Ho lemoha mokhoa oa ho khefutsa ka likarolo tsa machining tsa PEEK

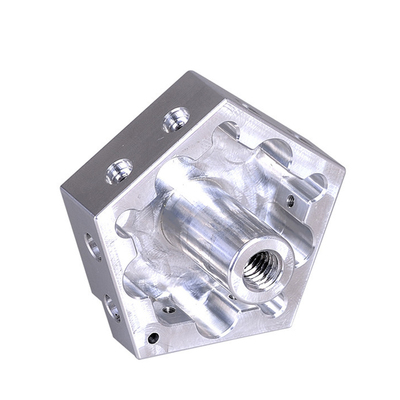

Selelekela le tšoantšetso ea bonngoe

|

1. Coaxiality ke mochini o sebelisang theknoloji o emelang maemo a mamello ka sebopeho le mamello ea maemo a likarolo. Lintlha tse amehang ke selepe le selepe, lesoba le sekoti, le selekane le lesoba. Ho hlokahala mola o tšoanang o otlolohileng kapa ho tsepamisa mohopolo, ho bolelang ho laola hore na axis ea 'nete e kheloha hakae ho axis ea litšupiso! 2. Letšoao la eona le hlahisoa e le selikalikoe se habeli: ◎ |

Litlamorao tse ka bang teng tsa liphoso tse kholo tsa coaxiality

Phoso ea Coaxiality ke ho se hlophise hantle hoa setsi sa selikalikoe se bonts'itsoeng karolong ea sefapano. Haeba likarolo tse nang le liphoso tse kholo tsa coaxiality li kentsoe le ho sebelisoa, li kanna tsa se bokelloe nakong ea kopano. Mochini o kopaneng o ka hlahisa ho sisinyeha, ho tsitsinyeha, lerata la nako le nako, ho hula ho sa tsitsang, tšenyo ea likarolo tsa mochini, mme ho ka baka tšenyo e mpe. Letoto la mathata a mochini o joalo ka likotsi tsa polokeho, ka hona taolo ea coaxiality ea likarolo esale e le ntho ea bohlokoa ea tlhahlobo ea boleng ba PTJ Shop Plastics Machining.

Mefuta ea likarolo tsa tekanyo ea coaxiality

Tekanyo ea concentricity e tlameha ho etsoa ka likarolo tse potolohang, joalo ka thekos, Lisebelisoas, Bushings le likarolo tse ling.Thepa ea liteko

Ho thata ho lekanya coaxiality. Lisebelisoa tseo re li sebelisang li kenyelletsa litšoantšo, likhokahanyo tse tharo, limithara tse khelohileng, litšepe tse bopehileng joaloka V, litsupa tsa ho daela le tse khethehileng lihlopha.

Mekhoa ea ho lekanya

Tlhaloso ea coaxiality ke ntho ea teko eo re atisang ho e etsa mosebetsing oa litekanyo. Se latelang ke kenyelletso e khuts'oane ea mochini le lisebelisoa tse hlahisoang ke k'hamphani.

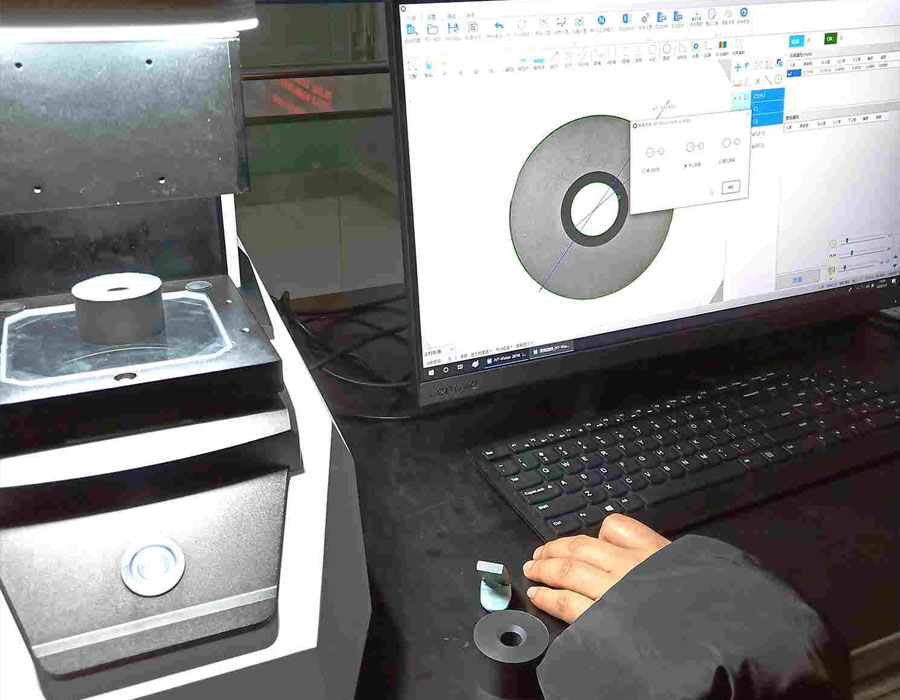

Mokhoa oa ho lekanya khokahano le setšoantšo

- 1. Tlosa komporo ebe u beha karolo e lekiloeng bencheng ea mosebetsi

- 2. Bula halima konopo ka khomphuteng le ho kenya lenaneo

- 3. Tobetsa selikalikoe se kantle le lesoba le kahare la ntho e lekantsoeng ka toeba, ebe u tobetsa konopo ea ho lekanya

- 4. Bala tlhaiso-leseling ea coaxiality, e tlalehe, 'me u tlatse tlaleho ea liteko!

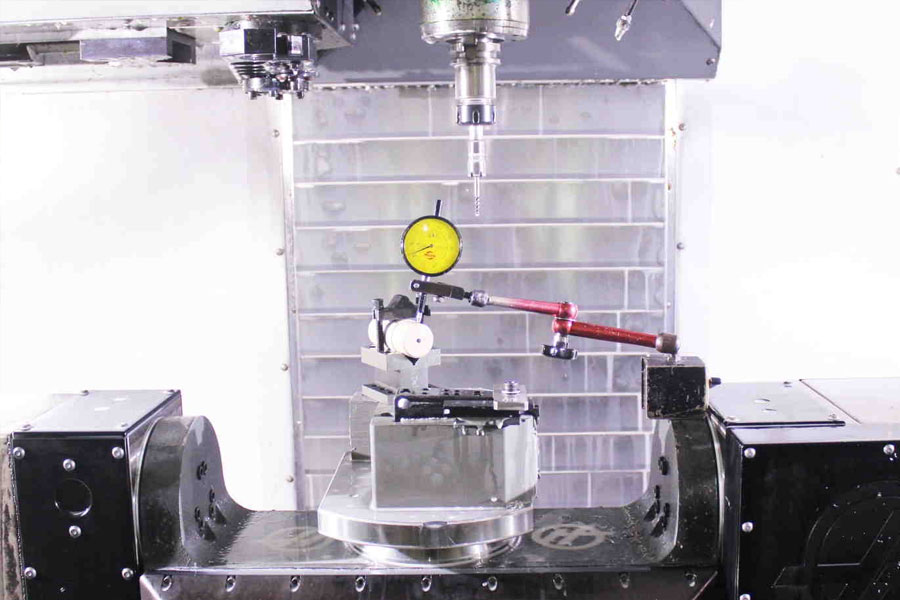

2. Mokhoa oa ho lekanya khokahano le likhokahano tse tharo (CMM)

- 1. Khetholla setšoantšo pele 'me u fumane benche.

- 2. Lokisa file ea Peek machining Karolo e lokelang ho lekanyetsoa sethaleng sa khokahano e meraro ebe ee lokisa ka thata.

- 3. Bulela likhokahano tse tharo, lekanya hlooho, bulela komporo, fumana software e lekanang e lekanang, bula software, ebe u kenya lenaneo.

- 4. Qala ho lekanya lihlahisoa, theha tsamaiso ea khokahano, 'me u lekanye selikalikoe se kantle.

- 5. Hlalosa seelo, lekola diselennere tse lekantsweng, mme o ka bona coaxiality.

- 6. Romela kantle ho naha tlaleho ea liteko.

3.Mekhoa ea ho metha coaxiality le yaw

- 1. Hlatsoa sekhechana sa liteko ka metsi a futhumetseng ebe u se hlakola ka lesela le ommeng.

- 2. Fetola sebaka se pakeng tsa malebela a mabeli a yaw, e leng khuts'oane ho 8 mm ho feta karolo ea shaft e lokelang ho metoa. Lumellanya lesoba le bohareng la pheletsong ea sekhechana sa teko le ntlha e tsitsitseng ea kotulo. Hula workpiece ka letsoho la hau le letšehali 'me u hatelle ho kheloha ka letsoho la hao le letona. Sebopeho sa ntlha e tsamaeang pheletsong e 'ngoe ea pendulum se etsa hore ntlha e tsamaeang e fokotsehe. Matsoho a ka letsohong le letšehali le le letona a sebelisana hantle, 'me a sutumelletsa ntlha e tsamaeang ka sekoting se bohareng ntlheng e' ngoe ea mosebetsi!

- 3. Potoloha ntho hore e lekoe ka letsoho, 'me u e fetole habonolo, empa lekhalo ha lea lokela ho ba le leholo haholo. Etsa bonnete ba hore ntho e thata. Ho seng joalo e tla baka liphetho tse sa nepahalang tsa liteko. Haeba o hloka ho fetola ho tjeka, ka kopo sheba Article 2 kaholimo

- 4 kenya lets'oao la ho daela, botlaaseng, le ho ema, 'me u lokise sesupo sa ho daela e le hore probe e kopane le bokaholimo bo lekantsoeng ba kantle ho mosebetsi,' me ho na le khatello ea selikalikoe sa 0.5-1.

- 5. Butle-butle 'me ka mokhoa o ts'oanang u potolohe sekhechana sa mosebetsi ka letsoho beke e le' ngoe, 'me u bone ho fetoha hoa sesupo sa ho daela, nka phapang lipakeng tsa' Mmax e balang le Mimin e balang e le phoso ea coaxiality ea karolo eo, 'me u tlalehe data.

- 6. Tsamaisa bracket ea lets'oao la ho daela, khetha selikalikoe se kantle, potoloha karolo e lokelang ho metoa, 'me u lekanye maemo a mane a fapaneng ho latela mokhoa o hlalositsoeng kaholimo. Nka boleng ba MAX ba phapang lipakeng tsa ho bala Mmax le Mimin ea ho bala e le phoso ea karolo ea Coaxiality.

- 7. Tlatsa tlaleho ea liteko 'me u hlophise lisebelisoa tsa liteko.

4. Mokhoa oa ho fumana ts'ebelisano 'moho ka tšepe e bopehileng joaloka V

- 1. Hlatsoa sekhechana sa liteko ka metsi a futhumetseng ebe u se hlakola ka lesela le ommeng.

- 2. Lokisetsa li-block tse peli tse bōpehileng joaloka V tse nang le bolelele bo lekanang le bohale bo lekanang. Beha liboloko tse lokisitsoeng tse bopehileng joaloka V holim'a letlapa la 'mabole kapa tafoleng ea mochini o bataletseng.

- 3. Beha palo ea mosebetsi o tla hlahlojoa mosikong oa V oa seletsa

- 4. Kenya gauge ea ho daea, setsi sa tafole le seemo sa metara, lokisa gauge ea ho daela e le hore probe e kopane le bokaholimo bo lekantsoeng ba kantle ho mosebetsi, mme ho na le khatello ea selikalikoe sa 0.5 --- 1

- 5. Tobetsa fatše ka matsoho 'me butle-butle le ka mokhoa o ts'oanang u potolohe sehlahisoa bakeng sa beke e le' ngoe, 'me u bone ho fetoha ha sesupo sa ho daela, nka phapang lipakeng tsa ho bala Mmax le ho bala Mimin e le phoso ea coaxiality ea karolo ebe u rekota data.

- 6. Ebe u suthisa setsi sa tafole, khetha selikalikoe se kantle, potoloha karolo e lokelang ho metoa, lekanya maemo a mane a fapaneng ho latela mokhoa o kaholimo, 'me u nke boleng ba MAX phapang lipakeng tsa ho bala Mmax le Mimin ea ho bala joalo ka eona. Phoso ea Axiality

- 7. Tlatsa tlaleho ea liteko 'me u hlophise lisebelisoa tsa liteko.

5. Mokhoa oa ho fumana ts'ebelisano-'moho ea lithulusi tse khethehileng

Mokhoa oa ho bala lintlha le ho tlatsa ho tlatsa

- 1. Pele bala palo ea phoso ea coaxiality karolong e le 'ngoe ea litekanyo, ke hore, Δ = Mmax-Mmin.

- 2. Nka boleng ba MAX ba boleng ba phoso ea coaxiality bo lekantsoeng karolong ka 'ngoe e le phoso ea coaxiality ea karolo eo.

- 3. Tlatsa tekanyo ho latela mehato e kaholimo 'me u tlatse tlhaiso-leseling e nepahetseng le liphetho tsa litekanyo tsa DUT tlalehong e lekanang ea liteko,' me u e sebelise e le mokhoa oa ho supa hore na phoso ea bokopane ba karolo eo ea amoheleha.

Kopanya le sengoloa sena: Ho lemoha mokhoa oa ho khefutsa ka likarolo tsa machining tsa PEEK

Polelo e Hatisitsoeng: Haeba ho se na litaelo tse ikhethang, lingoloa tsohle tse fumanehang sebakeng sena sa marang-rang ke tsa mantlha. Ka kopo bonts'a mohloli oa khatiso: https: //www.cncmachiningptj.com/ li -ththanks!

PTJ® e fana ka mefuta e felletseng ea Custom Precision cnc machining china ISO 9001: 2015 & JOALOKAHA-9100 pakiloeng. 3, 4 le 5-axis e nepahetseng ka potlako CNC lisebelisoa lits'ebeletso tse kenyeletsang ho sila, ho fetohela litlhalosong tsa bareki, Lisebelisoa tsa tšepe le tsa polasetiki tse nang le mamello ea +/- 0.005 mm. Litšebeletso tsa bobeli li kenyelletsa CNC le ho sila ho tloaelehileng, ho cheka,shoa ho lahla,lesela la tšepe 'me stampHo fana ka lipapatso, tlhahiso e felletseng, tšehetso ea tekheniki le tlhahlobo e felletseng likoloi, aerospace, hlobo le sesebelisoa, mabone a lebisitsoeng,ya kalafi, baesekele, le moreki elektronike liindasteri. Tsamaiso ea nako, re bolelle hanyane mabapi le bajete ea projeke ea hau le nako e lebelletsoeng ea ho tlisa Re tla rera leano la hau ho fana ka lits'ebeletso tse bolokang litšenyehelo ho u thusa ho fihlela sepheo sa hau, Rea u amohela sales@pintejin.com ) ka kotloloho bakeng sa projeke ea hau e ncha.

PTJ® e fana ka mefuta e felletseng ea Custom Precision cnc machining china ISO 9001: 2015 & JOALOKAHA-9100 pakiloeng. 3, 4 le 5-axis e nepahetseng ka potlako CNC lisebelisoa lits'ebeletso tse kenyeletsang ho sila, ho fetohela litlhalosong tsa bareki, Lisebelisoa tsa tšepe le tsa polasetiki tse nang le mamello ea +/- 0.005 mm. Litšebeletso tsa bobeli li kenyelletsa CNC le ho sila ho tloaelehileng, ho cheka,shoa ho lahla,lesela la tšepe 'me stampHo fana ka lipapatso, tlhahiso e felletseng, tšehetso ea tekheniki le tlhahlobo e felletseng likoloi, aerospace, hlobo le sesebelisoa, mabone a lebisitsoeng,ya kalafi, baesekele, le moreki elektronike liindasteri. Tsamaiso ea nako, re bolelle hanyane mabapi le bajete ea projeke ea hau le nako e lebelletsoeng ea ho tlisa Re tla rera leano la hau ho fana ka lits'ebeletso tse bolokang litšenyehelo ho u thusa ho fihlela sepheo sa hau, Rea u amohela sales@pintejin.com ) ka kotloloho bakeng sa projeke ea hau e ncha.

- 5 selekane Machining

- Cnc siloa

- Cnc fetola

- Mechini ea Machining

- Ts'ebetso ea Machining

- Phekolo ea bokaholimo

- Metal Machining

- Machining ea polasetiki

- Phofo Metallurgy hlobo

- Ho Casting

- Likarolo tsa Gallery

- Likarolo tsa Auto Metal

- Likarolo tsa mechine

- Sesebelisoa sa mocheso oa LED

- Likarolo tsa Kaho

- Likarolo tsa mobile

- Likarolo tsa Bongaka

- Likarolo tsa Elektroniki

- Machining e etselitsoeng

- Likarolo Tsa Baesekele

- Aluminium Machining

- Thaethaniamo Machining

- Lisebelisoa tsa Stainless Steel

- Koporo Machining

- Koporo Machining

- Super motsoako Machining

- Peek Machining

- Machining a UHMW

- Tlanya Machining

- Machining a PA6

- PPS Machining

- Mochini oa Teflon

- Inconel Machining

- Sesebelisoa sa Sesebelisoa sa Steel

- Boitsebiso bo Eketsehileng