka tekanyetso ea projeke ea hau le nako e lebelletsoeng ea ho fihla. Re tla rera leano la ho fana ka lits'ebeletso tse baballang litšenyehelo ho u thusa ho fihlela sepheo sa hau, O amohelehile ho ikopanya le rona ka kotloloho ( sales@pintejin.com ).

- 5 selekane Machining

- Cnc siloa

- Cnc fetola

- Mechini ea Machining

- Ts'ebetso ea Machining

- Phekolo ea bokaholimo

- Metal Machining

- Machining ea polasetiki

- Phofo Metallurgy hlobo

- Ho Casting

- Likarolo tsa Gallery

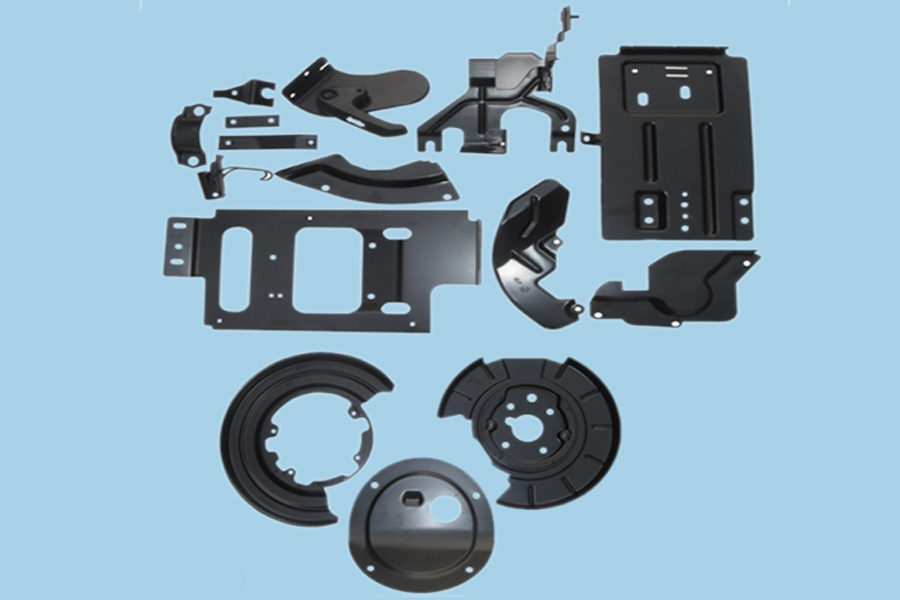

- Likarolo tsa Auto Metal

- Likarolo tsa mechine

- Sesebelisoa sa mocheso oa LED

- Likarolo tsa Kaho

- Likarolo tsa mobile

- Likarolo tsa Bongaka

- Likarolo tsa Elektroniki

- Machining e etselitsoeng

- Likarolo Tsa Baesekele

- Aluminium Machining

- Thaethaniamo Machining

- Lisebelisoa tsa Stainless Steel

- Koporo Machining

- Koporo Machining

- Super motsoako Machining

- Peek Machining

- Machining a UHMW

- Tlanya Machining

- Machining a PA6

- PPS Machining

- Mochini oa Teflon

- Inconel Machining

- Sesebelisoa sa Sesebelisoa sa Steel

- Boitsebiso bo Eketsehileng