Boemo le tebello ea Laser sebetsa ka ho nepahetseng Machining Technology

Boemo le tebello ea Laser sebetsa ka ho nepahetseng Machining Technology

|

Machining ea lisebelisoa tsa laser e kenyelletsa mefuta e mengata. Sintering, otla ka litebele, ho tšoaea, ho itšeha, ho tjheseletsa, ho fetoloa hoa bokaholimo le phepelo ea mouoane ea lik'hemik'hale kaofela ho nkile tham mong bang laser e le mohloli oa bohlokoa oa matla. |

Lehlaseli la laser le ka tsepamisoa ho saese e nyane haholo, e etsa hore e tšoanelehe haholoholo sebetsa ka ho nepahetseng machining. Re arola mahlale a morao-rao a machining ka likarolo tse tharo ho latela boholo ba sesebelisoa se sebetsitsoeng le litlhoko tse nepahetseng tsa machining:

- Technology Theknoloji ea machining ea Laser bakeng sa lisebelisoa tse kholo, tse nang le lipoleiti tse teteaneng (limilimithara tse 'maloa ho isa ho mashome a limilimithara) e le ntho ea mantlha,' me ho nepahala ha eona ha machining hangata ho maemong a millimeter kapa sub-millimeter;

- Technology Theknoloji ea machining ea laser e nepahetseng, e nang le lipoleiti tse tšesaane (0.1 ho ea ho 1.0mm) e le sesebelisoa se ka sehloohong sa machining, 'me ho nepahala ha eona ha machining hangata ho latela tatellano ea li-microns tse leshome;

- Technology Theknoloji ea Laser microfabrication, bakeng sa lifilimi tse fapaneng tse nang le botenya bo ka tlase ho 100μm e le ntho e ka sehloohong ea machining, ho nepahala ha eona ha machining hangata ho ka tlase ho li-microns tse 10 kapa esita le boemo ba sub-micron.

Re lokela ho hlokomela hore indastering ea mechini, ho nepahala hangata ho bolela ho ba bohale bo nyane le sebaka se fokolang sa mamello (ho kenyeletsoa boemo, sebopeho, boholo, jj.). Leha ho le joalo, poleloana "ho nepahala" sengoloeng sena e supa lekhalo le lenyane sebakeng se ntseng se sebetsoa, ho bolelang hore boholo ba moeli bo ka sebetsoang bo nyane. Mefuteng e meraro e kaholimo ea lisebelisoa tsa laser, mahlale a laser machining a likarolo tse kholo a se a holile haholo mme boemo ba indasteri bo bile holimo haholo. tham mong bang laser theknoloji e machining tse kang tham mong bang laser kuta, tham mong bang laser sebetsa ka ho nepahetseng mananose, tham mong bang laser theknoloji ea ho ngola e boetse e se e ho pharaletseng sebelisoa indastering, 'me ho na le litlaleho tse ngata tse amanang. Sengoliloeng sena se tla shebana le mahlale a machining a nepahetseng ka laser. Molemong oa boiketlo, lipheo tsa machining tsa mochini o nepahetseng o boletsoeng ka tlase li lekantsoe ho lipoleiti tse tšesaane (0.1-1.0mm).

1 .Caparison pakeng tsa machining tham mong bang laser sebetsa ka ho nepahetseng le mekhoa ea setso machining

Ka tsoelo-pele ea mahlale a morao-rao, mefuta ea theknoloji e nepahetseng ea machining e ntse e eketseha haholo.

Laser sebetsa ka ho nepahetseng machining na le latelang makgetheng bohlokoa:

- Boemo ba machining bo nepahetseng ba laser bo pharalletse, ho kenyeletsoa le lisebelisoa tsohle tsa tšepe le tse seng tsa tšepe. Ha machining ea elektrolytic e ka sebetsana feela le thepa e tsamaisang thepa, machining ea photochemical e loketse feela lisebelisoa tse senyehang habonolo, 'me machining ea plasma e thata ho sebetsana le lisebelisoa tse ling tse phahameng tsa ho qhibiliha.

- ② Ho na le lintlha tse 'maloa tse susumetsang boleng ba machining ea laser e nepahetseng,' me ho nepahala ha machining ho phahame, 'me ka kakaretso ho molemo ho feta mekhoa e meng ea moetlo oa machining ka kakaretso.

- Ho ea ka pono ea potoloho ea machining, sesebelisoa sa eleketrode sa EDM se hloka ho nepahala ho phahameng, tahlehelo e kholo, le potoloho e telele ea machining; moralo oa hlobo ea cathode bakeng sa lehare la machining le profil ea machining ea electrolytic e kholo, mme potoloho ea tlhahiso e boetse e telele; Mekhoa ena e rarahane; mochini oa laser o nepahetseng o bonolo, bophara ba sekhahla bo bonolo ho bo fetola le ho bo laola, lebelo la machining le potlakile, mme potoloho ea machining e khuts'oane ho feta mekhoa e meng.

- ④Laser machining sebetsa ka ho nepahetseng ke ea machining bao e seng ho ikopanya, ntle le matla a ho phetha molao feela. Ha e bapisoa le ts'ebetso ea EDM le plasma ea arc, mocheso oa eona o amehileng ka mocheso le phetoho e nyane haholo, ka hona e ka sebetsana le likarolo tse nyane haholo.

Ka kakaretso, theknoloji e nepahetseng ea machining ea laser e na le menyetla e mengata ho feta mekhoa ea moetlo oa machining, mme tebello ea eona ea ts'ebeliso e pharalletse haholo.

2. Selelekela ho lisebelisoa tsa machining tse sebelisoang haholo ka laser

Li-laser tse atisang ho sebelisoa bakeng sa ho sebetsa ka mokhoa o nepahetseng li kenyelletsa: lisebelisoa tsa CO2 lasers, YAG lasers, copper vapor lasers, excimer lasers, le CO lasers, joalo-joalo.

Har'a tsona, li-lasers tsa CO2 tse nang le matla a phahameng le lisebelisoa tse phahameng tsa YAG li sebelisoa haholo ka theknoloji e kholo ea mochine oa laser; laser vapor lasers le excimer lasers li sebelisoa haholo ho theknoloji ea laser micro-machining; Li-lasers tsa YAG tse mahareng le tse tlase hangata li sebelisoa bakeng sa mochini o nepahetseng.

3. Ts'ebeliso ea machining e nepahetseng ea laser le nts'etsopele ea China le machabeng

3.1 Boemo ba machabeng

3.1.1 Laser ho cheka ka nepo

Ka tsoelo-pele ea mahlale a morao-rao, mokhoa o tloaelehileng oa ho phunya ha o khone ho fihlela litlhoko makhetlo a mangata. Mohlala, masoba a manyane a bophara ba li-micrometer tse mashome a 'maloa a sebetsoa ka lits'epe tse thata tsa tungsten carbide; masoba a tebileng a nang le bophara ba li-micrometer tse makholo a 'maloa a sebetsoa ka bofubelu bo thata le bo bobebe le safire, jj., e ke keng ea fihlelleha ka mekhoa e tloaelehileng ea machining. Matla a ts'oanang a matla a laser a holimo ho 108 W / cm2, e ka futhumatsang thepa ho fihlela e qhibiliha kapa e belang ka nako e khuts'oane ho fihlela pherekano linthong tse kaholimo. Ha ho bapisoa le toloki ea elektronike, motlakase, tlhase ea motlakase le ho cheka ka metjhini, ho cheka ka laser ho na le boleng bo botle, ho pheta-pheta ho pheta-pheta, ho tenyetseha ho matla, ts'ebetso e phahameng, theko e tlase, le melemo ea bohlokoa ea theknoloji le moruo. Machaba sebetsa ka ho nepahetseng laser ho cheka e se e fihlile boemong bo phahameng haholo. Khamphani ea Switzerland e sebelisa li-lasers tse tiileng ho phunya masoba ka lehare la sefofane, le ka sebetsanang le li-microholes tse nang le bophara ho tloha ho 20 μm ho isa ho 80 μm, mme karolelano ea bophara ho ea botebo e ka fihla 1:80 (sheba Setšoantšo sa 1 (a)) . Leballo la laser le ka sebetsana le masoba a fapaneng a sebopeho se ikhethileng joalo ka masoba a foufetseng (bona Setšoantšo sa 1 (b)) le masoba a lisekoere linthong tse robehileng joalo ka letsopa, tse ke keng tsa fihlelleha ka mochini o tloaelehileng.

3.1.2 Laser itšeha sebetsa ka ho nepahetseng

Ha ho bapisoa le mokhoa o tloaelehileng oa ho itšeha, ho nepahala ho khaola laser e na le menyetla e mengata. Mohlala, e ka etsa likhahla tse moqotetsane, hoo e ka bang ha ho na masala a ho itšeha, libaka tse nyane tsa mocheso tse amehang, lerata le tlase la ho itšeha, 'me e ka boloka 15% ho 30% ea thepa. Hobane laser ha e hlahise tšusumetso ea mochini le khatello ea thepa e sehiloeng, e loketse ho seha lisebelisoa tse thata le tse bobebe joalo ka khalase, letsopa le semiconductors. a loketse bakeng sa likarolo tse nyenyane. Mofuta oa ho itšeha sebetsa ka ho nepahetseng. Khamphani ea Switzerland e sebelisa li-lasers tsa mmuso o tiileng bakeng sa ho itšeha ka nepo, 'me ho nepahala ha eona ha sebopeho ho fihlile boemong bo phahameng haholo.

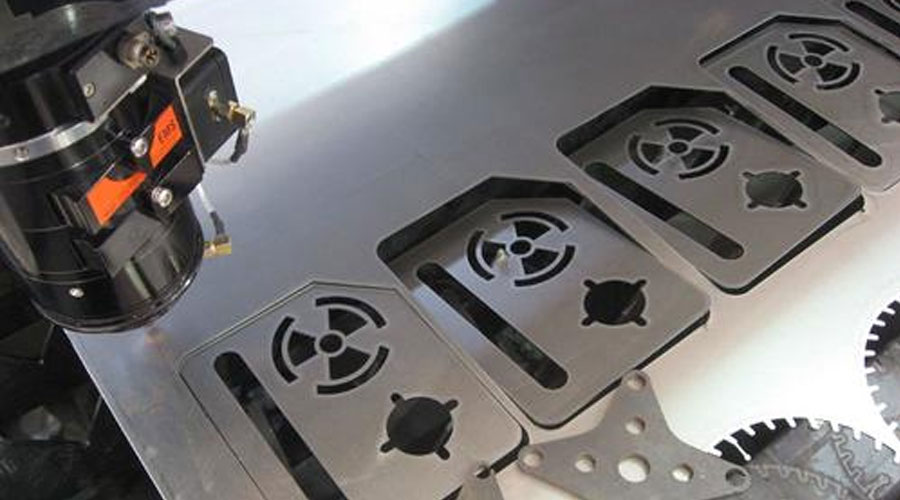

Mokhoa o tloaelehileng oa ho itšeha ka laser ke ho seha li-stencil tsa SMT ka liboto tsa lipotoloho tse hatisitsoeng (sheba Setšoantšo sa 2). Mokhoa oa khale oa machining oa template ea SMT ke mokhoa oa ho kenya lik'hemik'hale. Bofokoli ba eona bo bolaeang ke hore tekanyo e lekantsoeng ea mochine ha ea lokela ho ba ka tlase ho botenya ba poleiti, 'me mokhoa oa ho kopanya lik'hemik'hale o na le mokhoa o rarahaneng, potoloho e telele ea mochine, le mokhoa o senyang o silafatsa tikoloho.

Ho sebelisa laser machining ho ke ke ha hlola mefokolo ena feela, empa hape le ho sebelisa template e phethiloeng. Ka ho khetheha, ho nepahala ha machining le lekhalo la lekhalo li molemo haholo ho feta tsa pele (bona setšoantšo sa 3). E tlase hanyane ho feta ea pele. Leha ho le joalo, ka lebaka la boitsebiso bo phahameng ba theknoloji ea sete eohle ea thepa e sebelisoang bakeng sa mochine oa laser le theko e phahameng, ke lik'hamphani tse seng kae feela linaheng tse seng kae tse kang United States, Japane le Jeremane tse ka hlahisang mochine oohle.

3.1.3 Laser tjheseletsa sebetsa ka ho nepahetseng

Laser welding e na le sebaka se moqotetsane se anngoeng ke mocheso le seam e nyane ea weld. Ka ho khetheha, e ka kopanya lisebelisoa tse phahameng tsa ho qhibiliha le lisebelisoa tse sa tšoaneng ntle le tlhoko ea lisebelisoa tse ling. Ts'ebeliso ea machabeng ea li-lasers tse tiileng tsa YAG bakeng sa ho tjheseletsa seam le ho tjheseletsa ka letheba e fihlile boemong bo phahameng. Ntle le moo, lithapo tse etellang pele tsa potoloho e hatisitsoeng li entsoe ka laser, e sa hlokeng ts'ebeliso ea ts'ebetsong, mme e ka fokotsa ts'oaetso e futhumetseng ntle le ho ama lefu la potoloho, ka hona ea netefatsa boleng ba setereke se kopaneng (bona Setšoantšo sa 4) .

3.2 Boemo ba hajoale Chaena

Ka mor'a lilemo tse fetang 20 tsa boiteko, mabapi le theknoloji ea laser precision machining le lisebelisoa tse feletseng, le hoja Chaena e 'nile ea sebelisoa ka ceramic laser scribing le laser spot welding ea likaroloana tse nyenyane tsa tšepe, seam welding le air-tight welding, le ho tšoaea, etc.

Leha ho le joalo, ho thekenoloji ea machining ea laser e nepahetseng, mokhoa o nepahetseng oa ho seha template ea microelectronic circuit e nang le litaba tse phahameng tsa tekheniki le 'maraka o pharaletseng oa' maraka, likoti, masoba a foufetseng le masoba a nang le sebōpeho se khethehileng, likoti tsa litlhaloso le boholo bo fapaneng maqepheng a ceramic le ho hatisoa. liboto tsa potoloho Laser ho nepahala machining le likarolo tse ling li ntse li le sethaleng sa lipatlisiso le nts'etsopele, 'me ha ho na mohlala oa indasteri o hlahang.

Bongata ba basebelisi ba China ka kakaretso ba sebelisa litempele tse tsoang kantle ho naha kapa ho etsa machining Hong Kong le libakeng tse ling. Theko e holimo le nako e telele e amme haholo potoloho ea ntlafatso ea sehlahisoa. Lilemong tsa morao tjena, lik'hamphani tse 'maloa tse kholo tsa machabeng li bone' maraka o moholo oa China indastering ea machining ea laser. , E se e qalile ho theha makala Chaena. Leha ho le joalo, litšenyehelo tse phahameng tsa mochini li eketsa litšenyehelo tsa sehlahisoa mme li ntse li etsa hore likhoebo tse ngata li ba nyahamise.

4. Mokhoa oa Nts'etsopele le tebello ea Laser Precision Machining Technology

Li-lasers tsa boleng bo holimo, tse sebetsang hantle, tse tsitsitseng, tse ka tšeptjoang le tse theko e tlaase ke lintho tse hlokahalang bakeng sa nts'etsopele le ts'ebeliso ea machining a nepahetseng. E 'ngoe ea mekhoa ea nts'etsopele ea machining ea laser precision ke miniaturization ea litsamaiso tsa machining. Lilemong tsa morao tjena, li-laser tsa diode pumped li tsoetse pele ka potlako. E na le letoto la melemo e kang ts'ebetso e phahameng ea ho sokoloha, botsitso bo botle ba mosebetsi, boleng bo botle ba mahlaseli, le boholo bo fokolang. Ho ka etsahala hore ebe laser e ka sehloohong bakeng sa moloko o latelang oa laser precision machining.

Ho kopanngoa ha litsamaiso tsa machining ke mokhoa o mong oa bohlokoa ho nts'etsopele ea laser precision machining. Ho hlophisa le ho ntlafatsa theknoloji ea machining ea laser bakeng sa lisebelisoa tse fapaneng; ntshetsapele mananeo a taolo a bonolo, a inehetseng a loketseng bakeng sa machining a laser precision, le ho e tlatselletsa ka polokelongtshedimosetso e tsamaellanang le yona; kopanya taolo, ts'ebetso le laser ho fihlela optical, Ho kopanngoa ha mochine, motlakase le lisebelisoa tsa thepa ke mokhoa o ke keng oa qojoa ho nts'etsopele ea laser precision machining.

Leha China e na le lekhalo le leholo le machabeng mabapi le mahlale a machining a laser le lisebelisoa, haeba re ntse re tsoela pele ho ntlafatsa boleng ba laser toloki le ho nepahala ha machining ho ipapisitse le ea mantlha, ho kopantsoe le lipatlisiso tsa mahlale a machining, re tla nka laser sebetsa ka ho nepahetseng 'maraka oa machining ka hohle kamoo ho ka khonehang. Butle-butle kenella tšimong ea laser-machining ea laser, e ka khothaletsa nts'etsopele e potlakileng ea ho khaola laser theknoloji, 'me qetellong etsa machining sebetsa ka ho nepahetseng ka laser ho indasteri e khōlō.

Kopanya le sengoloa sena: Boemo le tebello ea Laser sebetsa ka ho nepahetseng Machining Technology

Polelo e Hatisitsoeng: Haeba ho se na litaelo tse ikhethang, lingoloa tsohle tse fumanehang sebakeng sena sa marang-rang ke tsa mantlha. Ka kopo bonts'a mohloli oa khatiso: https: //www.cncmachiningptj.com/ li -ththanks!

PTJ® e fana ka mefuta e felletseng ea Custom Precision cnc machining china ISO 9001: 2015 & JOALOKAHA-9100 pakiloeng. 3, 4 le 5-axis e nepahetseng ka potlako CNC lisebelisoa lits'ebeletso tse kenyeletsang ho sila, ho fetohela litlhalosong tsa bareki, Lisebelisoa tsa tšepe le tsa polasetiki tse nang le mamello ea +/- 0.005 mm. Litšebeletso tsa bobeli li kenyelletsa CNC le ho sila ho tloaelehileng, ho cheka,shoa ho lahla,lesela la tšepe 'me stampHo fana ka lipapatso, tlhahiso e felletseng, tšehetso ea tekheniki le tlhahlobo e felletseng likoloi, aerospace, hlobo le sesebelisoa, mabone a lebisitsoeng,ya kalafi, baesekele, le moreki elektronike liindasteri. Tsamaiso ea nako, re bolelle hanyane mabapi le bajete ea projeke ea hau le nako e lebelletsoeng ea ho tlisa Re tla rera leano la hau ho fana ka lits'ebeletso tse bolokang litšenyehelo ho u thusa ho fihlela sepheo sa hau, Rea u amohela sales@pintejin.com ) ka kotloloho bakeng sa projeke ea hau e ncha.

PTJ® e fana ka mefuta e felletseng ea Custom Precision cnc machining china ISO 9001: 2015 & JOALOKAHA-9100 pakiloeng. 3, 4 le 5-axis e nepahetseng ka potlako CNC lisebelisoa lits'ebeletso tse kenyeletsang ho sila, ho fetohela litlhalosong tsa bareki, Lisebelisoa tsa tšepe le tsa polasetiki tse nang le mamello ea +/- 0.005 mm. Litšebeletso tsa bobeli li kenyelletsa CNC le ho sila ho tloaelehileng, ho cheka,shoa ho lahla,lesela la tšepe 'me stampHo fana ka lipapatso, tlhahiso e felletseng, tšehetso ea tekheniki le tlhahlobo e felletseng likoloi, aerospace, hlobo le sesebelisoa, mabone a lebisitsoeng,ya kalafi, baesekele, le moreki elektronike liindasteri. Tsamaiso ea nako, re bolelle hanyane mabapi le bajete ea projeke ea hau le nako e lebelletsoeng ea ho tlisa Re tla rera leano la hau ho fana ka lits'ebeletso tse bolokang litšenyehelo ho u thusa ho fihlela sepheo sa hau, Rea u amohela sales@pintejin.com ) ka kotloloho bakeng sa projeke ea hau e ncha.

- 5 selekane Machining

- Cnc siloa

- Cnc fetola

- Mechini ea Machining

- Ts'ebetso ea Machining

- Phekolo ea bokaholimo

- Metal Machining

- Machining ea polasetiki

- Phofo Metallurgy hlobo

- Ho Casting

- Likarolo tsa Gallery

- Likarolo tsa Auto Metal

- Likarolo tsa mechine

- Sesebelisoa sa mocheso oa LED

- Likarolo tsa Kaho

- Likarolo tsa mobile

- Likarolo tsa Bongaka

- Likarolo tsa Elektroniki

- Machining e etselitsoeng

- Likarolo Tsa Baesekele

- Aluminium Machining

- Thaethaniamo Machining

- Lisebelisoa tsa Stainless Steel

- Koporo Machining

- Koporo Machining

- Super motsoako Machining

- Peek Machining

- Machining a UHMW

- Tlanya Machining

- Machining a PA6

- PPS Machining

- Mochini oa Teflon

- Inconel Machining

- Sesebelisoa sa Sesebelisoa sa Steel

- Boitsebiso bo Eketsehileng