Sebopeho se Ratoang sa Lifofane Aluminium Alloy 7A09

T73 Tlhaloso ea Botsofali ba Maiketsetso bakeng sa Lipoleiti, Li-Extrusions le Forgings

Har'a lisebelisoa tsa aluminium bakeng sa likoloi tsa sefofane naheng ea China, 7A09 alloy ke e 'ngoe ea li-alloys tse ratoang haholo bakeng sa likarolo tse kholo tsa meralo. Lihlahisoa tse feliloeng tse fumanehang li kenyelletsa lipoleiti, likhoele, mekoallo, li-profiles, li-tubes tse teteaneng, betloas, joalo-joalo Sebopeho sa lik'hemik'hale se na le kahlolo e molemo ho feta ea 7A04 alloy, kahoo e na le ts'ebetso e phahameng ka ho fetisisa 'me e fetoha e' ngoe ea lisebelisoa tse ka sehloohong tsa moqapi. Sebopeho sa eona sa lik'hemik'hale (boima%): 0.5Si, 0.5Fe, (1.2-2.0) Cu, 0.15 Mn, (2.0-3.0) Mg, (0.16-0.30) Cr, (5.1-6.1) Zn, 0.10Ti, litšila tse ling ka bonngoe ke 0.05, kakaretso ea 0.10, 'me tse ling kaofela ke Al.

7A09 alloy e na le thepa e ntle ea ho bopa libakeng tsa kalafo ea annealed le tharollo. Ka mor'a botsofali ba maiketsetso, thepa ea ho theha e fokotsehile, 'me ho thatafala ha fracture hoa khotsofatsa sebakeng sa T6; le hoja matla a tlas'a boemo ba T73 overaging a le tlase ho feta sebakeng sa T6, E na le khanyetso e ntle ea khatello ea maikutlo ea ho senya 'me e na le boima bo phahameng. Lisebelisoa tsa T76 li na le khanyetso e phahameng ea spalling le corrosion. T74 e na le matla a phahameng le ho hanyetsa khatello ea maikutlo ho senya ho phunyeha ka nako e le 'ngoe.

The tensile strength Rm of 7A09 alloy e phahame ho feta ea 2A12 le 2A14 aluminium alloys, 'me khatello ea eona ea khatello ea khatello ea maikutlo e boetse e phahame ho feta ea bona. Ka hona, tšebeliso ea eona ho etsa likarolo tsa lifofane ha e na phello e kholo ea ho fokotsa boima ba 'mele feela, empa hape e na le tšireletso e phahameng. Ka hona, matla a eona a mokhathala ha a e-s'o eketsehe ka ho loketseng. Ka hona, hoa hlokahala ho nahana ka taba ena ka botebo ha ho etsoa lisebelisoa tse nang le mokhathala o mongata haholo. Ha mocheso o phahama, matla a 7A09 alloy a fokotseha ka potlako, kahoo mocheso oa eona o sebetsang ha oa lokela ho feta 125 ° C.

Tlhaloso e sa fellang ea annealing ea 7A09 alloy: 290℃——320℃, 2h——4h, moea o pholileng; tlhaloso e feletseng ea annealing: (390℃——430℃)/(0.5h——1.5h), ka ≤30℃/h Sekhahla sa ho pholisa se ka tlase kapa se lekana le 200℃, ebe se pholile moea ka ntle ho sebōpi.

Mocheso oa phekolo ea tharollo ea motsoako ona ke 460 ℃-475 ℃, empa mocheso oa phekolo oa letlapa le koahetsoeng ke aluminium e lokela ho ba ka tlaase ho moeli o ka tlaase, eseng makhetlo a fetang 2, e le ho thibela likarolo tsa motsoako ho phunyeletsa aluminium- clad layer le ho fokotsa ho hanyetsa ha kutu ea thepa. Sebaka sa ho futhumatsa ke mocheso oa kamore, metsi a futhumetseng kapa mokhoa o mong o loketseng, phetisetso ha ea lokela ho feta 15s. Mocheso oa ho sebetsa oa poleiti ea T6 ke (135℃±5℃)/(8h—16h), le bakeng sa lisebelisoa tse ling, ke (140℃±5℃)/16h. Sheba tafole bakeng sa litlhaloso tsa botsofali tsa maiketsetso tsa lipoleiti tsa T73, lisebelisoa tse extruded le forgings.

Thepa ea ho qhibilihisa ea 7A09 alloy e tšoana le ea lisebelisoa tse ling tse entsoeng ka aluminium. Mocheso o qhibilihang ke 710 ℃-750 ℃, 'me mocheso oa ho lahla ke 710 ℃-735 ℃. Boholo ba ingot bo nyane mme mocheso o tlase oa ho lahla o khethoa. Mocheso o qhibilihang oa alloy ke 477 ℃. ——638°C.

7A09 alloy ke motsoako oa bohlokoa oa sebopeho sa aluminium bakeng sa khatello ea maikutlo. E 'nile ea sebelisoa haholo ha ho etsoa lifofane, lifofane tsa libomo tse mahareng, lifofane tsa lipalangoang le bakoetlisi. E sebelisetsoa ho etsa hore nko e koale Lisebelisoa likarolo, maballo a mapheo a ka pele, maballo, le boema-kepe ba fuselage. Matsoho le litšiea tse tšehetsang foreimi, li-partitions, likhopo, manonyeletso a mantlha, mehatla e bataletseng e kaholimo le e tlase ea lebota, likarolo tsa sistimi ea hydraulic, lithupa tsa piston tsa oli ea hydraulic, li-cylinders tse kahare le kantle le likarolo tse ling tsa bohlokoa.

The fracture toughness (Kc, N/mm2,) ea 7A09-T73 alloy e phahame ho feta ea thepa ea T6, 'me sekhahla sa eona sa ho hōla ha crack se tlase ho feta sa thepa ea T6. Matla a eona a mokhathala a boetse a molemo ho feta a thepa ea T6, 'me conductivity ea eona ea mocheso e boetse e phahame ho feta ea thepa ea T6. Mocheso o khethehileng oa mocheso oa 7A09-T6 alloy ho 50 ° C ke 888J / (kg. ° C), 'me mocheso oa mocheso oa kamore ke 18.5MS / m. Ntle le ts'ebetso ea ho phatloha ha khatello ea maikutlo, khanyetso e akaretsang ea corrosion ea 7A09 alloy e lekana le ea 2A12 alloy. 7A09 alloy e na le maikutlo a ho sithabela ha kutu ho ea ka lehlakoreng la ST, 'me moeli oa khatello ea maikutlo ho LT le L directions o moholo ho feta 300N / mm2, kahoo khatello ea khatello ea khatello ea maikutlo ka litsela tsena tse peli e lekane ho finyella litlhoko tsa tšebeliso. Haeba tlhokahalo e phahame, lisebelisoa tsa T73 li ka sebelisoa. Matla a matla a Rm a thepa sebakeng sena a batla a le tlase ho 10% ho feta a thepa ea T6, empa khatello ea khatello ea khatello ea kelello e senya boleng ba tataiso ea LT e kholo ho feta ea 300N / mm2.

Bakeng sa likarolo tse hlokang ts'ebetso ea matla le khatello ea maikutlo, lisebelisoa tsa mmuso tsa T74 li lokela ho sebelisoa. The stress corrosion cracking monyako oa 7A09-T74 alloy die forgings ke 210N/mm2. Mehato e thibelang ho bola ea 7A09 alloy e kenyeletsa anodic oxidation, phekolo ea lik'hemik'hale e thibelang ho bola le ho penta.

Sebopeho sa motsoako oa 7A09 se na le tharollo e tiileng ea α-Al le likaroloana tsa karolo ea bobeli. Karolo ea bobeli e na le mefuta e meraro: mofuta oa pele ke metsoako ea intermetallic e entsoeng nakong ea alloy solidification, e kang Al7FeCR, Al3Fe, le Mg2Si. Boholo bo batla bo le boholo. E pshatleha ka likotoana ebe e aroloa ka lihlopha. Boholo ke 0.5μm-10μm. Ha e qhibilihe ka tharollo e tiileng ha e futhumetse 'me e fokotsa ho tiea ha thepa. Mofuta oa bobeli ke likaroloana tse nang le chromium tse kang Al2CrMg2, e leng li-ingots tse nang le homogenized 'me E kenngoa ka tharollo e tiileng nakong ea ho futhumatsa pele e sebetsa,' me boholo ba eona ke 0.05μm-0.5μm, e nang le tšitiso e kholo ho ts'ebetso ea recrystallization le kholo ea lijo-thollo tsa thepa; mofuta oa boraro ke mohato oa ho matlafatsa botsofali, e leng phekolo e tiileng ea tharollo. Ho kenyelletsa tharollo e tiileng le ho tsofala ho tsoa ho tharollo e tiileng ke lintlha tsa bohlokoa tse amang thepa ea thepa. Likarolo tse matlafatsang tsa thepa ea mmuso oa T6 haholo-holo sebaka sa GP ≤4nm, likaroloana tse ka sehloohong tse matlafatsang tsa thepa ea T74 ke karolo ea phetoho η'of 5nm-6nm, mohato o matlafatsang oa thepa ea T73 ke mohato oa phetoho η'of 8nm-12nm le 20nm-80nm Η likaroloana.

Sebopeho sa thepa ea 7A09-O e lekana le ea motsoako oa 2A12-O, 'me e na le sebopeho se setle ho 180 ° C-370 ° C; sebopeho sa thepa e ncha e tingoeng e batla e tšoana le ea motsoako oa 2A12. Letlapa le tima ka mocheso oa kamore bakeng sa 4h Ho ntse ho e-na le sebopeho se setle ka hare, le nako ea ho qhoqhoa ho boloka sebopeho: 24h ho 0 ℃, 3d ho -7 ℃, 7d ho -18 ℃.

Mocheso oa forging oa 7A09 alloy ke 320 ° C-440 ° C, 'me mocheso oa ho bula o lokela ho ba ≤400°C. Ho phahama haholo ho tla baka brittleness e chesang, haholo-holo nakong ea forging mahala. 7A09 alloy ha e bonolo ho tjheseletsa, esita le ho tjheseletsa ho hanyetsa ha ho molemo joaloka motsoako oa 2A12. Forgings e ka tima ka metsing a chesang a ≤80 ℃. Motsoako oa 7A09 ka mor'a ho tima le phekolo e sebetsang e na le machinability e ntle.

Kopanya le sengoloa sena: Sebopeho se Ratoang sa Lifofane Aluminium Alloy 7A09

Polelo e Hatisitsoeng: Haeba ho se na litaelo tse ikhethang, lingoloa tsohle tse fumanehang sebakeng sena sa marang-rang ke tsa mantlha. Ka kopo bonts'a mohloli oa khatiso: https: //www.cncmachiningptj.com/ li -ththanks!

3, 4 le 5-axis e nepahetseng CNC lisebelisoa ditshebeletso tsa aluminium machiningberyllium, tšepe ea carbon, magnesium, mochini oa thaethaniamo, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite le lehong. E khona ho etsa likarolo tsa machining ho fihlela ho 98 in. turning dia. le +/-0.001 in. mamello e otlolohileng. Mehato e kenyelletsa ho sila, ho cheka, ho bora, ho ts'oara, ho tlanya, ho theha, ho loha, ho loants'a, ho qhekella, ho reaming le ho khaola laser. Litšebeletso tsa bobeli tse kang ho kopanya, ho sila ho se na setsi, ho phekola mocheso, ho pata le ho cheselletsa. Prototype le tlhahiso e tlase ho isa ho e phahameng e fanoang ka boholo ba li-unit tse 50,000. E loketse matla a mokelikeli, pneumatics, hydraulics le phunyang ditshebediso. E sebeletsa sebaka sa lifofane, lifofane, sesole, bongaka le ts'ireletso. sales@pintejin.com ) ka kotloloho bakeng sa projeke ea hau e ncha.

3, 4 le 5-axis e nepahetseng CNC lisebelisoa ditshebeletso tsa aluminium machiningberyllium, tšepe ea carbon, magnesium, mochini oa thaethaniamo, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite le lehong. E khona ho etsa likarolo tsa machining ho fihlela ho 98 in. turning dia. le +/-0.001 in. mamello e otlolohileng. Mehato e kenyelletsa ho sila, ho cheka, ho bora, ho ts'oara, ho tlanya, ho theha, ho loha, ho loants'a, ho qhekella, ho reaming le ho khaola laser. Litšebeletso tsa bobeli tse kang ho kopanya, ho sila ho se na setsi, ho phekola mocheso, ho pata le ho cheselletsa. Prototype le tlhahiso e tlase ho isa ho e phahameng e fanoang ka boholo ba li-unit tse 50,000. E loketse matla a mokelikeli, pneumatics, hydraulics le phunyang ditshebediso. E sebeletsa sebaka sa lifofane, lifofane, sesole, bongaka le ts'ireletso. sales@pintejin.com ) ka kotloloho bakeng sa projeke ea hau e ncha.

- 5 selekane Machining

- Cnc siloa

- Cnc fetola

- Mechini ea Machining

- Ts'ebetso ea Machining

- Phekolo ea bokaholimo

- Metal Machining

- Machining ea polasetiki

- Phofo Metallurgy hlobo

- Ho Casting

- Likarolo tsa Gallery

- Likarolo tsa Auto Metal

- Likarolo tsa mechine

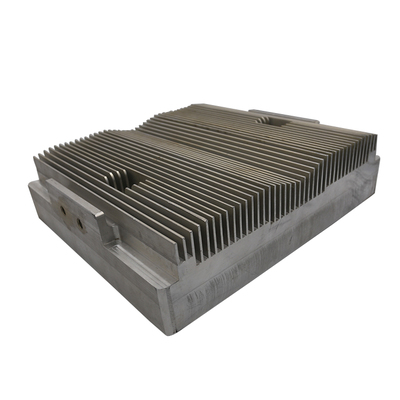

- Sesebelisoa sa mocheso oa LED

- Likarolo tsa Kaho

- Likarolo tsa mobile

- Likarolo tsa Bongaka

- Likarolo tsa Elektroniki

- Machining e etselitsoeng

- Likarolo Tsa Baesekele

- Aluminium Machining

- Thaethaniamo Machining

- Lisebelisoa tsa Stainless Steel

- Koporo Machining

- Koporo Machining

- Super motsoako Machining

- Peek Machining

- Machining a UHMW

- Tlanya Machining

- Machining a PA6

- PPS Machining

- Mochini oa Teflon

- Inconel Machining

- Sesebelisoa sa Sesebelisoa sa Steel

- Boitsebiso bo Eketsehileng