CNC Machining Theknoloji ea Tiisitsoe Pipe Taper Thread

CNC Machining Theknoloji ea Tiisitsoe Pipe Taper Thread

|

The CNC lisebelisoa thekenoloji ea ho tiisa likhoele tsa phala ea phala e tšohloa, litekanyetso tsa hona joale tsa likhoele tsa liphaephe tsa Sechaena li hlalositsoe, litšoaneleho, tlhahlobo ea ts'ebetso le moralo oa lenaneo la likhoele tsa ho tiisa liphaephe li hlalositsoe ka botlalo, 'me ts'ebetso e kopantsoe le mehlala e tobileng. Theknoloji e hlahlobiloe ka mokhoa o hlophisitsoeng molemong oa ho fana ka litšupiso bakeng sa litlhoko tsa mekha e amehang. |

Ho tiisa khoele ea phala ea liphaephe hona joale ke mokhoa o sebetsang haholoanyane oa ho hokahanya ha pipe taper, e sebelisoang butle-butle nakong ea ho tsamaisa metsi le ho tiisa khase. E le hore u ntlafatse ka ho eketsehileng boleng ba khokahanyo ea liphaephe tsa tiiso, ho hlokahala hore u etse ts'ebetso ea ho laola lipalo holim'a khoele ea phala ea pipe, e hlokang hore re amohele theknoloji e sebetsang ho etsa mosebetsi o tšoanang. Ho latela sena, sengoloa sena se bua ka theknoloji ea machining ea CNC ea khoele e tiisitsoeng ea phala ea 55 °, eo ho lumeloang hore e thusa litlhoko tsa mekha e amanang.

1. Litšobotsi tse sebetsang tsa khoele ea phala e tiisitsoeng ea 55 °

Ka khoele ea pipe e tiisitsoeng ea 55 °, ha ho hlokahale hore u kenye sealant leha e le efe, e ka thibelang ka katleho ho tsoa ha sealant. Likhoele tse ka har'a lithapo tse tiisitsoeng tsa khoele li arotsoe ka likhoele tse ka hare tsa cylindrical le likhoele tse ka ntle tsa conical. Ha khatello e le tlase ho feta 5 × 105MPa, khoele ea ka hare ea cylindrical e ka sebelisoa bakeng sa ho hokahanya, e le hore mohokahanyo o be thata haholo; ha khoele e ka ntle ea conical e atisa ho sebelisoa tlas'a mocheso o phahameng le khatello e phahameng. Mofuta ona oa khoele o loketse ho sebelisoa liphaepheng, likokong le lisebelisoa tse ling tse kopantsoeng ke likhoele, 'me ho tiisoa ha eona ho molemo haholo,' me hangata ho sebelisoa lipalangoang tsa metsi [1].

2. 55 ° ho tiisa phala taper khoele CNC ts'ebetso ea machining

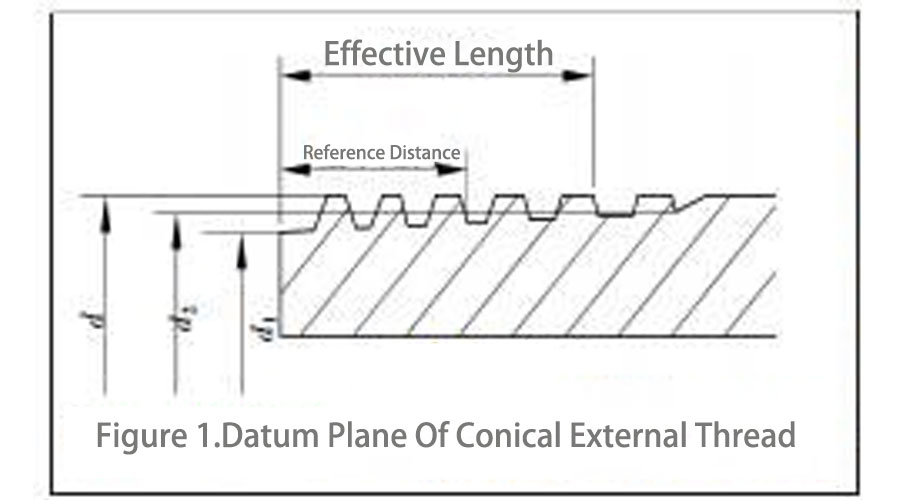

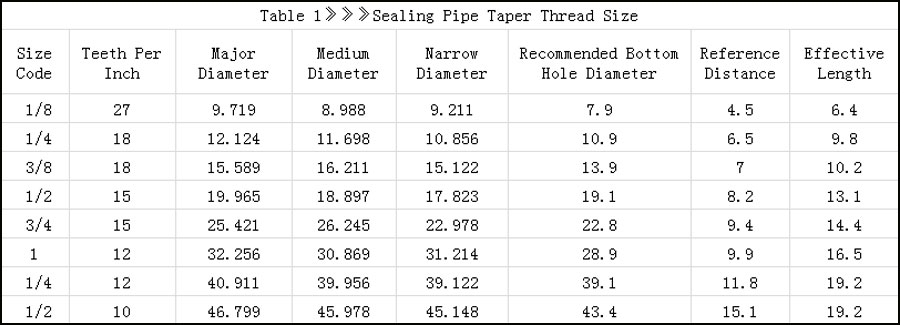

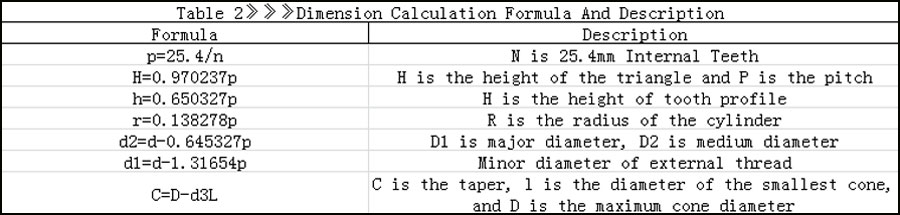

Khoele ea taper ea pipe e arotsoe haholo ka mefuta e 'meli: cone le cylinder, athe khoele ea taper ea pipe e ka ntle ha e na cylinder. Ka ho qapa karo-karolelano ea profil ea taper ea phala ea phala ho 1:16, sebaka se pakeng tsa bokaholimo ba setsi le pheletso ea phala le bolelele bo sebetsang bo tlameha ho lumellana le litekanyetso tse lumellanang. Ho itšetlehile ka tlhahlobo e kopantsoeng ea Setšoantšo sa 1, Letlapa la 1 le Letlapa la 2, ho ea ka lintlha tse tafoleng le mekhoa e amanang le eona, boholo ba khoele ts'ebetsong ea tsamaiso bo ka baloa.

3. Boikemisetso ba litekanyetso tsa taelo bakeng sa ho fetola khoele

3.1 Ka holimo bophara ba khoele

Nakong ea ho khaola khoele, bophara bo ka holimo ba khoele ea ho qetela e entsoeng ka mochine e atolosoa ka polasetiki ka lebaka la extrusion ea sesebelisoa, e tla ba le tšusumetso e kholo ho kopano ea khoele le tšebeliso e tloaelehileng. Basebeletsi ba sebetsang ba tlameha ho nahana ka taba ena pele nakong ea ts'ebetso. . 'Me pele ho khaola khoele, ts'ebetsong ea machining ea cylindrical, lisebelisoa tse ling li lokela ho tlosoa, cylinder e ka ntle e khaotsoe e nyenyane,' me silindara e ka hare e khaoloa e kholoanyane, 'me ho khaola hangata ho laoloa ka hare ho 0.2 ~ 0.3 mm.

3.2 Bophahamo ba profil ea khoele

Bophahamo ba profil ea leino e ke ke ea ba tlase ho 0.6495 p, 'me botebo ba leino ka bophara ba tataiso bo ka beoa hoo e ka bang 1.3 p.

3.3 Botebo bo nang le lera la sehiloeng

Ho na le mekhoa e 'meli ea ho sebetsana le khoele mothating ona. E 'ngoe ke ho sebelisa lisebelisoa tsa tšepe tsa lebelo le phahameng bakeng sa ho sebetsa ka lebelo le tlaase; e 'ngoe ke ho kenya ts'ebetsong ts'ebetso ea lebelo le phahameng ka lisebelisoa tsa carbide le tse koahetsoeng. Mokhoa oa ho hlophisa o tlameha ho ipapisa le thepa ea sesebelisoa. Beha lebelo la ho potoloha [2-3]. 'Me mochini oa CNC hangata o sebetsa ka lebelo le holimo. Nakong ea ts'ebetso ea machining, boleng ba sehiloeng sa pele ke hoo e ka bang 0.5 p, ebe ka makhetlo a 0.7 ho fokotseha ho fetileng. Botebo ba sehiloeng se le seng bo lokela ho ba tlase ho 1, 'me sekhahla se fokolang sa sehiloeng se le seng ha sea lokela ho ba tlase ho 0.1.

3.4 Litekanyo tsa axial tse qalang le tse qetellang

Ha setsebi se kenya khoele holim'a lathe ea CNC, ka lebaka la litšobotsi tse itseng tsa mochine oa servo motor, ts'ebetsong ea ho lokisa khoele, sesebelisoa se lokela ho fihla lebelo le boletsoeng la phepelo ho tloha sebakeng sa pele sa ho emisa, kapa ho theoha ka ho toba ho tloha ho se boletsoeng. lebelo la fepa ho Zero, ho hlokahala hore ho be le ts'ebetso ea phetoho tsamaisong ea ho khanna, 'me ho na le ts'ebetso ea ho potlakisa ts'ebetsong ea ho qala, le ts'ebetso ea ho fokotsa lebelo nakong ea ho emisa. Ts'ebetsong ena, molumo ha oa nepahala. Ka hona, ha o fetola khoele, karolo e ts'oanang ea ho potlakisa ho potlakisa le karolo ea ho khutlisa ea deceleration e lokela ho beoa lipheletsong ka bobeli, 'me boleng ba lipheletsong ka bobeli bo lokela ho khethoa ka mokhoa o utloahalang, ho seng joalo sesebelisoa se tla khaola ha se potlakisa kapa se theoha, se tla etsa hore mochini o theohe. etsahala. Senya le ho hlahisa lihlahisoa tsa maemo a tlase. Ho na le kamano e kholo pakeng tsa litekanyetso tsa ho potlakisa le ho fokotseha ha likarolo le litšoaneleho tse matla, molumo oa khoele le ho nepahala ha mochine oa mochine oa ho khanna. Ka hona, litsebi li lokela ho beha boleng ba mekhahlelo e 'meli ka nepo ho latela litšobotsi tsa mochini oa sistimi ea servo drive. Ka kakaretso, karolo e qalang ea ho potlakisa e kholo ho feta makhetlo a 2 ho etella pele; karolo ea deceleration retreat e pakeng tsa 1 le 1.5 linako tse etellang pele [4]. Ho phaella moo, ts'ebetsong ea ho sebelisa potoloho e entsoeng ka makotikoting, ho lokela ho hlokomeloa hore ho kopanngoa ha ntlha ea ho qala ho kholo ho feta bophara bo tloaelehileng ba khoele, e le ho thibela mengoallo holim'a mochini o entsoeng ka mochine ha sesebelisoa se khutlisetsoa morao [5] .4. Thuto-pale

4.1 Tlhahlobo ea ts'ebetso

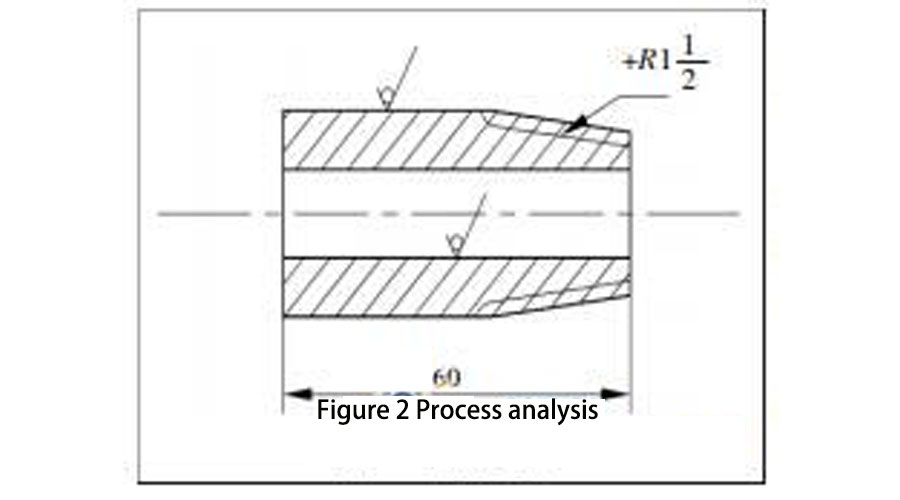

E ka bonoa ho Setšoantšo sa 2 hore bophara ba ka ntle le lesoba le ka hare la phaephe ha e so sebetsoe le ho sebetsoa. Tšimoloho ea phala khoune workpiece ho hokahanya tsamaiso e ka ho toba etselitsoe mateanong a mateano a ka ho le letona qetellong holim'a phala khoune khoele le mola bohareng. Ebe u sebelisa "centering chuck" ho tiisa ntlha e ka ho le letšehali ea thepa ea phaephe, 'me u behe bolelele ba ho atolosa hoo e ka bang 60 mm. Ntlha ea pele, setsebi se ka sebelisa mokhoa oa ho itšeha teko ho etsa lisebelisoa tsa lisebelisoa, ebe se sebelisa sesebelisoa sa ho fetola ka ntle sa 90 ° ho kenya mochine oa bophara bo boholo ba khoele ka mor'a ho qeta [6]; ea bobeli, pele o sebelisa sesebelisoa sa ho fetola khoele ea 55 ° ho sebetsana le khoele ea phala ea phala, pele Phapang ea radius pakeng tsa sebaka sa ho qala le ntlha ea ho qetela ea bophara bo bonyenyane ba phala e baloa, 'me palo ea meno e laoloa pakeng tsa 3 le 4 nakong ea ts'ebetso; qetellong, karolo e khaola ka ho toba ka sesebelisoa sa ho itšeha sa selikalikoe se ka ntle, 'me bolelele bo laoloa ho 60 ho 65 mm.

E ka bonoa ho Setšoantšo sa 2 hore bophara ba ka ntle le lesoba le ka hare la phaephe ha e so sebetsoe le ho sebetsoa. Tšimoloho ea phala khoune workpiece ho hokahanya tsamaiso e ka ho toba etselitsoe mateanong a mateano a ka ho le letona qetellong holim'a phala khoune khoele le mola bohareng. Ebe u sebelisa "centering chuck" ho tiisa ntlha e ka ho le letšehali ea thepa ea phaephe, 'me u behe bolelele ba ho atolosa hoo e ka bang 60 mm. Ntlha ea pele, setsebi se ka sebelisa mokhoa oa ho itšeha teko ho etsa lisebelisoa tsa lisebelisoa, ebe se sebelisa sesebelisoa sa ho fetola ka ntle sa 90 ° ho kenya mochine oa bophara bo boholo ba khoele ka mor'a ho qeta [6]; ea bobeli, pele o sebelisa sesebelisoa sa ho fetola khoele ea 55 ° ho sebetsana le khoele ea phala ea phala, pele Phapang ea radius pakeng tsa sebaka sa ho qala le ntlha ea ho qetela ea bophara bo bonyenyane ba phala e baloa, 'me palo ea meno e laoloa pakeng tsa 3 le 4 nakong ea ts'ebetso; qetellong, karolo e khaola ka ho toba ka sesebelisoa sa ho itšeha sa selikalikoe se ka ntle, 'me bolelele bo laoloa ho 60 ho 65 mm.

4.2 CNC machining lenaneo bakeng sa ho tiisa phala taper khoele

Lenaneo la machining la CNC la ho tiisa khoele ea taper ea pipe ke ka tsela e latelang:

- O0001;

- G40 G99 T0101 M03 S600;

- G00 X55 Z5;

- G71 U1.5 R1;

- G71 P10 Q20 U0.3 W0.05 F0.15;

- N10 G00 X47;

- G01 Z0 F0.1;

- X48.5 Z-23;

- N20 X55 F0.5;

- G70 P10 Q20;

- G00 X100 Z100;

- T0202 M03 S200;

- G00 X55 Z8;

- G92 X46 Z-25 R-0.75 F2.309;

- x45.5;

- X45.;

- x44.7;

- x44.4;

- x44.2;

- x44.1;

- x44.05;

- G00 X100 Z100;

- T0303 M03 S400;

- G00 X55Z 5;

- Z-64;

- G01 X29 F0.1;

- X55 F0.3;

- G00 X100 Z100;

- M05;

- M30;

5.Conclusion

Ka bokhutšoanyane, mochine o sebetsang oa CNC le tsamaiso ea khoele ea khoele ea phala e ke ke ea ntlafatsa feela ho nepahala ha khoele, empa hape e ntlafatsa haholo ts'ebetso ea lathe. Ka hona, ts'ebetso ea ho laola palo ea khoele ea phala ea pipe e ka ntlafatsa haholo boleng ba khokahanyo ea phala e tiisitsoeng. Ho feta moo, basebetsi ba tsamaiso ba lokela ho sebelisa theknoloji e sebetsang hantle haholo bakeng sa ts'ebetso ea taolo ea lipalo, e le ho khothaletsa nts'etsopele e tsoelang pele ea thekenoloji ea taolo ea lipalo.

Kopanya le sengoloa sena: CNC Machining Theknoloji ea Tiisitsoe Pipe Taper Thread

Polelo e Hatisitsoeng: Haeba ho se na litaelo tse ikhethang, lingoloa tsohle tse fumanehang sebakeng sena sa marang-rang ke tsa mantlha. Ka kopo bonts'a mohloli oa khatiso: https: //www.cncmachiningptj.com/ li -ththanks!

PTJ® e fana ka mefuta e felletseng ea Custom Precision cnc machining china ISO 9001: 2015 & JOALOKAHA-9100 pakiloeng. 3, 4 le 5-axis ka potlako e nepahetseng litšebeletso tsa machining tsa CNC ho kenyelletsa le ho sila, ho fetohela ho litlhaloso tsa bareki, Ho khona likarolo tsa tšepe le polasetiki tse nang le mamello ea +/- 0.005 mm.shoa ho lahla,lesela la tšepe 'me stampHo fana ka lipapatso, tlhahiso e felletseng, tšehetso ea tekheniki le tlhahlobo e felletseng likoloi, aerospace, hlobo le sesebelisoa, mabone a lebisitsoeng,ya kalafi, baesekele, le moreki elektronike liindasteri. Tsamaiso ea nako, re bolelle hanyane mabapi le bajete ea projeke ea hau le nako e lebelletsoeng ea ho tlisa Re tla rera leano la hau ho fana ka lits'ebeletso tse bolokang litšenyehelo ho u thusa ho fihlela sepheo sa hau, Rea u amohela sales@pintejin.com ) ka kotloloho bakeng sa projeke ea hau e ncha.

PTJ® e fana ka mefuta e felletseng ea Custom Precision cnc machining china ISO 9001: 2015 & JOALOKAHA-9100 pakiloeng. 3, 4 le 5-axis ka potlako e nepahetseng litšebeletso tsa machining tsa CNC ho kenyelletsa le ho sila, ho fetohela ho litlhaloso tsa bareki, Ho khona likarolo tsa tšepe le polasetiki tse nang le mamello ea +/- 0.005 mm.shoa ho lahla,lesela la tšepe 'me stampHo fana ka lipapatso, tlhahiso e felletseng, tšehetso ea tekheniki le tlhahlobo e felletseng likoloi, aerospace, hlobo le sesebelisoa, mabone a lebisitsoeng,ya kalafi, baesekele, le moreki elektronike liindasteri. Tsamaiso ea nako, re bolelle hanyane mabapi le bajete ea projeke ea hau le nako e lebelletsoeng ea ho tlisa Re tla rera leano la hau ho fana ka lits'ebeletso tse bolokang litšenyehelo ho u thusa ho fihlela sepheo sa hau, Rea u amohela sales@pintejin.com ) ka kotloloho bakeng sa projeke ea hau e ncha.

- 5 selekane Machining

- Cnc siloa

- Cnc fetola

- Mechini ea Machining

- Ts'ebetso ea Machining

- Phekolo ea bokaholimo

- Metal Machining

- Machining ea polasetiki

- Phofo Metallurgy hlobo

- Ho Casting

- Likarolo tsa Gallery

- Likarolo tsa Auto Metal

- Likarolo tsa mechine

- Sesebelisoa sa mocheso oa LED

- Likarolo tsa Kaho

- Likarolo tsa mobile

- Likarolo tsa Bongaka

- Likarolo tsa Elektroniki

- Machining e etselitsoeng

- Likarolo Tsa Baesekele

- Aluminium Machining

- Thaethaniamo Machining

- Lisebelisoa tsa Stainless Steel

- Koporo Machining

- Koporo Machining

- Super motsoako Machining

- Peek Machining

- Machining a UHMW

- Tlanya Machining

- Machining a PA6

- PPS Machining

- Mochini oa Teflon

- Inconel Machining

- Sesebelisoa sa Sesebelisoa sa Steel

- Boitsebiso bo Eketsehileng