Carbide E shoa | Ho shoa ha Batho | Tungsten Carbide E shoa | Extrusion shoa | Batang etsang shoa

Punch, hlobo, hlooho, extrusion, ho taka hoa shoa: RE PTJ. E 'NGOE EA E MOLEMO KA HO FETISISA CHINA CARBIDE E TSOA MOSEBETSI

|

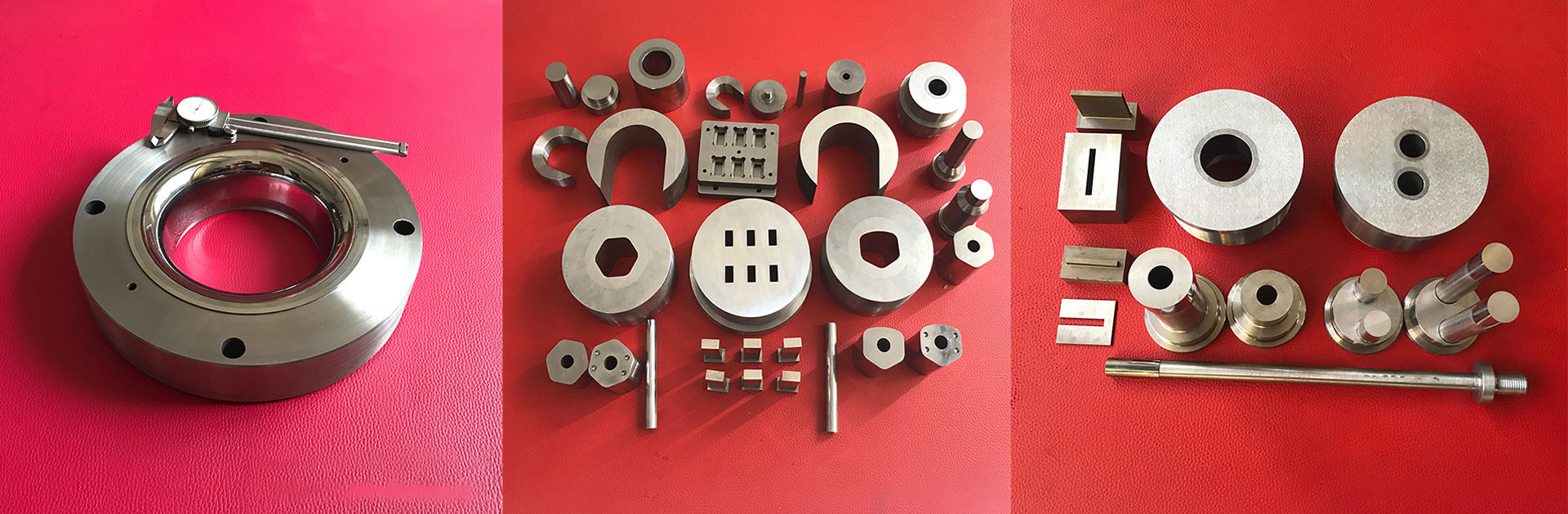

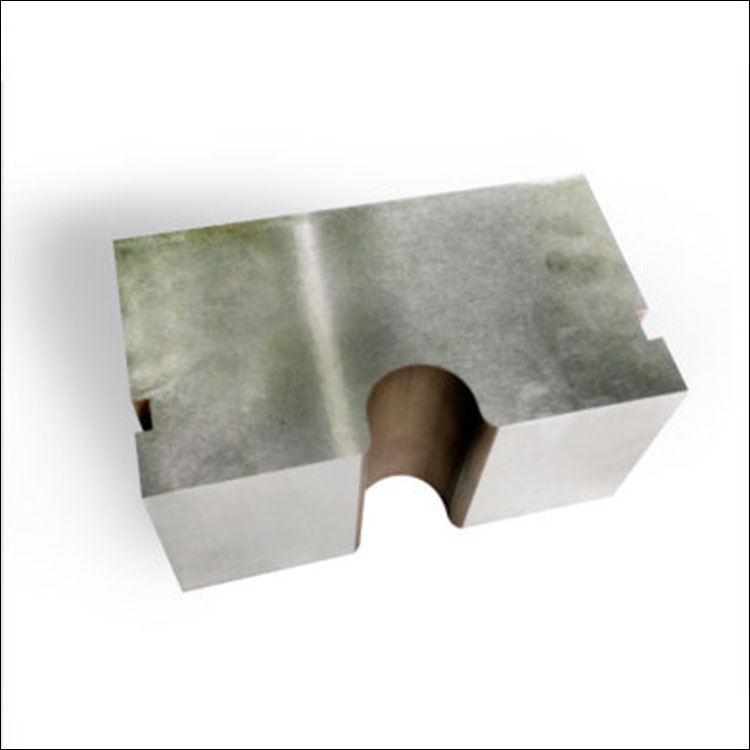

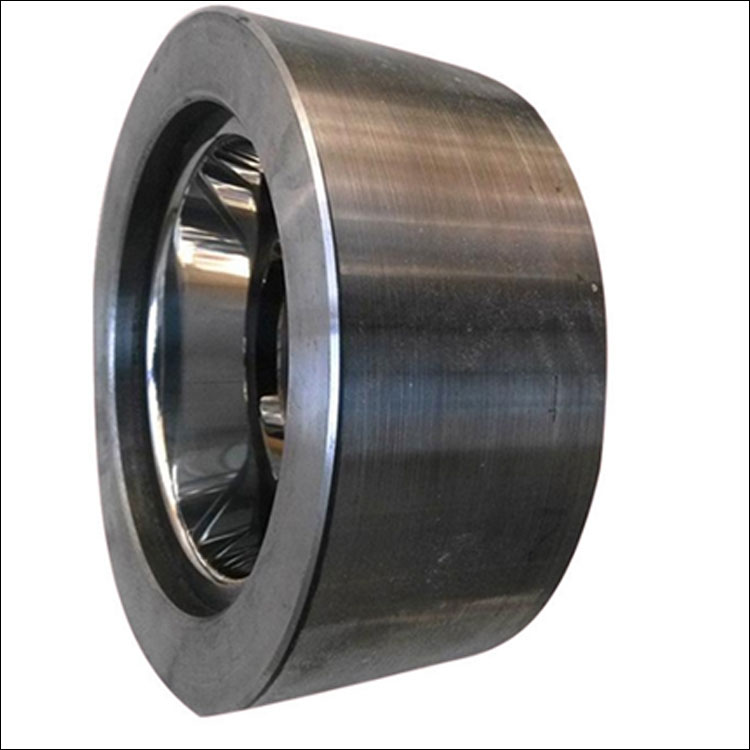

Carbide e shoa ke eng? Carbide e shoa ke karolo ea bohlokoa haholo ho baetsi ba carbide e samente. Hangata lefu la carbide le sebelisitsoeng ka samente le kenyelletsa serame se batang, litebele tse batang lia shoa, li-hexagonal lia shoa, moea oa shoa, joalo-joalo. Carbide e shoa makhetlo a leshome kapa esita le makhetlo a mangata ho feta bophelo ba tšepe bo shoang. Tungsten carbide e shoa e na le thatafalo e phahameng, matla a phahameng, ho hanyetsa ts'enyeho, ho hanyetsa mocheso o phahameng le coefficient e nyane ea katoloso. E bapala karolo ea bohlokoa tlhahiso le ts'ebetso ea carbide e samente.

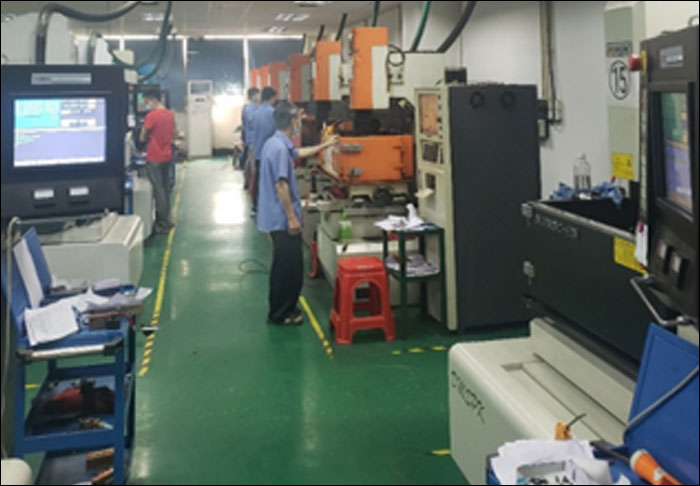

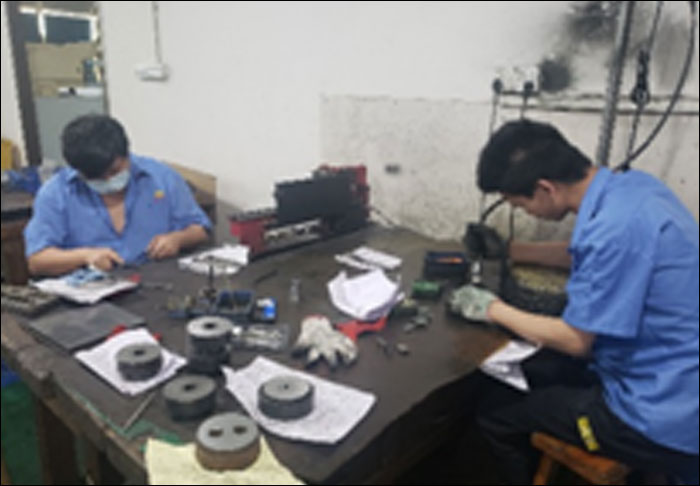

Ha e le moetsi ea tsoelang pele oa china carbide, Cold Forming Die, Drawing Die le Carbide Extrusion Die ke tse ikhethang tsa PTJ. Re ipabola ho hlahiseng sebetsa ka ho nepahetseng, tlhahiso e phahameng e fetoha le maemo TLHOKOMELO makenete a shoa ho fihlela setifikeiti sa ISO 9001: 2015. Ikopanye le rona bakeng sa merero ea hau.

Haeba u batla lihlahisoa tse ntle ka ho fetisisa tse entsoeng ka theko e tlase haholo (theko ka sengoathoana le melemo ea boleng bo holimo), joale u batla ho theha tšepe ea hau u sebelisa PTJ. PTJ Carbide E shoa Lefapha le u tiisetsa mamello e tiileng le lefu le tšoarellang nako e telele - kaofela ka theko e tlase ebile ka nehelano e potlakileng. Ha e le hantle, ka PTJ u fumana lihlahisoa tse ke keng tsa qojoa le ts'ebeletso ea bareki ho tsoa ho litsebi tse tloaelehileng tsa lefu la carbide. Fumana qotsulo ho The Carbide Die Specialists Kajeno! Iteanye le rona

|

|

|

|

|

|

|

|

Ikopanye le rona carbide ea shoa ditshebeletso lienjineri kajeno ho buisana ka lintlha tsa projeke ea hau e rarahaneng.

|

PTJ Carbide Die Manufacturer e ka etsa hore lefu la hau le fihle sehlopheng sefe kapa sefe sa carbide seo u se bolelang, leha ho le joalo, haeba u ka rata tlhahiso, sehlopha sa rona sa litsebi se tla thabela ho u eletsa hore na ke sehlopha sefe se tla tšoaneleha hantle bakeng sa ts'ebetso ea hau. Mohlala, sehlopha se le seng se tla hlahisa likarolo tse ling tse sa hloekeng ha tse ling li tla sebetsa hantle ha li etsa koporo. PTJ e ka sekaseka hore na lefu la hau le tsofala joang 'me ea supa lilemo tsa boiphihlelo ho khothaletsa e nepahetseng carbide ea tungsten molemong oa hau. Ntle le moo, re tla sebetsa le uena ho sekaseka le ho ntlafatsa ts'ebetso ea hau ea lefu ka ho fana ka maikutlo le liteko. Tse latelang ke indasteri le litaelo tsa lihlahisoa tseo re ka u etsetsang tsona (hlokomela: re etsa feela lefu, ebile ha re na bokhoni ba ho u etsetsa lihlahisoa)

-

• Masale a Annular

-

• Li-Stud tsa Ball

-

• Litšiea

-

• Lihlahisoa tsa Carbide Bushings

-

• Linyeoe

-

• lithipa tse sehiloeng

-

• shoa hammoho

-

• Ho shoa ha litene

-

• Ho betla Bushings

-

• Li-Roll Roll

-

• Litlatsetso

-

• Li-Wafers tsa Hex

-

• Lisebelisoa tsa Carbide Die

-

• Li-mandrels

-

• Li-Nibs

-

Lithakhisa (Carbide)

-

• Ho shoa ha Carbide Point

-

• Ho shoa ha litempe tse tsoelang pele

-

• Liketsahalo tsa litebele

-

• Likotlo tsa Carbide

-

• Litšitiso

-

• Litšebeletso

-

• Li-Extrusions tse khethehileng

-

• Khoele e shoa

-

• Fetisetsa menoana

-

• Maraba a ntšitsoeng

-

• Trilobes le tse ling tse ngata!

|

|

|

|

|

|

High ho nepahala ha eona

|

Quote e potlakileng le Ts'ebeletso

|

Fast Delivery

|

Tloaelo e Fela

|

Sebetsa ka ho nepahetseng mechine

|

Litšebeletso tsa Tlatsetso

|

|

Kemiso ea Carbide e shoa

|

Carbide e shoa khafetsa e na le: lihlooho tse batang lia shoa, litebele tse batang lia shoa, terata ho taka hoa shoa, Likhutlo tse 'nè le theknoloji ea tlhahiso ea hlobo ea carbide: joalo ka thepa e tloaelehileng ea mmaraka YG3, YG6, YG6X, YG8, YG15, YG20, YG20C, YG25 le HU20, HU222, HWN1 ), jj., re sebelisa thepa ea mantlha ea carbide, khatello e tlase Mekhoa e ikhethang e kang ho sintering e tla ba le boima bo fetang ba tlhahiso e tloaelehileng, 'me bophelo ba ts'ebeletso bo tla eketsoa ka makhetlo a 3-5. :

-

Mofuta oa pele ke samente carbide terata kotokaka shoa, mofuta ona oa shoa shoa boholo ba samente carbide shoa. Mefuta ea mantlha ea ho taka terata e shoa naheng ea heso ke YG8, YG6, YG3, e lateloe ke YG15, YG6X, YG3X, mme ho hlahisitsoe lihlahisoa tse ling tse ncha, joalo ka mofuta o mocha oa YL bakeng sa ho taka terata e lebelo le terata. shoa brand CS05 (YLO. 5) e tsoang kantle ho naha. CG20 (YL20), CG40 (YL30); K10, ZK20 / ZK30.

-

Mofuta oa bobeli oa hlobo ke hlooho e batang, ho phunya ho batang le ho bopa hlobo. Lihlahisoa tsa mantlha ke YC20C, YG20, YG15, CT35, YJT30 le MO15.

-

Mofuta oa boraro oa hlobo ke hlobo e sa sebeliseng matla a khoheli e sebelisetsoang ho hlahisa lisebelisoa tsa matla a khoheli, joalo ka YSN ea letoto la YSN (ho kenyelletsa 20, 25, 30, 35, 40) le sebopeho sa tšepe se se nang matla a khoheli sehlopheng sa TMF .

-

Mokhahlelo oa bone ke hot hot die die. Ha ho na boemo bo tloaelehileng bakeng sa mofuta ona oa alloy, mme tlhoko ea mmaraka e ntse e eketseha.

|

|

|

|

Tenyetsehang Magnetic-shoa

|

Cold-etsang-shoa

|

Tungsten-Carbide-E shoa

|

Carbide-litebele

|

|

Lisebelisoa Tse Sebelisitsoeng Hangata Bakeng sa Lefu la Carbide

|

Ho na le mefuta e mengata ea likarolo tsa carbide tse nang le mesebetsi e fapaneng, ka hona ho na le mefuta e mengata ea lisebelisoa tse sebelisitsoeng. Ka tlhaiso e tsoelang pele ea lisebelisoa tse ncha, lisebelisoa tsa lefu li lula li nchafatsoa. Ho latela maemo a fapaneng a ts'ebetso, lisebelisoa tsa shoa li ka aroloa ka: thepa e entsoeng ke tšepe mocheso o tloaelehileng (boemo bo batang), bo bitsoang batang eaba ba etsa shoela'ng tšepe; thepa e thehiloe tlasa boemo ba ho futhumatsa, e bitsoang chesang mosebetsi carbide shoa. Hajoale, lisebelisoa tse sebelisoang lefung li kenyelletsa lisebelisoa tse fapaneng tsa lisebelisoa tsa khabone, lisebelisoa tsa lisebelisoa tsa alloy, litšepe tse lebelo le phahameng, litšepe tse entsoeng ka tšepe le carbides (kenyeletsa TLHOKOMELO Tenyetsehang Magnetic).

-

Steel Sesebelisoa sa k'habone se na le khabone e ngata e nang le khabone ea 0.7% ho isa ho 1.4%. Limaraka tsa mantlha ke T7, T7A, T8, T8A, T10, T12, T12A, jj. Mofuta ona oa tšepe o na le ts'ebetso e ntle ea ho itšeha, ho thatafala ho hoholo le ho hanela ho roala hantle kamora ho tima, empa ho thatafala ha eona ho futsanehile, ho tlameha ho tima nakong ea ho tima , ho senyeha le ho petsoha ho atisa ho ba kholo, botsitso ba tempering bo bobe, mme thatafalo ea mocheso e tlase. E loketse ho etsa hlobo e batang ea mosebetsi o nang le boholo bo bonyenyane le sebopeho se bonolo.

-

Tool Sesebelisoa sa tšepe ke tšepe e qhibilihisitsoeng ka ho eketsa e le ngoe kapa likarolo tse 'maloa tsa alloying motheong oa tšepe ea khabone. Lisebelisoa tsa sesebelisoa sa carbide die tse sebelisoang hangata li kenyelletsa sesebelisoa se tlase sa tšepe le sesebelisoa se phahameng sa tšepe.

-

▶ Hajoale, tšepe ea lebelo le phahameng ea tungsten (WC) W18Cr4V le tšepe e lebelo le phahameng ea molybdenum (MoC) W6Mo5Cr4V2 e sebelisoa khafetsa. Lisebelisoa tse phahameng haholo li na le hardenability e ntle, e ka thatafatsoa moeeng, 'me e ntse e boloka ho thatafala ho hoholo, matla a phahameng, ho ba thata hantle le ho roala ho hanyetsa hoo e ka bang ka 600 ° C. Lisebelisoa tse phahameng haholo li loketse ho etsa mohatsela extrusion oa shoa.

|

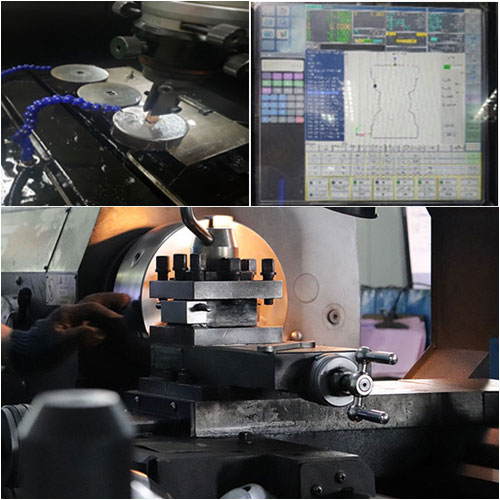

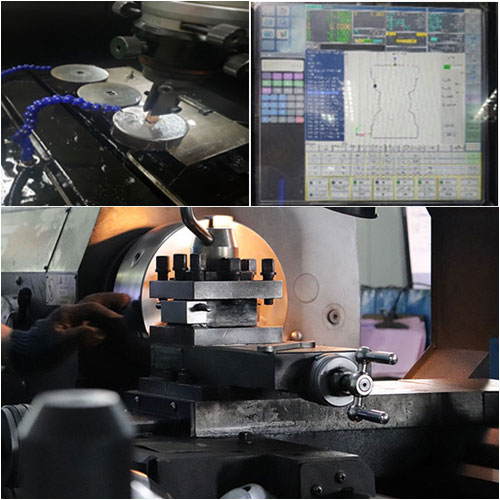

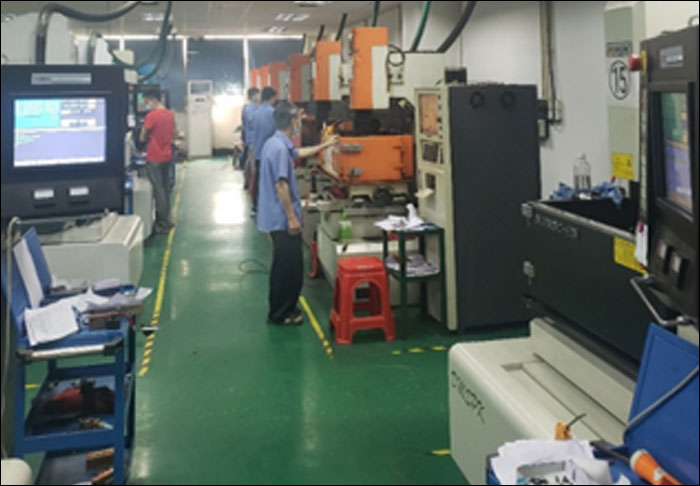

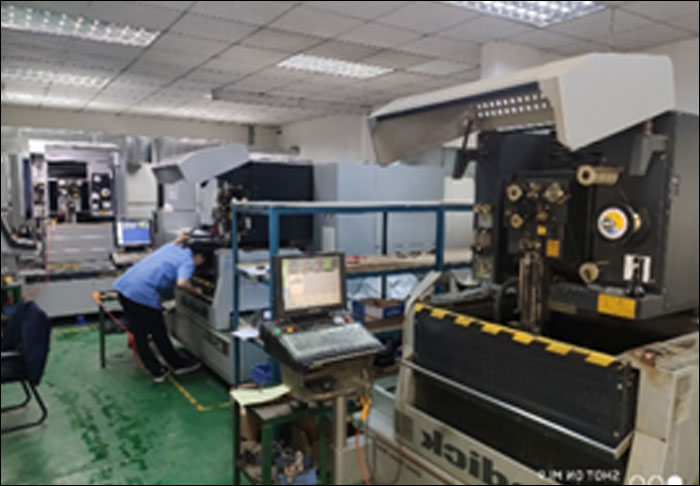

Ts'ebetso ea rona ea ho shoa ha Carbide le Ts'ebetso ea Carbide e shoa

|

|

|

|

|

Mochini oa EDM

|

Kakaretso lathe sebetsa

|

Ho sila le ho bentsa

|

Mochini oa ho sila

|

|

|

|

|

ho bentsa

|

Sebetsa ka ho nepahetseng ho sila

|

microscope ea setsebi

|

Ho sebetsa butle ka terata

|

CARBIDE E shoa LITHUTO TSA KETSAHALO

Sheba theknoloji e eketsehileng ea machining ho rona Leqephe la Gallery

PTJ esale e sebeletsa bareki lefats'eng lohle ho tloha ka 2007. Re lula re chorisa litsebo tsa rona le ho ntlafatsa lisebelisoa tsa rona ho netefatsa hore bareki ba rona ba khotsofetse. Re na le bareki ba bangata ba tšepahalang ba sebelitseng le rona ka lilemo tse fetang 10. Ha re shebeng theknoloji e ngoe ea machining mme re ithute ho eketsehileng ka PTJ Hardware.