Sebetsang hantle Machining Of thaethaniamo motsoako lifofane likarolo

Sebetsang hantle Machining Of thaethaniamo motsoako lifofane likarolo

|

Motsoako oa thaethaniamo o na le melemo ea ho hanyetsa sekhahla se tlase le ts'enyeho, mme o sebelisoa haholo ho aheng litopo tsa lifofane, empa o tloaetse ho fetoha deformation nakong ea ts'ebetso ea cnc, mme ho nepahala ha machining ho thata ho netefatsa. Ka hona, ho hlokahala hore ho sebelisoe theknoloji e tsoetseng pele ea sejoale-joale le meralo ea motheo e phethahetseng ho theha mekhoa e metle ea ho sebetsa, 'me qetellong e ntlafatse ts'ebetso le boleng ba machining ka botlalo CNC lisebelisoa thepa. Tlhahlobo e tebileng e kopantsoe le titanium motsoako motsoako mekhoa e ikemiselitse ho ntlafatsa ts'ebetso ea machining ea likarolo tse amanang |

E le mofuta oa likarolo tse phahameng tsa matla, likarolo tsa motsoako oa titanium li na le boleng bo phahameng haholo ba ts'ebeliso ho likarolo tsa lifofane tšimo. Mekhoa ea moetlo oa mochini oa machining ha e sa hlokahala bakeng sa litlhoko tsa tlhahiso ea meaho ea sejoale-joale ea lifofane. Ka hona, ts'ebeliso ea likarolo tsa motsoako oa titanium e ka fihlela litlhoko tsa nts'etsopele ea lifofane ho isa tekanyong e kholo. Likarolo tsa motsoako oa titanium li sebelisitsoe haholo ho aheng lifofane. Mohlala, li-screws le linate li ka sebelisoa ho lokisa liforeimi tse kholo tsa fuselage, le likarolo tsa bohlokoa joalo ka li-blade tsa enjene le ho kotama Lisebelisoa e ka etsoa ka thepa ea thaethaniamo motsoako.

Masimo a kopo le menyetla ea likarolo thaethaniamo motsoako

1.1 thaethaniamo motsoako likarolo tšimo kopo

Nka mohlala oa sefofane sa baeti sa B777. Li-castings tsa motsoako oa titanium li sebelisoa ha ho etsoa foreimi e kenyang lifofane. Ho ka bonoa hore ha ho etsoa lifofane tsa lehae, theknoloji ea ts'ebeliso ea likarolo tsa motsoako oa titanium e se e holile. Ntle le moo, likarolo tsa motsoako oa titanium le tsona li bohlokoa haholo ntlafatsong ea indasteri ea lifofane. Mohlala, k'hamphani ea European Doncasters e sebelisa theknoloji ea centrifugal casting ho kenya motsoako oa titanium ho brake torque.

1.2 melemo ea ts'ebeliso ea likarolo tsa motsoako oa titanium

Likarolo tsa motsoako oa titanium li na le melemo e latelang ea mahlale:

- Ntlha ea pele, ha ho hlokahale hore ho sebelisoe hlobo nakong ea tšebetso;

- Taba ea bobeli, ha ho na tlhoko ea ho tsetela matla le lichelete tse ngata qalong ea boitokisetso;

- Ntlha ea boraro, e ka ntlafatsa katleho ea tšebeliso ea thepa. Likarolo tsa motsoako oa titanium ha li ntlafatse ts'ebetso ea polokeho ea likarolo tsa sebopeho sa lifofane, empa hape li fokotsa palo ea likarolo tse hokahaneng, ho boloka ka nepo nako ea kopano, le ho fihlela katleho ea nts'etsopele ea mekhahlelo e 'meli le boleng.

Likarolo tsa likarolo tsa motsoako oa lifofane tsa titanium

2.1 ha ho bonolo ho holofala

Sesebelisoa sa motsoako oa titanium se na le matla a phahameng le matla a futhumatsang, 'me se na le letsoalo le tlase. Ha e bapisoa le lisebelisoa tsa tšepe, ke 60% feela ea letsoalo la tšepe. Sena se etsa lisebelisoa tsa motsoako oa titanium ntle le mathata a ho fetoha esita le maemong a phahameng a 300 ° C ho isa ho 500 ° C. Sebopeho sa motsoako oa titanium oa mofuta o itseng oa enjene ea lifofane se sebetsoa ke motsoako oa TC4 oa titanium betloas. Boima ke 19.987kg, bophara ke 600mm, bolelele ke 2800mm, empa botenya ba lerako ke 1.50mm feela.

2.2 mocheso o tlase oa ho hanyetsa

Motsoako oa titanium o na le mocheso o tlase oa mocheso, ke hore, o ntse o ka boloka thepa ea ona ea mochini tlasa maemo a mocheso o tlase kapa o tlase haholo. Ke sesebelisoa se nang le mocheso o matla o tlase oa mocheso. Ho latela liteko tse amanang, hoa tsebahala hore motsoako oa titanium o ho -196 ° C. Ka tlase, matla a tensile σb ke 1207Pa.

2.3 e matla ts'enyeho hanyetsa

Likarolo tsa motsoako oa titanium li ka sebelisoa haholo lebaleng la lifofane, lebaka la bohlokoa haholo ke hore e na le ts'ireletso e matla ea kutu. Ha sefofane se fofa sebakeng se phahameng haholo, lintho tse moeeng li tla ba le phello e itseng e senyehang holim'a sefofane. Likarolo tsa motsoako oa titanium li ka sebetsana ka katleho le bothata bona mme tsa netefatsa polokeho ea sefofane.

2.4 Ka thepa ea lik'hemik'hale

Li-alloys tsa titanium li ka sebetsana le likarolo tse fapaneng tsa tšepe. Ka thuso ea liphetoho tsa lik'hemik'hale, likarolo tsa mochini oa lits'epe tse kopantsoeng tsa titanium li ka holisoa. Mohlala, tikolohong e phahameng ea mocheso o kaholimo ho 600 ° C, lits'epe tse kopantsoeng tsa titanium li ka sebetsana le oksijene ho theha mokelikeli o lekanang oa oxide.

2.5 tlaase conductivity mogote

Ts'ebeliso ea likarolo tsa motsoako oa titanium lifofaneng e ka fokotsa menyetla ea ho hloleha ha likarolo tsa sefofane, mme ea qoba ho khanna mocheso o feteletseng oa likarolo tsa sefofane tse amang ts'ebeliso e tloaelehileng ea likarolo tse ling.

2.6 Modulus e nyane ea elasticity

Ha o ntse o sebelisa likarolo tsa motsoako oa titanium, o se ke oa li etsa likarolo tse nyane. Lebaka ke hore modulus ea elastic ea titanium alloy e nyane mme ho bonolo ho e holofala. Ntle le moo, ho mochini oa thaethaniamo ts'ebetso, ka lebaka la mokokotlo o moholo oa motsoako oa titanium, ho bonolo ho roala sesebelisoa.

Mehato ea Machining le ea Ts'ebeliso ea likarolo tsa motsoako oa lifofane tsa titanium

Indasteri ea lifofane ea China e nka bohlokoa ba ts'ebeliso ea lisebelisoa tse tala, mme sepheo sa R&D se ho nts'etsopele ea ts'ebetso le ts'ebeliso e le ho ntlafatsa ts'ebetso ea lifofane.

3.1 Atolosa tšimo ea ts'ebeliso ea li-castings tsa titanium alloy

Bapisoa le tse ling likarolo tsa titanium, mokhoa oa ho lahla matsete o na le menyetla ea oona e ikhethang:

- Boholo ba ho lahla bo nepahetse, bokaholimo bo batla bo le boreleli, 'me ho ba thata ho tlase;

- E ka akhela castings e rarahaneng e bōpehileng joaloka;

- Ha e ntse e ntlafatsa sekhahla sa ts'ebeliso ea lisebelisoa tse tala tsa tšepe, e ka ntlafatsa ntlafatso ea lihlahisoa le ho ikamahanya le maemo.

Leha ho le joalo, ts'ebetsong ea ts'ebeliso, matla a lits'epe tsa thaethaniamo a ke ke a fihlela ka botlalo litlhoko tsa kaho ea lifofane. Ka hona, ho hatisoa ho lokela ho beoa ntlafatsong ea matla a tšepe ea lits'epe tse kopantsoeng tsa titanium nakong ea lipatlisiso le nts'etsopele. Lebelo la nts'etsopele ea theknoloji ea ho lahla ka mokhoa o nepahetseng ea thaethaniamo naheng ea heso e ntse e eketseha khafetsa lilemong tsa morao tjena. Motheong ona, diagonal overrunning clutch e sebelisitsoe haholo lebaleng la lifofane. Ka lebaka la litlhoko tse phahameng tsa lifofane bakeng sa likarolo tsa titanium alloy, sekhahla sa sebopeho sa likarolo tsa naha ea heso ea titanium alloy se batla se le tlase. Ka hona, mahlale le mahlale a morao-rao a tlameha ho sebelisoa ho ntlafatsa boemo ba ho betsa, ho fokotsa litšenyehelo tsa tlhahiso ea lihlahisoa le mekoloko ea tlhahiso, le ho fihlela sepheo sa tlhahiso ea bongata. .

3.2 Fokotsa litšenyehelo tsa nts'etsopele

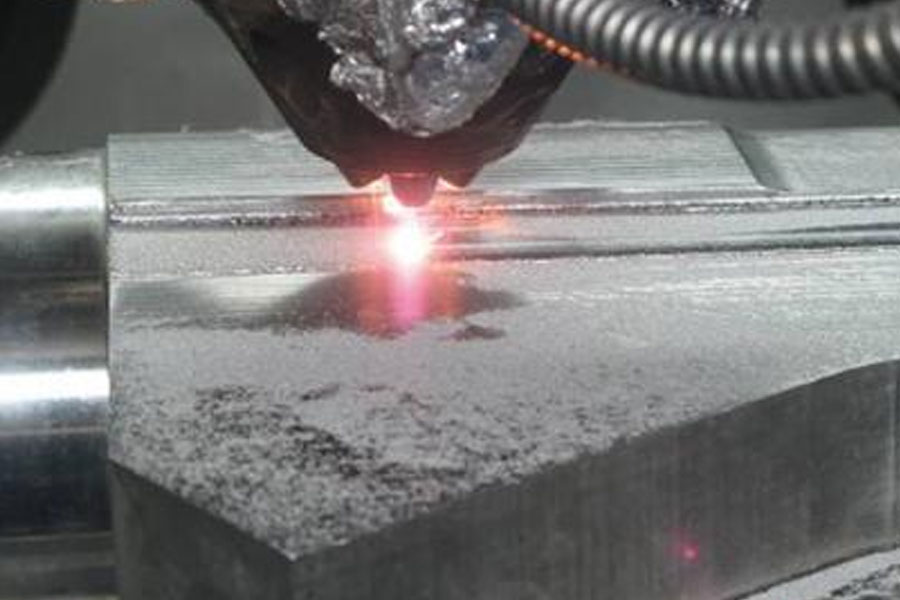

Motheong oa ho roala tham mong bang laser e nang le matla a maholo le prototyping e potlakileng, theknoloji ea theknoloji ea thaethaniamo ea thaethaniamo e sebelisitsoe haholo. Mahlale ana a sebelisa toloki e nang le matla a mangata ho qhibilihisa phofo ea thaethaniamo le ho e tiisa holima substrate ka sebopeho sa marotholi a manyane, ebe o ts'epa theknoloji ea taolo ea likhomphutha ho etsa hore hlooho ea laser e sisinyehe khafetsa, ka ho etsa joalo e bokella lera ka lera, mme qetellong fumana mofuta o hlokahalang oa likarolo tsa titanium.

Hajoale, ts'ebetso ea kakaretso ea sebopeho sa motsoako oa titanium e ntlafalitsoe haholo, mme boima ba karolo ka boeona bo fokotsoe haholo, bo khahliloeng ke lefapha la lifofane.Mmoho le boemo ba nnete, litjeo tsa Nb, Mo le likarolo tsa V ho lits'epe tsa tšepe tsa titanium li theko e tlase, e lebisang ho litheko tse phahameng tsa thepa e tala.

Ka hona, lits'epe tsa tšepe tsa lifofane tse nang le matsete a theko e tlase li hohetse tlhokomelo e kholo. Hajoale, bafuputsi ba fumane hore likarolo tsa Fe li ka sebelisoa ho nkela likarolo tsa Nb, Mo le V tse theko e phahameng, tse ke keng tsa netefatsa ts'ebetso ea lisebelisoa feela, empa hape li fokotsa litšenyehelo tsa ho kenya lihlahisoa tsa lihlahisoa tsa titanium.

3.3 Kabo le mokhoa oa ts'ireletso ea bokaholimo

Ha ho hlahlojoa lera la bokaholimo ba BT3-1 le OT4-1, ho ka phetheloa hore kabo ea haedrojene mokatong o kaholimo e batla e le thata, 'me litaba tsa haedrojene li tla nyoloha hanyane ka hanyane,' me ha e fihla boleng bo holimo, e e tla fokotseha ka nepo. Hajoale, laser ea mahlakore a mararo e etsa theknoloji le likarolo tsa titanium alloy li kopantsoe ka nepo, 'me boholo ba titanium alloy main ho jara likarolo tsa lifofane li entsoe.

3.4 Ntlafatsa tšepe tshebediso Ntlha ea chesang betloa ha shoa

Mokhoa o atlehang ka ho fetesisa oa ho eketsa ts'ebeliso ea ts'ebeliso ea tšepe ke ho sebelisa futhumatsang e nang le oxidation e tlase le e se nang oxidation. Bakeng sa lits'epe tse kopantsoeng tsa titanium, ho futhumatsa sekheo ka moea o omileng ho ka rarolla bothata bona hantle. Ho latela lipatlisiso tse amanang, ha ho futhumatsoa seboping sa motlakase, mocheso o lokela ho laoloa ho 950 ℃ ~ 980 ℃. Ntle le moo, ka ho etsa liteko ho BT20 le OT4-1 (TC1), ho futhumatsa disampole tsohle le ho shoa ho betloa ka mokhoa o ts'oanang, ho ka fumanoa hore bokaholimo ba boea bo nang le mocheso oa pele o nang le oxidized bo sa bonahaleng bo bonts'a phello e boreleli, e lebisang ho sephetho sa hore mokato oa oxide le mmuso oa ho tlatsa khase li na le tšusumetso ea bohlokoa ho thepa ea mochini.

fihlela qeto e

Maemong a nts'etsopele e tsoelang pele ea mahlale le mahlale a morao-rao, likhoebo tse ngata li phethetse phetoho ea tsona, mme indasteri ea naha ea ka ea aluminium le eona e fihletse litholoana tse ntle. Ts'ebetsong ea kholo e potlakileng ea moruo, indasteri ea motsoako oa titanium e ntse e tsoela pele ho nts'etsapele matla a nchafatsoang, e nolofalletsa likarolo tsa motsoako oa titanium hore li sebelisoe hantle masimong a mang, ho rala motheo o tiileng bakeng sa nts'etsopele ea paballo ea matla le phokotso ea mochini.

Kopanya le sengoloa sena: Sebetsang hantle Machining Of thaethaniamo motsoako lifofane likarolo

Polelo e Hatisitsoeng: Haeba ho se na litaelo tse ikhethang, lingoloa tsohle tse fumanehang sebakeng sena sa marang-rang ke tsa mantlha. Ka kopo bonts'a mohloli oa khatiso: https: //www.cncmachiningptj.com/ li -ththanks!

PTJ® e fana ka mefuta e felletseng ea Custom Precision cnc machining china ISO 9001: 2015 & JOALOKAHA-9100 pakiloeng. 3, 4 le 5-axis ka potlako e nepahetseng litšebeletso tsa machining tsa CNC ho kenyelletsa le ho sila, ho fetohela ho litlhaloso tsa bareki, Ho khona likarolo tsa tšepe le polasetiki tse nang le mamello ea +/- 0.005 mm.shoa ho lahla,lesela la tšepe 'me stampHo fana ka lipapatso, tlhahiso e felletseng, tšehetso ea tekheniki le tlhahlobo e felletseng likoloi, aerospace, hlobo le sesebelisoa, mabone a lebisitsoeng,ya kalafi, baesekele, le moreki elektronike liindasteri. Tsamaiso ea nako, re bolelle hanyane mabapi le bajete ea projeke ea hau le nako e lebelletsoeng ea ho tlisa Re tla rera leano la hau ho fana ka lits'ebeletso tse bolokang litšenyehelo ho u thusa ho fihlela sepheo sa hau, Rea u amohela sales@pintejin.com ) ka kotloloho bakeng sa projeke ea hau e ncha.

PTJ® e fana ka mefuta e felletseng ea Custom Precision cnc machining china ISO 9001: 2015 & JOALOKAHA-9100 pakiloeng. 3, 4 le 5-axis ka potlako e nepahetseng litšebeletso tsa machining tsa CNC ho kenyelletsa le ho sila, ho fetohela ho litlhaloso tsa bareki, Ho khona likarolo tsa tšepe le polasetiki tse nang le mamello ea +/- 0.005 mm.shoa ho lahla,lesela la tšepe 'me stampHo fana ka lipapatso, tlhahiso e felletseng, tšehetso ea tekheniki le tlhahlobo e felletseng likoloi, aerospace, hlobo le sesebelisoa, mabone a lebisitsoeng,ya kalafi, baesekele, le moreki elektronike liindasteri. Tsamaiso ea nako, re bolelle hanyane mabapi le bajete ea projeke ea hau le nako e lebelletsoeng ea ho tlisa Re tla rera leano la hau ho fana ka lits'ebeletso tse bolokang litšenyehelo ho u thusa ho fihlela sepheo sa hau, Rea u amohela sales@pintejin.com ) ka kotloloho bakeng sa projeke ea hau e ncha.

- 5 selekane Machining

- Cnc siloa

- Cnc fetola

- Mechini ea Machining

- Ts'ebetso ea Machining

- Phekolo ea bokaholimo

- Metal Machining

- Machining ea polasetiki

- Phofo Metallurgy hlobo

- Ho Casting

- Likarolo tsa Gallery

- Likarolo tsa Auto Metal

- Likarolo tsa mechine

- Sesebelisoa sa mocheso oa LED

- Likarolo tsa Kaho

- Likarolo tsa mobile

- Likarolo tsa Bongaka

- Likarolo tsa Elektroniki

- Machining e etselitsoeng

- Likarolo Tsa Baesekele

- Aluminium Machining

- Thaethaniamo Machining

- Lisebelisoa tsa Stainless Steel

- Koporo Machining

- Koporo Machining

- Super motsoako Machining

- Peek Machining

- Machining a UHMW

- Tlanya Machining

- Machining a PA6

- PPS Machining

- Mochini oa Teflon

- Inconel Machining

- Sesebelisoa sa Sesebelisoa sa Steel

- Boitsebiso bo Eketsehileng