Tlhaloso e khutšoane ea theknoloji ea khatiso ea carbon fiber 3D le ts'ebeliso ea eona indastering ea likarolo

2019-09-14

Tlhaloso e khuts'oane ea Khatiso ea Carbon fiber 3D

| 3D fiber ea khabone e hatisitsoeng ke theknoloji ea bobeli e batloang haholo kamora tšepe. Ka lebaka la litšobotsi tse ikhethileng tsa fiber ea khabone, joalo ka: e bobebe, matla a phahameng, ho khanna ho phahameng ha motlakase, ho hanela ts'enyeho haholo, likarolo tse entsoeng ka mahlale a khatiso a 3D hangata li na le ts'ebetso e phahameng le ts'ebetso e phahameng. |

Theknoloji ea khatiso ea Carbon fiber 3D

▶ Theknoloji ea laser sinteringLitšobotsi tsa lintho tse bonahalang: Nylon e nyane e matlafalitsoeng ea nylon, PEEK, TPU le lisebelisoa tse ling tsa phofo

Likarolo tsa ts'ebetso: Kopanya fiber e khutsufalitsoeng ea khabone le thepa ea nylon ka bongata bo itseng, 'me u hlokomele sebopeho sa bohlokoa sa laser sintering.

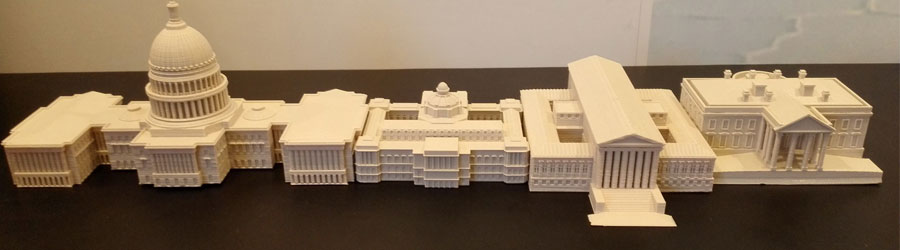

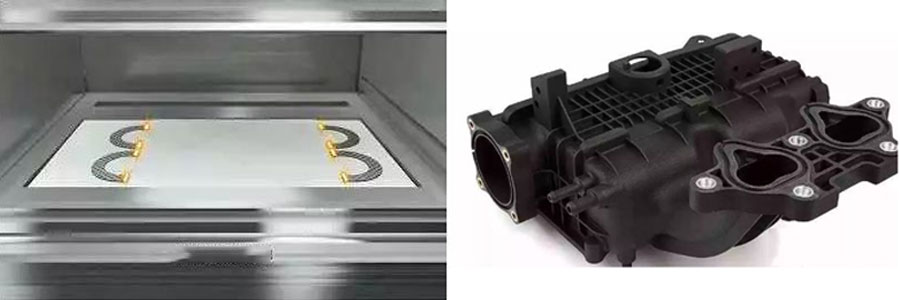

Laser sintered carbon fiber e amohelang mefuta e mengata ea ts'ebetso

▶ Theknoloji ea melting ea jet e ngata

Litšobotsi tsa lintho tse bonahalang: Nylon e nyane e matlafalitsoeng ea nylon, PEEK, TPU le lisebelisoa tse ling tsa phofo

Litšobotsi tsa ts'ebetso: Ka ho futhumatsa ha tube ea lebone, karolo ea sefapano e bokella mocheso o lekaneng ho lemoha ho qhibiliha ho etsa tlasa bohato ba mokelikeli.

MJF theknoloji ea khatiso ea fiber e matlafalitsoeng likarolo

▶ Theknoloji ea FDMLitšobotsi tsa lisebelisoa: fiber e telele e matlafalitsoeng PLA, nylon, PEEK le lisebelisoa tse ling tsa terata

Litšobotsi tsa ts'ebetso: Faeba e telele e tlatsitsoe ka terata e tloaelehileng ke mahlale a FDM ho ntlafatsa phello.

FDM e hatisitsoeng ka fiber fiber e matlafalitseng lepheo la PEEK

Mokhoa oa khatiso oa Carbon fiber

▶ Carbon fiber e tlatsitsoeng e tletse thermoplastic.Li-thermoplastics tse tlatsitsoeng ka nako e khuts'oane tse tlatsitsoeng ka khabone li hatisoa ho printa e tloaelehileng ea FFF (FDM) e nang le thermoplastic (PLA, ABS kapa nylon) e matlafalitsoeng ka likhoele tse nyane tse hahiloeng, ke hore, likhoele tsa khabone. Ka lehlakoreng le leng, tlhahiso e tsoelang pele ea khalase ea khabone ke mochini o ikhethileng oa ho hatisa o behang mekotla e tsoelang pele ea khabone ea fiber ho li-substrates tse tloaelehileng tsa FFF (FDM).

Lipolasetiki tse tlatsitsoeng ka nako e khuts'oane tsa khabone le likhoele tse tsoelang pele li etsoa ka tšebeliso ea fiber ea khabone, empa phapang lipakeng tsa tsona e kholo. Ho utloisisa hore na mokhoa o mong le o mong o sebetsa joang le ts'ebeliso ea ona e nepahetseng ho tla u thusa ho etsa liqeto tse nang le tsebo mabapi le seo u lokelang ho se etsa tlhahiso e tlatselletsang.

3D fiber e hatisitsoeng ea khabone e entsoe ka khalase ea khabone e tlatsitsoeng e nang le thermoplastic

Likhoele tse hahiloeng tsa khabone li matlafatsa thepa ea li-thermoplastics tse tloaelehileng. E lumella lik'hamphani ho hatisa thepa eo hangata e seng matla haholo maemong a phahameng a matla. Lisebelisoa li kopantsoe le thermoplastic mme motsoako o hlahisoang o ntšetsoa ka har'a spool bakeng sa mokhoa oa ho qhibiliha oa likhoele (FFF).

Bakeng sa likarolo tse sebelisang mokhoa oa FFF, thepa ke motsoako oa likhoele tse hahiloeng (hangata likhoele tsa khabone) le li-thermoplastics tse tloaelehileng (joalo ka nylon, ABS kapa polylactic acid). Leha ts'ebetso ea FFF e lula e ts'oana, likhoele tse hahiloeng li eketsa matla le ho satalla ha mofuta ona le ho ntlafatsa botsitso ba sebopeho, qetello ea bokaholimo le ho nepahala.

Mokhoa ona ha se kamehla o se nang liphoso. Likhoele tse ling tse tlotsitsoeng li matlafatsa likhoele ka hore li fetole boemo ba tsona bo phahameng haholo ka likhoele. Sena se ka ama boleng ba mosebetsi hampe, sa fokotsa boleng ba bokaholimo le ho nepahala hoa karolo. Prototypes le likarolo tsa ts'ebeliso li ka etsoa ka fiber ea khabone e khethiloeng hobane e fana ka matla le chebahalo e hlokahalang bakeng sa liteko tsa kahare kapa likarolo tse shebaneng le bareki.

Khatiso ea Carbon fiber 3D e ntlafatsoa ka likhoele tse tsoelang pele

Lisebelisoa tse tsoelang pele tsa carbon fiber.

Molemo o tsoelang pele oa khabone ke monyetla oa 'nete. Ena ke tharollo e bolokang chelete e ngata ho khutlisa likarolo tsa tšepe tsa setso ka likarolo tse hatisitsoeng tsa 3D hobane e fihlela matla a tšoanang ka ho sebelisa karoloana feela ea boima. E ka sebelisoa ho kenya lisebelisoa tsa thermoplastics ho sebelisa theknoloji e tsoelang pele ea tlhahiso ea li-filament (CFF). Mohatisi o sebelisang mokhoa ona o beha likhoele tse matla tse tsoelang pele (mohlala, khalase ea khabone, fiberglass kapa Kevlar) ka nozzle ea bobeli ea khatiso ho FFF e ntšitsoeng ka ntle ho thermoplastic nakong ea khatiso. Ho matlafatsa likhoele ho etsa "mokokotlo" oa karolo e hatisitsoeng, ho hlahisa phello e thata, e matla le e tšoarellang.

Carbon fiber e tsoelang pele ha e eketse matla feela, empa e boetse e fa basebelisi matlafatso a khethang libakeng tseo ho tsona ho tšoarellang ho phahameng ho hlokahalang. Ka lebaka la sebopeho sa FFF sa tšebetso ea mantlha, o ka khetha ho aha motheong oa lera-ka-lera.

Lera ka leng, ho na le mekhoa e 'meli ea ntlafatso: matlafatso a tsepamisitsoeng le matlafatso ea isotropic. Concentric e tlatsa ho matlafatsa meeli e kantle ea lera ka leng (kahare le kantle) le ho fetela karolong eo ka lipalo tse hlalositsoeng ke mosebelisi. Ho tlatsa isotropic ho etsa unidirectional le likarolo tse ngata matlafatso mokatong o mong le o mong, mme khalase ea fiber ea khabone e ka etsisoa ka ho fetola tataiso ea matlafatso lera. Maano ana a ntlafalitsoeng a nolofalletsa liindasteri tsa lifofane, tsa likoloi le tsa tlhahiso ho kopanya lisebelisoa tse kopaneng mesebetsing ea tsona ka litsela tse ncha. Likarolo tse hatisitsoeng li ka sebelisoa e le lisebelisoa le lihlopha (kaofela ha tsona li hloka fiber e tsoelang pele ea khabone ho etsisa litšepe hantle.), joalo ka lisebelisoa tse qetellong ea letsoho, mahalapa a bonolo le CMM lihlopha.

Ts'ebeliso ea lisebelisoa tsa khalase ea khabone indastering ea likarolo

Lisebelisoa tsa Nylon 12CF, sesebelisoa se secha sa 3D se hatisitsoeng ka carbon fiber se nang le 35% ea fiber fiber, ka hona se setle haholo ho thepa e joalo ka matla a hoqetela a 76 MPa le tensile modulus ea 7529 MPa. Ka matla a feto-fetohang a 142 MPa, ho lekane ho khutlisa tšepe lits'ebetsong tse ngata, ho lekane ho nka sebaka sa lits'ebetso lits'ebetsong tse ngata, ho e etsa hore e be e loketseng liindasteri tsa likoloi, tsa Aerospace le tse ling. Sena fiber fiber e matlafalitsoeng ke thermoplastic e sebelisetsoa ho hlahisa li-prototypes tse phahameng tse ka mamellang liteko tse matla tsa likarolo tsa tlhahiso nakong ea netefatso ea moralo ho fihlela litlhoko tse batloang tsa tikoloho ea tlhahiso mme e ka sebelisoa ho etsa thepa ea thepa moleng oa tlhahiso.

Lisebelisoa tsa OXFAB li hanyetsana haholo le lik'hemik'hale le mocheso, tse bohlokoa bakeng sa ts'ebetso e phahameng ea lifofane le likarolo tsa indasteri. Lintlha tse ngata tsa liteko tsa mochini li bonts'a hore OXFAB e ka sebelisoa bakeng sa likarolo tse felletseng tse loketseng ho sebelisoa bakeng sa khatiso ea 3D. OPM e kenya tšebetsong likonteraka tsa mantlha tsa nts'etsopele le bareki makaleng a lifofane le liindasteri bakeng sa likarolo tse hatisitsoeng tsa 3D bakeng sa lifofane tsa khoebo le tsa sesole, sebaka le lits'ebetso tsa indasteri, tse ka fokotsang boima le litšenyehelo.

Kajeno, lefapha la tlhahiso e tlatselletsang le phatlohile, mme bahatisi ba bang ba fana ka bokhoni ba ho hatisa ka fiber ea khabone. Haeba indasteri ea khatiso ea 3D e batla ho fumana karolo e ngata ea mmaraka 'marakeng oa tlhahiso ea $ 100 billion, theknoloji ea khatiso ea 3D e hloka ho sebelisoa ho mahlale a ts'ebetso le lisebelisoa. Melemo e fapaneng ea fiber ea khabone e bonts'a monyetla oa hore sepheo sena se phethahale. Ho bua 'nete, ho qothisana lehlokoa le moetlo oa tlhahiso, thepa e kopaneng e tla ba e' ngoe ea lisosa tse susumetsang khatiso ea 3D hore e be theknoloji e tsebahalang.

Kopanya le sengoloa sena: Tlhaloso e khutšoane ea theknoloji ea khatiso ea carbon fiber 3D le ts'ebeliso ea eona indastering ea likarolo

Polelo e Hatisitsoeng: Haeba ho se na litaelo tse ikhethang, lingoloa tsohle tse fumanehang sebakeng sena sa marang-rang ke tsa mantlha. Ka kopo bonts'a mohloli oa khatiso: https: //www.cncmachiningptj.com/ li -ththanks!

Services Our

- 5 selekane Machining

- Cnc siloa

- Cnc fetola

- Mechini ea Machining

- Ts'ebetso ea Machining

- Phekolo ea bokaholimo

- Metal Machining

- Machining ea polasetiki

- Phofo Metallurgy hlobo

- Ho Casting

- Likarolo tsa Gallery

Case Studies

- Likarolo tsa Auto Metal

- Likarolo tsa mechine

- Sesebelisoa sa mocheso oa LED

- Likarolo tsa Kaho

- Likarolo tsa mobile

- Likarolo tsa Bongaka

- Likarolo tsa Elektroniki

- Machining e etselitsoeng

- Likarolo Tsa Baesekele

Lethathamo la lintho tse bonahalang

- Aluminium Machining

- Thaethaniamo Machining

- Lisebelisoa tsa Stainless Steel

- Koporo Machining

- Koporo Machining

- Super motsoako Machining

- Peek Machining

- Machining a UHMW

- Tlanya Machining

- Machining a PA6

- PPS Machining

- Mochini oa Teflon

- Inconel Machining

- Sesebelisoa sa Sesebelisoa sa Steel

- Boitsebiso bo Eketsehileng

Likarolo tsa Gallery