Kopo Of Laser Machining Ka mechine Manufacturing

Kopo Of Laser Machining Ka mechine Manufacturing

|

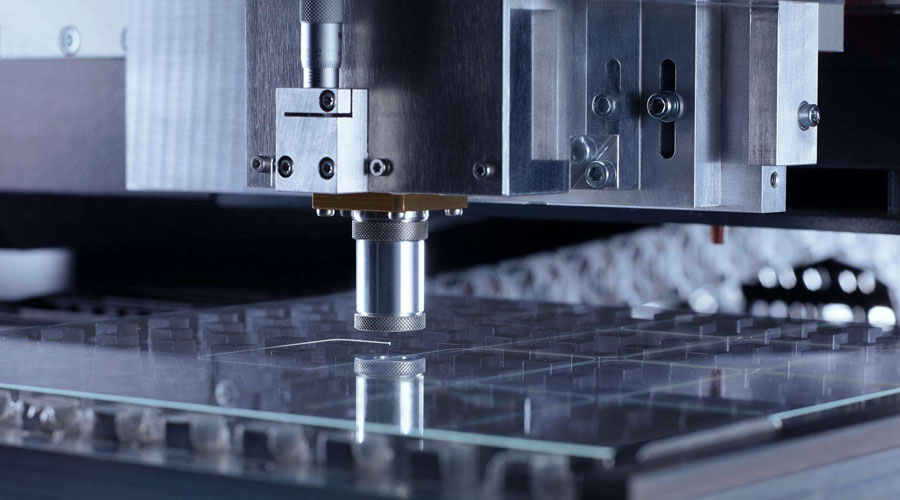

Motsoako oa theknoloji ea laser e sebetsana ke tšebelisano lipakeng tsa toloki ea laser le thepa. E arotsoe ka laser thermal processing le photochemical reaction reaction machining ho latela mekhoa e fapaneng ea machining. Ea pele e sebelisa phello ea mocheso e hlahisoang ke toloki ea laser ho etsa ts'ebetso ea ts'ebetso, mme ea morao e sebelisa letsoalo le phahameng. Li-photon tse nang le matla a mangata li qalisa tšebetso ea lik'hemik'hale ho phethela tšebetso. Le ntlafatso ea laser kopo theknoloji, sebetsa laser e se e le ka sehloohong kopo theknoloji ea litsamaiso tsa laser. E sebelisoa haholo lebaleng la tlhahiso ea mechini mme e bapala karolo ea bohlokoa. |

1.Characteristics ea theknoloji ea laser machining

Ho itšeha la laser ke thekenoloji ya sejwalejwale e kopanyang bohlale le tswelopele, mme e kopanya melawana ya laser, thekenoloji ya CAD le thekenoloji ya taolo ya dipalo. Molao-motheo oa theknoloji ea machining ea laser ke ho bapala karolo ea 'mele holim'a thepa ka lebaka la ts'ebetso e phahameng ea matla a matla a mahlaseli a laser, le ho baka letoto la liphetoho tsa morphological holim'a thepa.

Theknoloji ea machining ea laser e na le melemo ea ho nepahala ho phahameng le ho se na tšilafalo, e ke keng ea lekanngoa le ho fetisoa ke mahlale a mang a ho etsa machining. Ho feta moo, theknoloji ea laser machining e boetse e kopanya mefuta e fapaneng ea litloaelo tse kang lisebelisoa tsa elektronike, lisebelisoa, le ho fetisetsa mocheso oa boenjiniere, ka boemo bo phahameng ba bohlale.

Ha ho bapisoa le mahlale a mang a machining a tlhahiso ea mochini, laser machining e senya thepa e nyane, e na le ts'ebetso e kholo tlhahisong e kholo, 'me e ikamahanya le maemo ho lisebelisoa tse sebetsitsoeng.

E ka sebelisoa bakeng sa tlhahiso ea mechine ea mefuta e fapaneng ea lisebelisoa tse khethehileng, le bakeng sa mechine e meng ea setso Lisebelisoa tse ncha tse ke keng tsa finyelloa ke theknoloji le tsona li sebetsoa ka ho sebelisa theknoloji ea laser machining. Likarolo tsa mantlha tsa theknoloji ea machining ea laser ha ho etsoa mechini:

- (1) Matla a phahameng, thepa e ka qhibilihisoa kapa ea fafatsoa ka nako e khuts'oane kamora ho monya mocheso oa laser, 'me sesebelisoa se ka fetoloa ka potlako leha boemo ba thepa bo phahame.

- (2) Hlooho ea laser e ke ke ea kopana ka kotloloho le mosebetsi, ka hona ho ke ke ha ba le mathata a ho tsofala.

- (3) Eseng feela ts'ebetso ea machining ho li-workpieces tse sa fetoheng, empa le li-workpieces tse tsamaeang, leha lisebelisoa li tiisitsoe ka lintho tse ling.

- (4) Nakong ea machining ea laser, toloki ea laser e laoloa ke komporo ea elektroniki, e ka bonang sebetsa ka ho nepahetseng machining ea mochini, 'me boemo ba ho iketsa bo phahameng.

- (5) Laser machining e ka hlokomela taolo ea mechini, 'me liroboto li ka sebelisoa ho fapana le ho qhekella libakeng tseo ts'ebetso ea batho e leng thata.

2.Application ea tham mong bang laser machining difeme mechine

2.1 Ho sebetsana le thepa

Laser machining ka kakaretso sebelisa kalafo mocheso le holim matlafatsa theknoloji ho sebetsa lintho tse bonahalang tse. Mahlale ana a mabeli a ka futhumatsa bokaholimo ba thepa kapele mme a fetola kapele morpholoji ea eona ha e atamela ntlha e qhibilihang, ka hona e fihlela sepheo sa kalafo holim. Theknoloji ea mochini oa laser ke katoloso ea theknoloji ea setso ea kalafo ea mocheso. Kamora machining a laser, thepa e na le khanyetso e matla ea mokhathala le ho hanyetsa kutu.

Bophelo ba ts'ebeletso le bona bo ekelitsoe, 'me likarolo tsohle tsa ts'ebetso ea thepa li ntlafalitsoe. Ts'ebeliso ea machining ea laser holim'a lisebelisoa tsa mosebetsi e ntlafalitse haholo thepa ea 'mele, e bohlokoa haholo bakeng sa ho ntlafatsa tlholisano ea mmaraka ea lihlahisoa.

Theknoloji ea laser e ka sebelisoa e le 'ngoe kapa e kopantsoe le mahlale a mang ho theha mokhoa o mocha oa ho etsa thepa. Motsoako oa thekenoloji ea laser le thekenoloji ea CAD e butse lefapha le lecha la machining a machining a macha. Theknoloji ea CAD e sebelisa mokhoa oa k'homphieutha ho laola mokhoa oa ho etsa moralo, ho phethela mosebetsi oa moralo oa karolo, ebe o sebelisa theknoloji ea laser ho sebetsa ho latela moralo o hlophisitsoeng oa ho etsa mohlala. Karolo ea mohlala e entsoeng ka theknoloji ea CAD e na le litšobotsi tsa ho nepahala le ho toba, tse ka nolofatsang bothata ba ho etsa likarolo tse rarahaneng.

Haeba mathata a hlaha nakong ea moralo, a ka fetoloa ka nako leha e le efe ho netefatsa botšepehi ba sehlahisoa. Ho etsa mechine ho na le litlhoko tse thata haholo likarolong ka botsona, 'me litlhoko tsa ho nepahala li thata haholo. Ho thata ho lokisa libaka tse ling tse rarahaneng tse kobehileng. Tšebeliso e kopanetsoeng ea theknoloji ea CAD le theknoloji ea laser e ka rarolla bothata bona habonolo, ea fokotsa bothata ba tlhahiso, hape e khutsufatsa potoloho ea R & D ho ntlafatsa katleho ea tlhahiso ea lihlahisoa.

Ho phunya le stamp ke karolo ea bohlokoa ea machining a lintho tse bonahalang. Mefuta e tloaelehileng ea likoti tsa machining e kenyelletsa likoti tsa oli, likoti tse tiisang, likoti tse behang, joalo-joalo. Boleng ba ho sebelisa likoti bo na le tšusumetso e kholo mosebetsing oa karolo. Phello ea ho phunya ea laser machining e molemo ho feta ea ho cheka ka mokhoa o tloaelehileng oa mochine, 'me lebota la lesoba le boreleli ebile le pota-potile, joalokaha ho bontšitsoe Lethathamong la 1. Mokokotlo oa botebo ba sekoti le bophara ba lesoba ka mor'a nako tlas'a laser machining e bontšoa ho Setšoantšo sa 1.

Ho ka bonoa hore nakong ea ts'ebetso ea ho phunya laser, botebo ba sekoti le bophara ba sekoti bo eketsehile haholo sethaleng sa pele, 'me ka ho atolosoa ha nako, Keketseho ea tsona kaofela e ea fokotseha. Lebaka la ho fokotseha ke hore matla a defocusing a laser a fokotsehile, ebe mohloli oa mocheso oa laser o fetoleloa ka hare ho thepa. Ka nako ena, ts'ebetso ea laser

Kopanya le sengoloa sena: Kopo Of Laser Machining Ka mechine Manufacturing

Polelo e Hatisitsoeng: Haeba ho se na litaelo tse ikhethang, lingoloa tsohle tse fumanehang sebakeng sena sa marang-rang ke tsa mantlha. Ka kopo bonts'a mohloli oa khatiso: https: //www.cncmachiningptj.com/ li -ththanks!

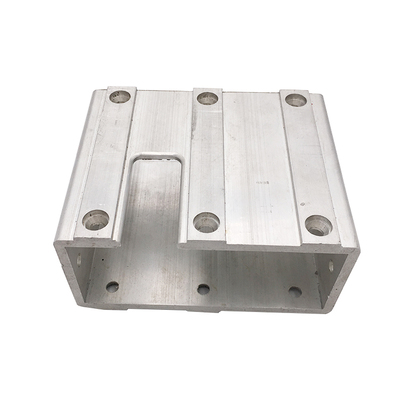

PTJ® e fana ka mefuta e felletseng ea Custom Precision cnc machining china ISO 9001: 2015 & JOALOKAHA-9100 pakiloeng. 3, 4 le 5-axis e nepahetseng ka potlako CNC lisebelisoa lits'ebeletso tse kenyeletsang ho sila, ho fetohela litlhalosong tsa bareki, Lisebelisoa tsa tšepe le tsa polasetiki tse nang le mamello ea +/- 0.005 mm. Litšebeletso tsa bobeli li kenyelletsa CNC le ho sila ho tloaelehileng, ho cheka,shoa ho lahla,lesela la tšepe Ho fana ka mekhoa e metle, tlhahiso e felletseng, tšehetso ea tekheniki le tlhahlobo e felletseng likoloi, aerospace, hlobo le sesebelisoa, mabone a lebisitsoeng,ya kalafi, baesekele, le moreki elektronike liindasteri. Tsamaiso ea nako, re bolelle hanyane mabapi le bajete ea projeke ea hau le nako e lebelletsoeng ea ho tlisa Re tla rera leano la hau ho fana ka lits'ebeletso tse bolokang litšenyehelo ho u thusa ho fihlela sepheo sa hau, Rea u amohela sales@pintejin.com ) ka kotloloho bakeng sa projeke ea hau e ncha.

PTJ® e fana ka mefuta e felletseng ea Custom Precision cnc machining china ISO 9001: 2015 & JOALOKAHA-9100 pakiloeng. 3, 4 le 5-axis e nepahetseng ka potlako CNC lisebelisoa lits'ebeletso tse kenyeletsang ho sila, ho fetohela litlhalosong tsa bareki, Lisebelisoa tsa tšepe le tsa polasetiki tse nang le mamello ea +/- 0.005 mm. Litšebeletso tsa bobeli li kenyelletsa CNC le ho sila ho tloaelehileng, ho cheka,shoa ho lahla,lesela la tšepe Ho fana ka mekhoa e metle, tlhahiso e felletseng, tšehetso ea tekheniki le tlhahlobo e felletseng likoloi, aerospace, hlobo le sesebelisoa, mabone a lebisitsoeng,ya kalafi, baesekele, le moreki elektronike liindasteri. Tsamaiso ea nako, re bolelle hanyane mabapi le bajete ea projeke ea hau le nako e lebelletsoeng ea ho tlisa Re tla rera leano la hau ho fana ka lits'ebeletso tse bolokang litšenyehelo ho u thusa ho fihlela sepheo sa hau, Rea u amohela sales@pintejin.com ) ka kotloloho bakeng sa projeke ea hau e ncha.

- 5 selekane Machining

- Cnc siloa

- Cnc fetola

- Mechini ea Machining

- Ts'ebetso ea Machining

- Phekolo ea bokaholimo

- Metal Machining

- Machining ea polasetiki

- Phofo Metallurgy hlobo

- Ho Casting

- Likarolo tsa Gallery

- Likarolo tsa Auto Metal

- Likarolo tsa mechine

- Sesebelisoa sa mocheso oa LED

- Likarolo tsa Kaho

- Likarolo tsa mobile

- Likarolo tsa Bongaka

- Likarolo tsa Elektroniki

- Machining e etselitsoeng

- Likarolo Tsa Baesekele

- Aluminium Machining

- Thaethaniamo Machining

- Lisebelisoa tsa Stainless Steel

- Koporo Machining

- Koporo Machining

- Super motsoako Machining

- Peek Machining

- Machining a UHMW

- Tlanya Machining

- Machining a PA6

- PPS Machining

- Mochini oa Teflon

- Inconel Machining

- Sesebelisoa sa Sesebelisoa sa Steel

- Boitsebiso bo Eketsehileng